Unlocking innovation: Master the upper assembly of CNC aluminum adhesive solutions

In a world of precision-driven manufacturing, innovation often requires pushing boundaries. For complex designs, large structures or scenarios where specific material properties are required, bonded CNC machining aluminum components are often the cleverest solution. Although CNC machining excels in creating complex, highly resistant individual parts, bonding unlocks new dimensions of design possibilities and manufacturing efficiency. At Greatlight, we use advanced five-axis machining capabilities and deep material completion expertise to provide our customers with powerful and reliable aluminum collaboration solutions.

Why combine CNC aluminum parts? It’s not just about sticking things together.

Modern manufacturing is not always about carving a piece of metal. Choosing strategically machined aluminum components has compelling advantages:

- Conquer complex geometric shapes: Five-axis CNC machining allows the creation of highly complex subassemblies, but sometimes the final geometry required exceeds the machine envelope, or involves complex internal structures that cannot be machined single elastically. Bonding makes these parts assemble into their final complex form.

- Weight optimization and material savings: It is common to bond lightweight aluminum structures such as trusses or honeycomb cores to the skin in aerospace and automobiles. It achieves a much higher ratio of high strength than processing from solids, reducing material waste and cost.

- Design freedom and functionality: Integrating different materials (e.g., aluminum bonds bonded to composites, specific plastics, or even other metals) becomes feasible, allowing designs to take advantage of the unique properties of each material. Bonding can also embed the sensor or seal directly into the assembly.

- Cost-effective: For large parts or complex designs, investments with huge machining centers or compromised processing may be cheaper if you invest in a compromised machining center. It also minimizes expensive raw material use.

- Pressure distribution and performance: Compared to mechanical fasteners, carefully designed adhesive joints can distribute stress more evenly on the bonding line, resulting in potentially better fatigue and sealing properties (important for fluid or pressure applications).

Challenge: Bonding aluminum is not trivial

Aluminum has a major obstacle to adhesives: its oxide layer. Although the oxide layer is inherent and protective, it may be weak, porous, and has poor bonding to the base metal. Applying glue alone to unwashed aluminum almost certainly results in weak, unreliable joints.

The main challenges include:

- Surface pollution: Oil, grease, cutting liquid (even after processing), dust and fingerprints can greatly reduce bond strength.

- Inconsistent oxide layer: The thickness and structure of the natural oxide layer may vary, resulting in unpredictable adhesion.

- Adhesive selection: The wrong binder chemistry is caused by the selection of the wrong binder chemistry for the specific aluminum alloy, operating environment (temperature, chemicals, moisture) and expected loads (shear, peel, cracking).

- Joint design and preparation: The geometry of the bonding area (ring joints, joints, etc.), surface roughness (implemented by a specific CNC finish), precise clearance control between parts is crucial.

- Curing process: Many high-performance adhesives require precise temperature, pressure and time control during curing to produce full strength.

Greatlight’s solution: Precise machining conforms to expert bonding capabilities

This is the glow of Greatlight’s integrated approach. We are not just machine parts; we see the bonding process as a key extension of manufacturing operations, requiring the same level of accuracy and control.

- Expert processing for the best bonding: Our five-axis function produces near-mesh components with excellent dimensional accuracy. Crucially, our machine surfaces are destined to bond with specific toolpaths and parameters to promote optimal adhesion – ensuring the correct surface profile without excessive residual stress. It is crucial that we understand features such as bond line thickness control pockets.

- Precise surface preparation: It can be said that this is the most critical step.

- We use carefully cleaned processing components that ensure the removal of traces of all processed oils and contaminants without the need to disperse residues.

- We employ precise surface treatments tailored for adhesives and applications: controlled wear (gravel blasting) for macroscopic conflicts, chemical etching and oxide layer modifications for micro-cutting, or specialized startup to enhance chemical bonding.

- A stringent protocol ensures that prepared parts are treated with only clean gloves and bonded promptly before any surface degradation occurs.

- Science-based adhesive selection and application: We work with leading adhesive manufacturers and have extensive in-house knowledge. We have no guesses; we choose the adhesive according to:

- Aluminum alloy: Recognize the differences between 6061, 7075, 5052, etc.

- Conditions of service: Extreme temperature, chemical exposure (fuel, lubricant, solvent), humidity, UV exposure.

- Load requirements: Static strength, fatigue resistance, impact resistance, and flexibility is required.

- Process requirements: Healing time, fixed demand, pot life.

- Common types: High-strength epoxy resin, tough acrylate, structural silicone, durable polyurethane, heating film adhesive.

- Controlled assembly and curing:

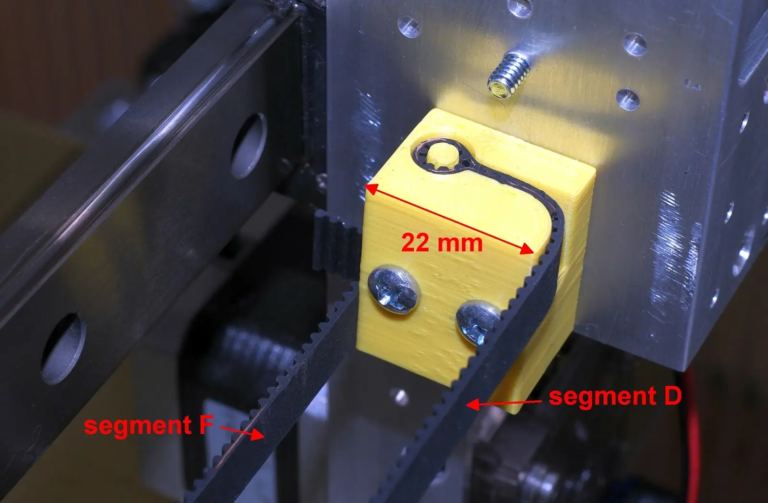

- Align parts with special fixtures designed in our store to match our machining features with tolerances, ensuring a perfect finish and controlled bond line thickness – a key factor in joint strength.

- We use technology to carefully apply adhesives to ensure consistent, ineffective coverage.

- Curing is performed under precisely controlled conditions (time, temperature, pressure), as specified by the adhesive manufacturer’s specifications and our strict QA protocol. This may involve a programmable curing oven or pressing.

- Integrated post-processing and completion: Bond Parliament is a new entity. We provide a full range of completion services at these meetings:

- Dimensional verification and metrology: Confirm that the final assembly meets all critical dimensions and tolerance stacks.

- Remove adhesive flash: Precise machining or trimming to clean the edges.

- Surface finish: Apply anodized, powder coating, paint or other finishes throughout the bonding assembly as needed to ensure aesthetics and enhanced environmental protection. We manage the complexity of masking pre-assembled parts.

- Non-destructive testing (NDT): In critical cases, techniques such as ultrasound testing can be used to check the integrity of the bonded joint below the surface.

Why Greatlight is your ideal partner CNC Aluminum Cooperation

- Deep materials and process knowledge: We combine our expertise in CNC machining aluminum with a professional understanding of adhesion science and surface chemistry.

- Five-axis accuracy: The basic accuracy part is created for the perfect assembly that is essential for a strong bond.

- End-to-end control: Supervising every step of CNC machining, surface preparation, bonding, curing and final finishing under one roof ensures process consistency, traceability, and eliminates compatibility issues between suppliers.

- Quality Commitment: At each stage, there are strict quality inspections and are supported by complex metrology equipment.

- Solution Oriented: We work with you to browse design complexity and optimize manufacturing, whether it’s prompting the capabilities of strengthening bonds or assembly strategies.

- Speed and efficiency: Our integrated approach simplifies the process and speeds up your time to market.

Conclusion: In addition to processing, we move towards engineering components

CNC aluminum bonding is not only an assembly step; it is an advanced manufacturing strategy that enables lighter, more powerful, more complex and more cost-effective products. Success depends on combining precise processing with detailed surface science and adhesive expertise. At Greatlight, this comprehensive approach is our core strength. Our advanced five-axis CNC capabilities set the stage for geometric perfect components, while our controlled processes for cleaning, surface engineering, precise adhesive application, curing and finishing ensure that bonds meet the most demanding performance standards. Whether it’s aerospace, high-performance cars, advanced robotics, or specialized industrial applications, working with Greatlight can access the full potential of bond structures. Let us help you go beyond traditional manufacturing boundaries and unlock the next level of your design vision with an excellent combination of CNC machining and engineering.

FAQ: CNC aluminum adhesive solutions

Q1: Why can’t I just use regular super glue or epoxy from hardware stores to bond my CNC aluminum parts?

A: Although basic adhesives may offer some temporary holdings, they lack the specific formulas required to bond to the aluminum structure. Designed by specific chemical distributions (epoxy, acrylate, polyurethane), professional structural adhesives can better adhere to properly prepared aluminum surfaces, providing great strength, toughness, heat resistance and environmental durability required for engineering applications. Off-the-shelf glue usually fails under load, temperature changes or moisture exposure.

Q2: How critical is the surface preparation before bonding aluminum?

one: Extremely critical. It is often said that when working with metals such as aluminum, the bond strength is more about surface preparation than the adhesive itself. Ignore thorough cleaning, degreasing and proper surface treatment (such as wear or etching) are the main causes of bond failure. Natural alumina layer and processed residues create weak boundary layers. Proper preparation can eliminate this obstacle and create a high-energy surface for mechanical and/or chemically locked adhesives.

Q3: How does CNC processing quality affect bond strength?

Answer: The quality of CNC processing is basic. Poorly machined surfaces, with too many tool traces, burrs, inconsistent flatness or inaccurate dimensions, will create stress concentrations in the bonding joints and make it impossible to achieve consistent, controlled bonding line thickness. Greatlight’s high-precision five-axis machining ensures that the part blends perfectly with the definition gap required by a specific adhesive and more efficiently withstand the expected load.

Q4: Can bonded aluminum joints be as strong as welded or mechanically fixed joints?

A: Yes, it is usually stronger in a specific way, especially when designed correctly. The structural adhesive distributes the load evenly throughout the bond area, thereby reducing the stress concentration at the weld point or fastener holes. This can lead to fatigue resistance. While the maximum final tensile strength or shear strength may be comparable to good welds/bolts in many applications, bonded joints have especially modern tempered adhesives designed to resist peels and cutting forces that can brittle welds. The choice depends on the specific design requirements.

Q5: What types of finishes can be used after bonding?

A: We provide comprehensive post-processing, including:

- Cleaning and flashing: Accurate burrs and remove excess adhesive.

- Anodized (type II, type III/hard coating): Ideal for corrosion resistance and surface hardness.

- Powder coatings and paintings: Durable and beautiful choice.

- Bead Blasting and Brushing: Used for specific surface textures.

In the process, we carefully cover up the critical areas as needed. Choosing a finish that is combined with aluminum and bonds is part of our professional consulting services.

Question 6: How does Greatblight ensure the quality and strength of the bonded joint?

A: The quality has been embedded in our process:

- Controlled environment: Precise cleaning, preparation and curing conditions.

- Process control: Comply with strict protocols for material handling, surface treatment, bonding mixing (if applicable), application and curing (temperature, pressure, time).

- fixed: Custom fixtures to ensure accurate alignment and controlled keyline thickness.

- Process Check: Visual inspection during assembly.

- Final metrology: Comprehensive size verification of components.

- Destructive and NDT (optional): We can perform witness sample tests or recommend non-destructive tests of critical components (such as ultrasound) to verify the integrity of internal keys.

Question 7: Is Greatlight helpful in design?

Answer: Absolute. It is ideal to participate as soon as possible. Our engineers can recommend:

- Optimize the geometry of parts and Strong bonding (suggested joint design, fillet/rounded corners, surface finishing requirements).

- Material selection compatibility.

- Define the actual tolerances for bond gaps.

- Integrate functions that benefit the alignment during assembly or meet curing process requirements. Consulting with us during the design phase leads to the most manufacturing, robust and cost-effective bonding solutions.