In a horizontal machining center, as the tool rotates, the tool head can move radially along the end face of the tool holder. This type of tool that moves in the radial direction under the control of the CNC system is called a U-axis tool. U-axis tools can be used with horizontal machining centers to turn complex parts.

1. The machining center of Japan Ikegai Co., Ltd. has a U axis function:

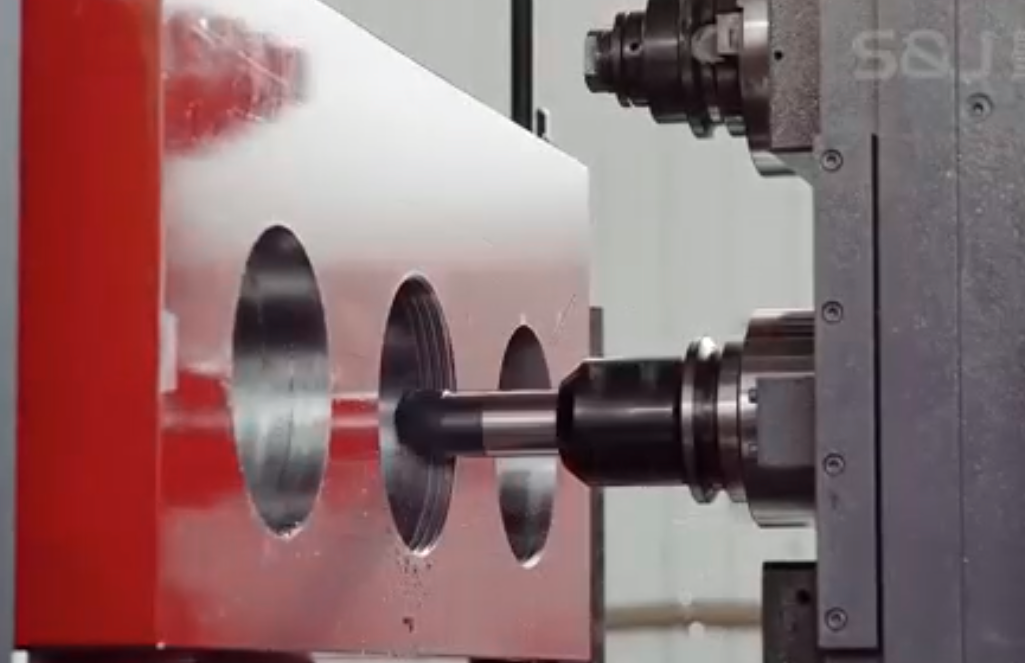

Ikegai’s U-axis cutter is the company’s patented technology (Japanese Patent No. 1432208), which means that while the cutter rotates, the cutter head can move radially along the end face of the tool holder. This type of tool which can achieve an accuracy of 0.001 mm under the control of a CNC system (Figure 1) and moves in the radial direction is called a U-axis tool.

The U-axis tool can be used with TV4 and TV5 vertical machining centers and TH500, TH600 and TH800 horizontal machining centers produced by Chibei to carry out turning of complex parts, such as cylindrical machining, l machining of internal holes, machining of end faces, machining of complex parts. axis All cutting tools can be processed: taper processing, radial processing, thread processing and groove processing, allowing the machining center to have turning functions.

The tool positioning accuracy on the U axis is ±3 (m) and the repeatability accuracy is ±1.5 (m; under the processing conditions of 1000 rpm speed and Feed rate 0.06mm/rev, it can process straight cylindrical and tapered parts. The roundness of the upper part can reach 2.3 (m), and the roundness of the tapered part can reach 2.6. (m).

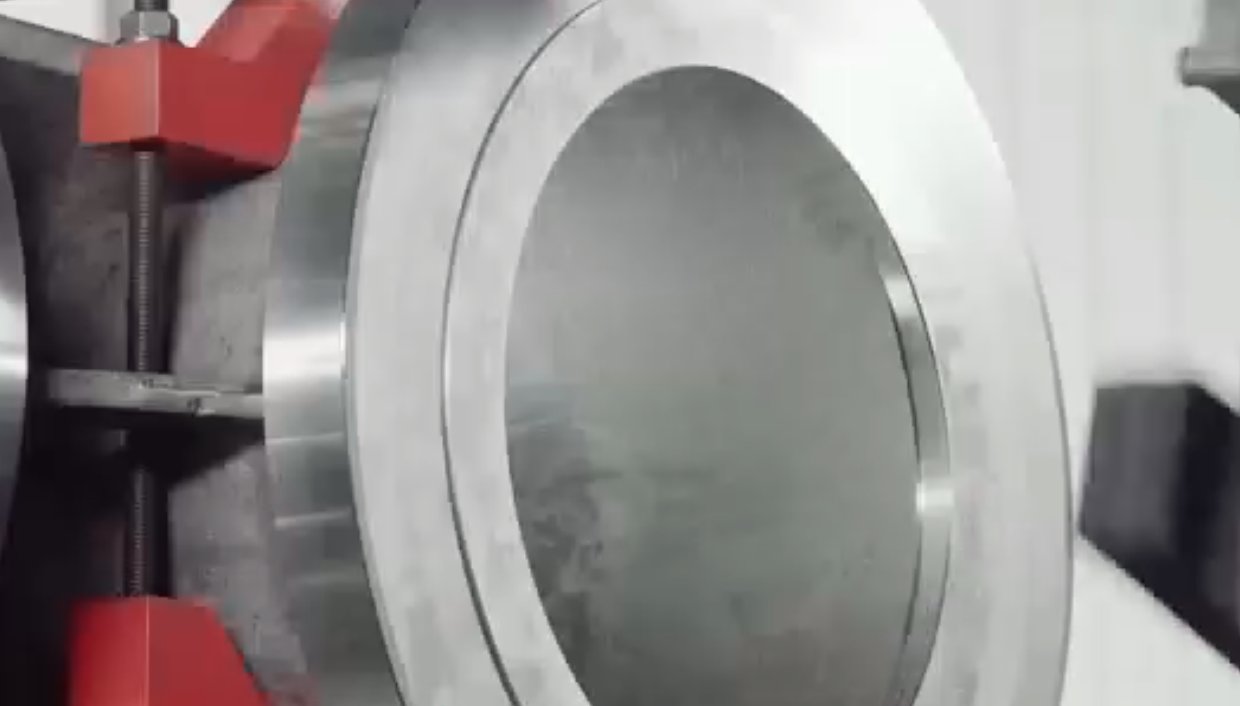

When processing a stepped hole like the one shown in Figure 2, a general machining center requires 6 forming knives to complete the process, but instead uses a U-axis tool, which only uses 2 knives (one ordinary drilling tool and one U-axis tool). tool). ) to complete processing.

Telephone number: 15910974236

2. Taiwan Jingyan horizontal machining center has U axis function:

The horizontal machining center with precision finishing is permanently equipped with a flat rotating disc. The U axis refers to the radial axis of the tool on the flat rotating disc, which can realize turning functions. All Jingyan horizontal machines can be equipped with a flat rotating disc with U-axis function.

Telephone number: 13501282025

3. Horizontal machining center with U-axis function from Niigata, Japan

Realizing the connection between U axis and Z axis, it can complete the processing of taper holes, R surfaces, threads, etc.

The main characteristics are:

1) The U axis unit is directly installed at the end of the spindle with high rigidity, and the driving unit is realized by gear and rack transmission inside the spindle, which Significantly improves U-axis stiffness;

2) The stroke of U axis is 50mm and the bore diameter can reach 300mm;

3) The tool holder is a 1/10 short taper double contact tool holder, suitable for high precision, powerful and heavy cutting;

4) Adopts U-axis cooling system that rotates synchronously with the U-axis to improve the cooling effect of the blade;

5) Equipped with special programming assistance software (SNAP3) to simplify and optimize program programming and debugging;

6) There is also an optional automatic detection and compensation system (without tool change in the machine), which automatically completes the whole process of rough machining → automatic hole diameter measurement → automatic hole compensation U axis → finishing machining.

Helpline: 18210062835

4. DS1200/450C from Trevisan Machine Tool in Italy(CNC horizontal machining center) equipped with CNC flat rotating disk (U axis) and W axis,

This is the greatest feature of this device! Telephone number: 13501282025

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.