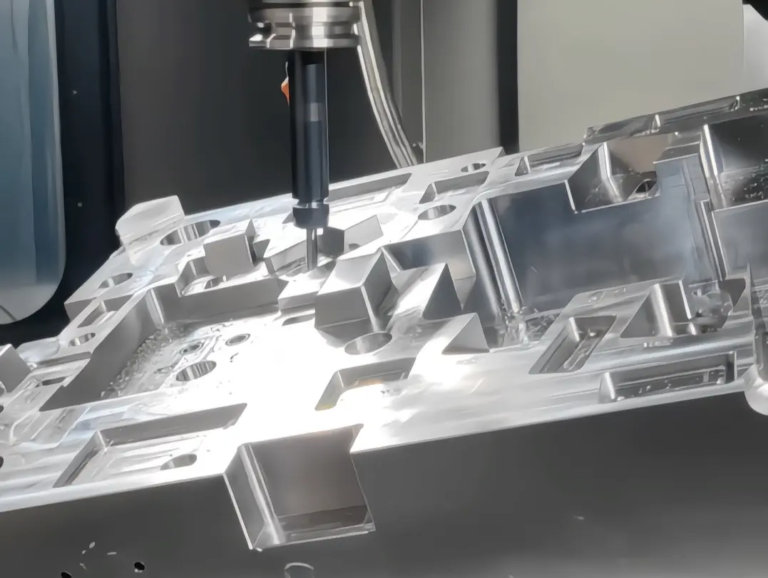

Cheap CNC machining: 5 affordable options

In today’s highly competitive manufacturing environment, businesses are always looking for ways to reduce costs without damaging quality. This can be a major challenge when it comes to CNC machining. However, with the right strategies and options, you can achieve high-quality precision machining at an affordable price. In this article, we will explore the 5 most affordable options for cheap CNC machining.

Option 1: Online CNC machining service

In recent years, online CNC processing services have become increasingly popular. These services allow you to upload design files and receive machining parts within a few days, often a fraction of the cost of traditional CNC machining. With the online service, you can choose from a wide range of materials including aluminum, steel and titanium and enjoy fast turnaround times and competitive pricing.

Option 2: Local CNC machining store

The local CNC processing shop offers another affordable option for businesses that do not require mass production. These stores often have experienced mechanics and state-of-the-art equipment, allowing them to produce high-quality parts quickly and efficiently. By working with local stores, you can reduce shipping costs and ensure faster production times.

Option 3: 3D printing

Additive manufacturing or 3D printing has revolutionized manufacturing. With 3D printing, you can quickly and affordably complex parts and prototypes. Although this technology is still evolving, it provides a cost-effective way to produce small and medium-sized parts.

Option 4: Open Source CNC Processing

Open source CNC machining provides another affordable option for businesses with limited budgets. This option gives you access to free or low-cost CNC machining software and equipment that can be modified and customized to suit your specific needs. By leveraging open source technology, you can reduce costs and increase productivity.

Option 5: Use or refurbish CNC machining equipment

For businesses with limited equipment budgets, using or renovating CNC machining equipment may be a viable option. These machines may be much cheaper than buying new equipment, and with proper maintenance and upgrades, high-quality parts can still be produced.

in conclusion

In short, cheap CNC machining is possible with the right strategy and choice. By exploring online CNC machining services, working with local stores, using 3D printing, leveraging open source technology or investing in second-hand or refurbished equipment, businesses can achieve high-quality precision machining at affordable prices.

FAQ

Q: How much does a machine cost in the used CNC processing industry?

A: The cost of using CNC machining equipment may vary considerably depending on the machine, manufacturer and condition. Typically, you can expect to pay $5,000 to $50,000 for a used CNC mill or lathe.

Q: Can I use open source software for CNC machining?

A: Yes, there are several open source CNC machining software options available, including Freecad, Opencam, and CGX. These software options are free to use and can be modified and customized to suit your specific needs.

Q: How to choose the right online CNC processing service?

A: When choosing an online CNC processing service, please consider factors such as production capacity, material selection and customer service. Looking for a service that provides competitive prices, fast turnaround time and reputation for producing high-quality parts.

Q: Can I use a local CNC machining store for prototype production?

A: Yes, a local CNC processing store may be a great choice for prototype production. They often have experience in small batch orders and can provide fast turnaround times and competitive prices.