01

Causes of deformation of the wire cutting part

Eliminate a medium bamboo and the bamboo leaf will run in half. Is that the material itself will have stress. The same goes for wire cutting treatment parts.

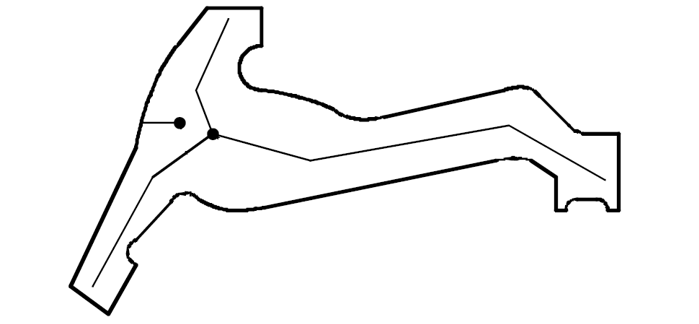

The deformation of the airline processing is linked to the structure of the part. The form of the narrow length of the concave mold and the convex mold is subject to deformation, and its deformation is linked to the complexity of the shape, length and ratio of width of the shape;

If the deformation is very low, in the precision range of treatment requirements, this deformation can almost ignore it. However, if the deformation exceeds the processing requirements of treatment, it will make size considerably deviated and will affect the form of treatment of the part.

There are many reasons for deformation, such as material problems, heat treatment problems, structural design problems, processes arrangement problems and the problem of selecting parts of the parts during the line cutting , etc. These many reasons will lead to the deformation of the internal stress of the material.

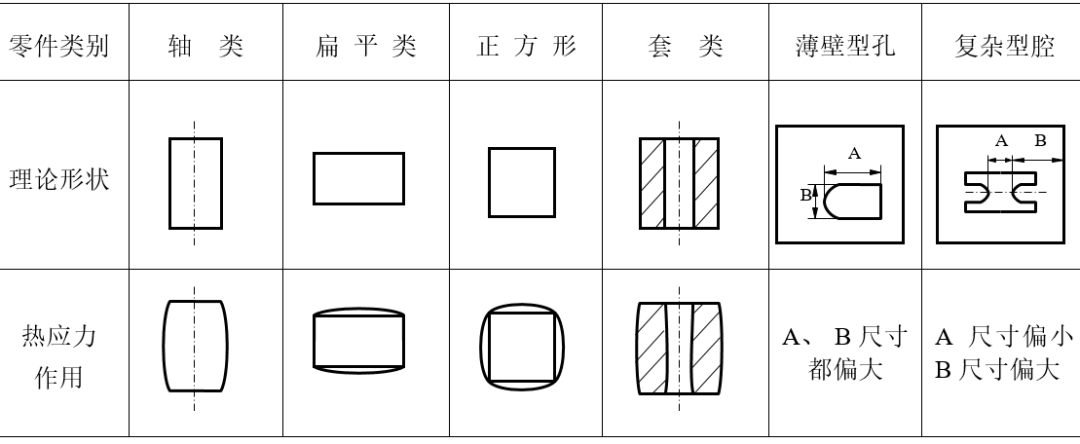

The effect of thermal stress on the shape of the part

02

Prevention measures for the treatment of parts deformation

Certain measurements may be taken to control the deformation of the treatment of the line cut to avoid the occurrence of deformation.

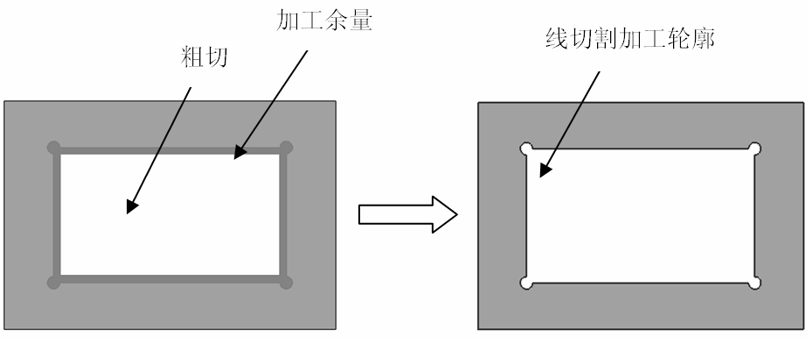

1) Cutting a gross machining or discharge before cutting

If a large cutting area is necessary, the relatively balanced state of internal residual stress inside the material will be damaged and the material will produce a large deformation. We can first eliminate most of the material stress, to perform rough treatment (rough treatment), eliminate the majority of balance first or reduce the path of the liberation constraint.

For large -scale concave models of cutting and treatment of electric flames, you can make two main cuts. Then use the standard to use the standard.

Roaring treatment of liberation stress reduces deformation

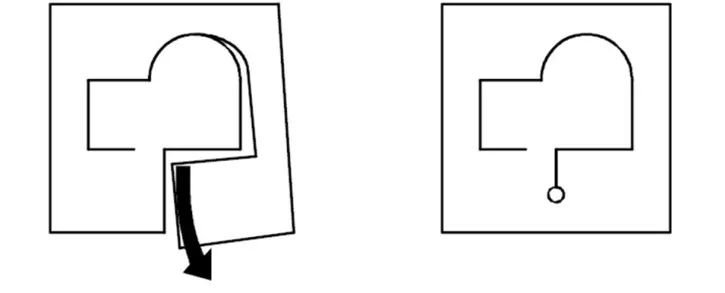

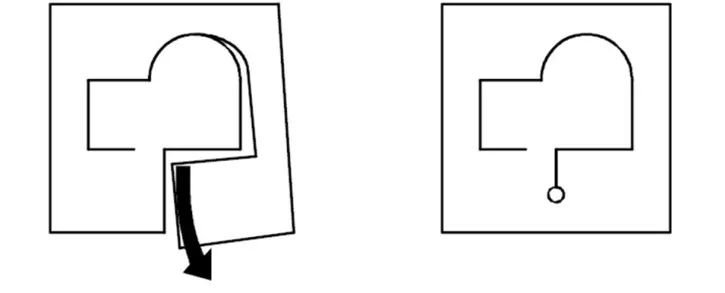

For the long narrow shape, first cut the stress path inside this hole, then treat the shape of the pores, as indicated in the figure below,

Release the constraint cup

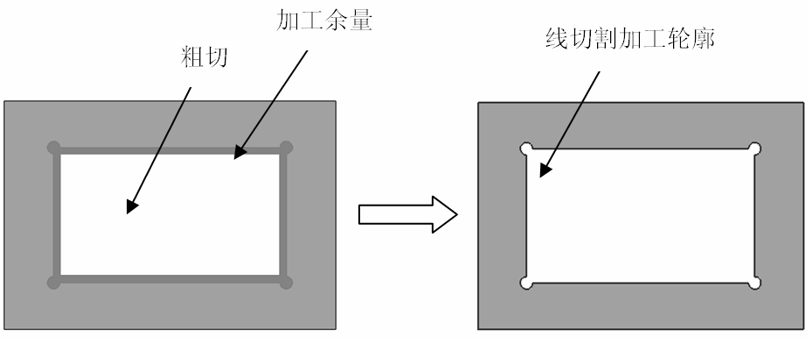

2) Treatment

When you cut the convex mold, if you do not treat the holes, cut it directly from the material, as shown in the figure below (A). Produce a deformation of the tensor or a deformation of the closed mouth. It can be treated on the material to penetrate the wire and perform a closed outline treatment. As indicated in the figure below (b), it can considerably reduce the deformation provided by the cutting and treatment of the electrical ceramics.

(A) Large deformed deformation (b) smaller deformation

Machining with silk holes to reduce deformation

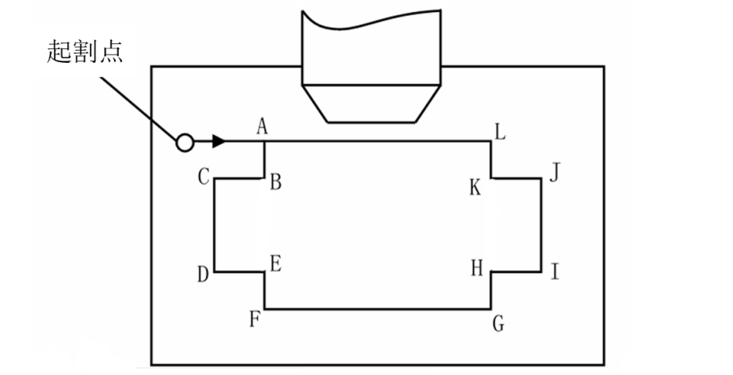

3) Optimize the processing path

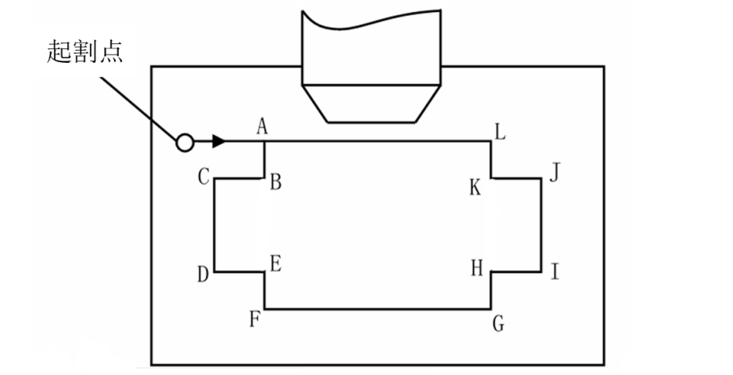

In normal circumstances, it is preferable to organize the treatment point at the point of maintenance near the clip and organize the section section of the part of the part of the separation part of the maintenance part at the end of Treatment path. At the end of the pliers. In certain treatments, due to the arrangement of unreasonable treatment paths, it is also the reason for deformation of the processing of the line cutting. As the figure below shows, the more reasonable processing path is: a → B → C → D … → A. If you follow the direction in the time direction: a → L → K → J … → A, cut the part and partially tighten the start of the cut. is directly tight by unreliable factors.

Arrangement of processing paths

4) Multiple cutting

Some parts still have a certain deformation after taking certain measures. Several cutting methods are used for rapid circuit cutting treatment, mainly for better surface roughness, but the use of multiple cutting methods has significant practical meaning to reduce the deformation of mold parts provided by the Stress problem.

5) Optimization of the process of treatment of the multiple holes model

During the online treatment of the models, with the effects of the original stress and the effects of the thermal stress generated by the cutting of the line, the irregular and irregular deformation will be produced, which will cause a cutting and restoration inequality subsequent and subsequent knife and treatment accuracy.

For this situation, models with high precision requirements are in multiple cutting treatment. Cut the waste of all types of holes for the first time. Take the waste → Take it → Cavity C Main, Take the waste → … → Mainly cut from the cavity n, take the waste → A cavity cut → B Poutive of the cavity → … → n Cavity n Caves, The treatment is complete.

This cutting method allows sufficient time to release the internal stress after the treatment of each type of holes, which can reduce the mutual impact caused by the various treatment orders and minimize trace deformation, and better ensure the size of Treatment of the precision of the model treatment of the model.

However, this process is large and large, and the workload is large, which is more suitable for machine-cutting machine tools with automatic wire. Once the cut was measured after cutting, the size of the shape meets the high precision requirements.

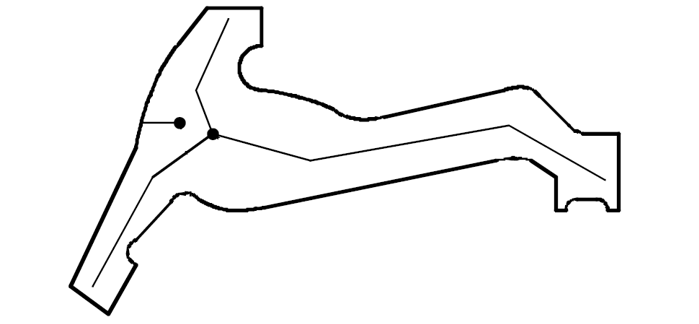

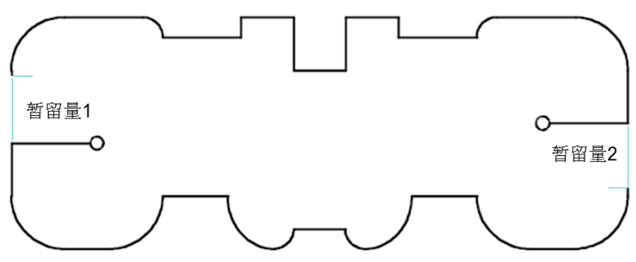

6) Define several sections of temporary retention

The treatment of large-scale and complex forms must be configured for two or more temporary retention, and several starting points must be defined, as indicated in the figure below. During programming, treat it in open shape.

Define several temporary retention sections

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.