3D Resin Printer Bed Plate Magnet: A Comprehensive Guide

3D printing has revolutionized multiple industries by enabling rapid prototyping, custom part production, and small-batch manufacturing. Among the various components that ensure the precision and reliability of a 3D resin printer, the bed plate magnet plays a crucial role in maintaining a stable and efficient printing environment. This guide delves into the technical parameters of bed plate magnets used in 3D resin printers, installation and use precautions, and details on how to replace them. Additionally, we will explore the types of bed plate magnets, their material compositions, performance indexes, and advantages/disadvantages in a tabular format.

Understanding the Technical Parameters of 3D Resin Printer Bed Plate Magnets

What is a 3D Resin Printer Bed Plate Magnet?

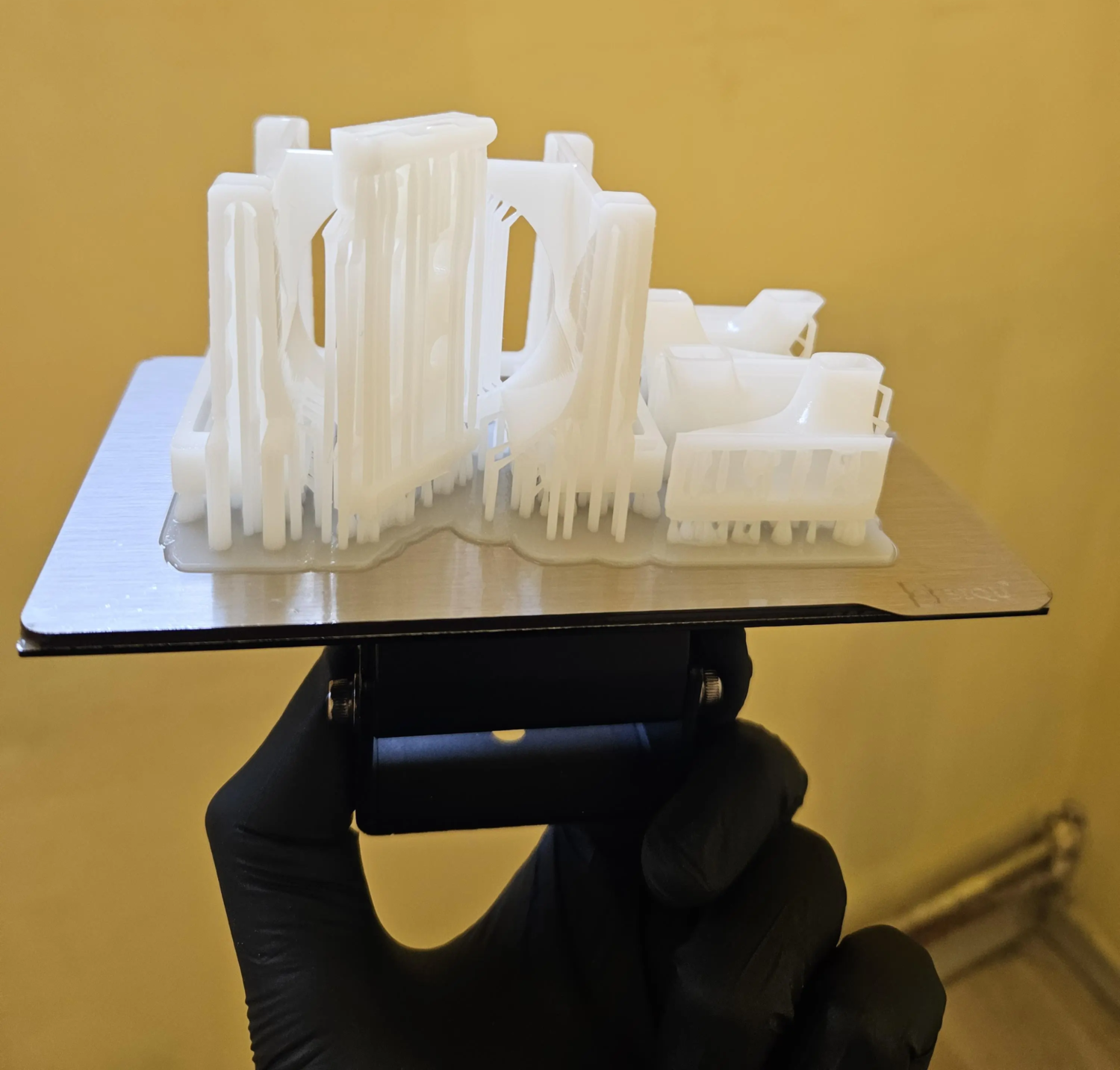

A bed plate magnet in a 3D resin printer is an essential component that ensures proper adhesion of the printed resin to the printing surface during the printing process. It typically features a magnetic base that attaches securely to the printer bed, offering flexibility when changing or removing print plates. These magnets are specially designed to withstand the heat and pressure associated with resin printing.

Key Technical Parameters:

- Magnetic Force: Determines how strongly the bed plate magnet holds the print bed in place. This is measured in Gauss or Tesla units.

- Temperature Tolerance: Most 3D resin printer bed plate magnets can handle temperatures up to 100-150°C, depending on the resin used and the printing conditions.

- Material Composition: Composed of materials such as neodymium, ferrite, or samarium-cobalt, which dictate the magnet’s strength and durability.

- Dimensions: Bed plate magnets come in various sizes to fit specific printer models, ensuring the perfect fit for each printing setup.

- Coating and Surface Treatment: Typically, these magnets are coated to prevent rust and degradation. Common coatings include nickel, zinc, or epoxy resin.

- Durability and Lifespan: The longevity of bed plate magnets is affected by factors like the frequency of use, operating temperature, and the type of materials printed.

Installation and Use Precautions

Installation Steps:

- Clean the Bed Surface: Before attaching the bed plate magnet, ensure that the printer’s bed surface is clean and free of dust or debris.

- Align the Magnet Correctly: Carefully align the magnetic plate with the print bed, ensuring it fits securely without gaps.

- Ensure Strong Adhesion: Press down on the magnet firmly to ensure full adhesion. For magnetic bases with self-adhesive layers, apply pressure to avoid air bubbles.

- Check Leveling: After installation, check the bed leveling to ensure the magnet does not interfere with the calibration process.

Usage Precautions:

- Avoid Overheating: Excessive heat can demagnetize the bed plate magnet. Always check that the temperature settings are within the recommended limits.

- Avoid Contact with Strong Magnetic Fields: Strong external magnetic fields can disrupt the functionality of the magnet, so store the printer away from other magnetic devices.

- Do Not Use Abrasive Cleaning Agents: When cleaning the magnet, avoid abrasive cleaners that could damage the surface or coating.

- Handle with Care: While bed plate magnets are generally durable, mishandling or dropping them may result in breakage or weakening of the magnetic force.

Replacing the Bed Plate Magnet

Over time, the magnetic strength of a bed plate magnet may diminish due to frequent exposure to heat or wear and tear. Replacing the magnet is a relatively simple task:

- Remove the Old Magnet: Gently peel off the old magnet from the print bed.

- Clean the Bed: After removing the old magnet, thoroughly clean the print bed to remove any adhesive residue.

- Install the New Magnet: Follow the installation steps mentioned above to secure the new bed plate magnet in place.

- Recalibrate the Bed: Always re-level the bed after replacing the magnet to ensure proper print adhesion.

Types of 3D Resin Printer Bed Plate Magnets

Below is a table listing various types of bed plate magnets used in 3D resin printers, including their material composition, advantages, and disadvantages:

| Material Name | Abbreviation | Model | Material Composition | Material Performance | Material Index | Material Advantages | Material Disadvantages |

|---|---|---|---|---|---|---|---|

| Neodymium Magnet | NdFeB | N/A | NdFeB (Neodymium Iron Boron) | High magnetic force, temperature resistance | N/A | Strong magnetism, long lifespan | Expensive, brittle |

| Ferrite Magnet | Fe3O4 | FERR | Iron Oxide (Fe3O4) | Moderate magnetic force, corrosion resistance | N/A | Cost-effective, durable | Weaker magnetic force, larger size |

| Samarium Cobalt | SmCo | SmCo-1 | SmCo (Samarium Cobalt) | High temperature tolerance, stable magnetic force | N/A | High stability, heat resistance | Expensive, hard to manufacture |

| Flexible Magnet | PVC | FLEX | PVC, Ferrite Powder | Moderate magnetic force, flexible design | N/A | Easy to handle, adaptable | Lower holding strength |

FAQ – Common Questions About 3D Resin Printer Bed Plate Magnets

Here are the 10 most frequently asked questions regarding 3D resin printer bed plate magnets:

1. What is the purpose of a 3D resin printer bed plate magnet?

- A bed plate magnet is designed to hold the printing surface securely in place, ensuring proper adhesion during the printing process and allowing for easy removal of prints once completed.

2. How do I know when to replace my bed plate magnet?

- Signs that your bed plate magnet needs replacement include reduced magnetic force, difficulty in adhering the print surface, or physical damage to the magnet.

3. Can I use a bed plate magnet on all types of 3D resin printers?

- Not all 3D resin printers are compatible with magnetic bed plates. Always check the specifications of your printer to ensure compatibility.

4. Are neodymium magnets the best choice for 3D resin printer bed plates?

- Neodymium magnets offer the strongest magnetic force, making them ideal for resin printing. However, they are more expensive and brittle compared to other types.

5. How do I clean a 3D resin printer bed plate magnet?

- Use a soft cloth or sponge with mild soap and water. Avoid abrasive cleaners to protect the magnet’s surface and coating.

6. Do magnetic bed plates affect print quality?

- A properly installed and functioning bed plate magnet will enhance print quality by providing stable adhesion, which can reduce warping or misalignment during printing.

7. Can I use a flexible magnetic plate for resin printing?

- Flexible magnetic plates are suitable for resin printing, especially in applications where you need easy removal of prints. However, they generally have a weaker magnetic force compared to rigid options.

8. What happens if the bed plate magnet gets too hot?

- Excessive heat can reduce the magnetic force of the magnet. It’s important to keep the temperature within the recommended range for your printer and material.

9. Are there any specific magnets for high-temperature 3D printing?

- Samarium-cobalt magnets are ideal for high-temperature environments due to their superior heat resistance.

10. Can I use a bed plate magnet on an FDM 3D printer?

- While magnetic bed plates are common in resin printers, some FDM printers may also use magnetic bed surfaces, especially if the print bed needs to be heated and leveled frequently.

Conclusion

Choosing the right bed plate magnet for your 3D resin printer is essential for ensuring consistent print quality and a smooth workflow. By understanding the various types of magnets, their technical parameters, and proper maintenance procedures, you can extend the life of your printer and achieve the best results. Whether you are a hobbyist or a professional in the field of 3D printing, this guide should provide you with the knowledge needed to make informed decisions regarding your equipment.

For those looking to get fast, reliable, and precise 3D prints, Great Light offers a range of services to meet your printing needs, from small to large batch processing.