On February 22, 2023, Mohou.com learned that some 3D printing customers shared how HP Multi Jet Fusion (MJF) technology helped them profitably.Expand the production scale of plastic parts efficiently.

△HP collaborates with L’Oréal to increase production flexibility and create innovative new packaging and customer experiences

With the HP Jet Fusion 5200 and Jet Fusion 5420W industrial 3D printers, manufacturing users can produce final parts with high repeatability while optimizing costs and productivity. According to HP, these industrial 3D printing systems increase in efficiency per cubic inch due to the benefits of high productivity, automation, predictability and material reuse that save labor and cost costs. materials.

Since their launch, many users, ranging from producers of robots and mechanical parts to 3D printing service providers such as DI Labs, Prototal Industries and Weerg, have revealed the advantages of these industrial 3D printers to meet the different needs of production. Didier Deltort, President of Personalization and 3D Printing at HP, said: “3D printing technology addresses the most pressing needs of today’s market, including sustainable innovation, hyper-personalization and resilience. businesses. With our global network of partners and customers, we continue to grow. this technology to meet new market demands.

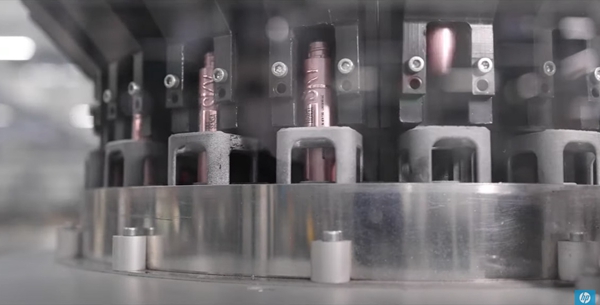

△A set of HP Jet Fusion 5200 industrial 3D printers in the production workshop

HP industrial 3D printer

Since its introduction in 2014, HP’s proprietary MJF technology has been used in a wide range of industries, including aerospace, medical, automotive, education, consumer products, and manufacturing services, with more than 170 million pieces printed. As customer demand in new industries increases, the company continuously expands its industrial 3D printer product line, launching new products such as Jet Fusion 5200 and 5420W in recent years to meet the production needs of different industries.

Launched in 2019, the HP Jet Fusion 5200 is touted as a factory-ready system capable of meeting industrial 3D printing needs. It includes a build unit, a processing station and a cooling unit and is designed to provide higher profitability for 3D printing in production environments. reliability, performance and quality of parts.

According to HP, the machine has a printing speed of up to 5,058 cubic centimeters per hour and a print volume of 380 x 284 x 380 mm, making it extremely economical. HP believes this claim to be true because the system is not only highly productive (over 160,000 cubic centimeters per day), but also has a strong portfolio of ancillary products that automatically mix materials, while integrating software to streamline user workflows.

Moreover, the software advantage of HP Jet Fusion 5200 industrial 3D printing solution is not only the integrated dashboard, it can also organize data from multiple management systems. In this way, users can more easily optimize workflow, improve work efficiency and extend it to industrial production.

△3D printed model of a twisted fracture produced using the HP Jet Fusion 5420W 3D printing solution

Targeting the industrial 3D printing market, HP Jet Fusion 5420W is the latest model launched at Formnext last year, becoming the first industrial-grade MJF solution in the Jet Fusion 5400 series for home appliance production. The machine offers industrial-grade reliability, low cost and improved manufacturing predictability.

At Formnext, HP demonstrated how its industrial 3D printing technology can help customers such as DI Labs, Prototal Industries and Weerg solve problems related to innovative white applications. According to Jan Löfving, CEO of Prototal, customers have shown strong interest in new white applications due to the addition of the HP Jet Fusion 5420W. In fact, the 5420W already offers these users industrial-grade reliability, low cost and improved manufacturing predictability.

Carl Douglass, co-founder of DI Labs, another user of the HP Jet Fusion 5420W system, added: “The new HP Jet Fusion 5420W industrial 3D printer brings more valuable tools to our toolbox for healthcare applications where white pieces are essential. “

△HP said 3D printed white parts have huge market prospects, such as in the automobile industry

Where are HP’s industrial-grade 3D printing applications?

The company’s industrial-grade 3D printing applications are used by manufacturers across multiple industries, from tooling to final aftermarket manufacturing. With HP Jet Fusion industrial 3D printers, manufacturers can produce parts with optimized mechanical properties without long lead times.

HP Jet Fusion is considered ideal for 3D printing applications in automotive, consumer goods, healthcare and industrial. The new HP Jet Fusion 5420W series has proven to be a popular solution with early adopters of white applications. In fact, Prototal Industries, a member of HP’s Digital Manufacturing Network (DMN), praised the system for “enabling them to take on bold and innovative new customer projects.” In addition to the industrial grade products offered by HP, we are also seeing immediate interest in the new white applications enabled by the latest addition to the HP Multi Jet Fusion family.

At Formnext 2022, HP also demonstrated more innovative applications, including mass-produced spoiler seals from GKN Additive, designed to improve fuel efficiency. Meanwhile, Smith Optic’s MAG Imprint 3D glasses also debuted at the show, using the HP MJF 3.3D printing technology.

Source: Internet

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.