As a leading manufacturer of precision parts, great light understands the importance of minimizing deformation in CNC machining. Deformation can lead to inaccurate parts, reduced product quality and increased production costs. In this article, we will dig into the world of CNC machining deformation and explore its causes, effects and prevention methods.

Understand CNC machining deformation

CNC machining deformation refers to adverse changes in the shape or size of the workpiece during or after processing. This may be due to various factors, including material properties, processing parameters and tool conditions. Deformation can be manifested in different forms, such as bending, warping or distortion, and may be caused by internal stress, thermal expansion or mechanical loading.

Causes of CNC processing deformation

Several factors can cause CNC processing deformation, including:

- Material properties: The inherent characteristics of the material being processed, such as its elasticity, hardness and thermal expansion coefficient, may affect its sensitivity to deformation.

- Processing parameters: Cutting speed, feed rate and cutting depth will affect the heat generated and the deformation generated.

- Tool Conditions: The design and condition of the cutting tool, including its geometry, materials and wear, may affect the processing process and cause deformation.

- Clamping and fixing: Inadequate clamping or fixing may cause the workpiece to move or distort during processing, resulting in deformation.

Effects of CNC machining deformation

Deformation can have a significant impact on the quality and availability of the finished part. Some effects of CNC machining deformation include:

- Inaccurate dimensions: Deformation can cause deviations from the expected dimension, making the parts unusable or require expensive rework.

- Reduced product quality: Deformation may damage the structural integrity and performance of the part and may lead to premature birth or failure.

- Increase production costs: Deformation can lead to scrap parts, rework and other processing steps, thereby increasing production costs and lead time.

Prevention and minimization of CNC machining deformation

To minimize deformation, several strategies can be used, including:

- Optimize processing parameters: Adjusting the cutting speed, feed rate and cutting depth can help reduce heat generation and pressure.

- Select the appropriate tool: Choose the right cutting tool material, geometry and design can help minimize deformation.

- Improved clamping and fixing: Ensure proper clamping and fixing techniques can prevent workpiece movement and distortion.

- Use deformation reduction techniques: Techniques such as vibration damping, application of coolant and buoyancy processing can help reduce deformation.

in conclusion

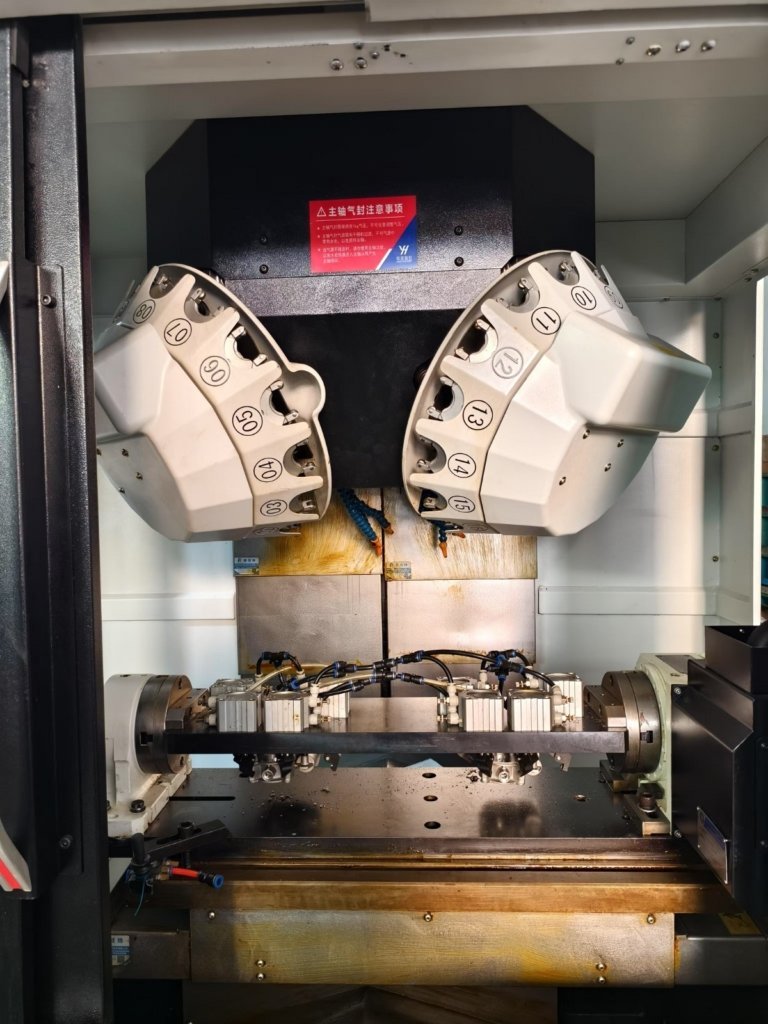

CNC machining deformation is a key issue that may affect the quality and availability of precision parts. By understanding the causes and effects of deformation, manufacturers can take steps to prevent and minimize their occurrence. We use advanced five-axis CNC machining equipment and production technology to professionally solve metal parts manufacturing problems. Our team of experts is committed to delivering high-quality precise parts with minimal deformation to ensure our customers get the best product.

FAQ (FAQ)

Q: What is CNC processing deformation?

Answer: CNC processing deformation refers to adverse changes in the shape or size of the workpiece during or after the processing process.

Q: What are the common causes of CNC processing deformation?

Answer: Common causes of CNC machining deformation include material properties, processing parameters, tool conditions, and clamping and fixing.

Q: How to prevent or minimize CNC processing deformation?

A: Strategies to prevent or minimize deformation include optimizing machining parameters, selecting appropriate tools, improving clamping and fixing, and using deceleration techniques.

Q: What are the consequences of CNC processing deformation?

Answer: Deformation will lead to inaccurate dimensions, reduce product quality and increase production costs.

Q: How to solve CNC machining deformation with excellent light?

A: We use advanced five-axis CNC machining equipment and production technology to professionally solve metal parts manufacturing problems, thereby ensuring deformation and high quality precise parts.