Introduction to CNC machining

Manufacturing has undergone tremendous transformation over the past few decades, and CNC (computer numerical control) machining is at the forefront of this revolution. This high-precision technology is not only a boon to manufacturers; It serves industries ranging from aerospace to biomedical, automotive to electronics. In this comprehensive blog post, we’ll delve into the complexity of CNC machined parts, exploring its technology, processes, applications, and why its precision is indispensable in modern engineering.

What is CNC machining?

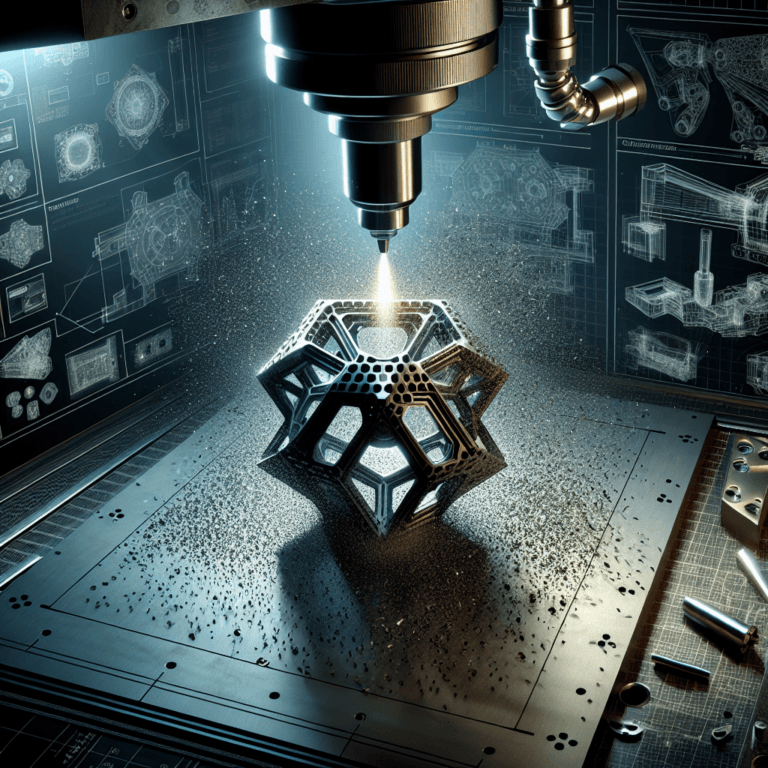

CNC machining is a subtractive manufacturing process, which means it involves removing material from a solid block or workpiece to shape it into the desired shape. This is achieved through the use of computer-controlled machines that operate cutting tools with extremely high precision.

Components of CNC machining:

CNC machine tools: This is a machine equipped with a CNC system that receives commands and converts them into motion.

Computer software: Software such as CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) are used to design parts and generate the commands required for CNC machine tools.

tool: The size, shape, and materials of the specialized cutting tools used can vary depending on the application.

- Artifact: The raw materials that CNC machines will process are usually in the form of blocks or sheets.

CNC machining encompasses a variety of methods, including milling, turning, drilling and electrical discharge machining (EDM), each with unique properties and applications.

CNC machining technology

Step 1: Design and Model

The first step in CNC machining is to use CAD software to create a detailed model of the part. This digital blueprint is critical to ensuring that specifications meet expected functionality, dimensions, and tolerances.

Step 2: CAM Programming

Once the design is complete, CAM software is used to convert the CAD model into G-code—a set of instructions that instruct the CNC machine tool on how to accurately carve the part from the raw material.

Step Three: Material Selection

Choosing the right material is critical to the functional and design requirements of a machined part. Common materials include metals such as aluminum, steel and titanium, as well as plastics and composites. Each material has unique properties that affect the machining process.

Step 4: Processing Setup

The workpiece must be firmly fixed on the CNC machine to ensure stability during the cutting process. Proper arrangement of clamping and fixtures is critical to minimizing vibration and achieving tolerances.

Step Five: Machining Operations

During this phase, the CNC machine executes the programmed G-code instructions. Cutting tools engage the workpiece to remove material in a precise manner, and a computer continuously monitors progress to ensure the original design is adhered to.

Step 6: Post-Processing and Finishing

After machining, parts often require post-processing including deburring, polishing, anodizing or coating to improve surface finish and functional properties.

Advantages of CNC machining parts

accurate: CNC machines operate with incredible precision, resulting in tight tolerances and consistent results.

Scalability: The same procedure can be used to produce multiple identical parts, making it easy to scale production.

Material efficiency: Because CNC machining is subtractive, it minimizes waste compared to other manufacturing methods.

Versatility: CNC technology can process a variety of materials and create complex designs for a variety of applications.

- Cost effectiveness: Although the upfront costs may be high, the efficiency and precision provided by CNC machining reduce long-term production costs.

Application of CNC machined parts

CNC machined parts are used in numerous fields, illustrating their adaptability and importance. Here are some of the key industries using CNC machining:

aerospace industry

In aerospace, weight is a key factor. CNC machining enables manufacturers to produce lightweight and durable aircraft components such as brackets, casings and structural parts that comply with strict safety regulations.

Automotive field

CNC machining is indispensable in the automotive industry. It is used to manufacture complex engine components, gears and custom parts that require high precision and durability.

medical equipment

Precision is critical in the medical field. CNC machining produces implants, surgical instruments and other specialized equipment that comply with strict health regulations while ensuring patient safety.

Electronic manufacturing

CNC machined parts play an important role in the production of housings, connectors, and circuit board assemblies for electronic devices. The precision of CNC machining ensures optimal functionality and reliability of these critical components.

Custom prototype

CNC machining is widely used to create prototypes. Its rapid production capabilities enable designers and engineers to quickly test new concepts before committing to large-scale manufacturing.

Challenges of CNC machining

Although CNC machining is praised for its advantages, companies may face certain challenges:

High initial investment: Setting up a CNC machining business can require significant initial capital, including the cost of machines, software, and tools.

Skilled labor demand: Skilled operators are essential to effectively program and run CNC machine tools, which can sometimes limit availability.

Material restrictions: Certain materials can pose challenges for CNC machining, such as those that are very hard or require special handling.

- Setup time: Although CNC machining is very efficient once set up, the time required to set up machine parameters for a new job can be lengthy.

Innovation in CNC machining technology

CNC machining is not static; innovation constantly shapes its future:

1. Integration of artificial intelligence and machine learning

Artificial intelligence (AI) is increasingly integrated into CNC systems to improve performance. Artificial intelligence algorithms can optimize cutting parameters and predict tool wear, increasing efficiency and reducing downtime.

2.Advanced materials

Developments in advanced materials, including composites and alloys, are expanding the scope of CNC machining, allowing the creation of lightweight yet strong parts with enhanced functionality.

3. 5-axis machining

5-axis CNC machining can achieve complex geometries in a single setup, significantly reducing lead times and labor costs.

4. Automation and Robotics

Automating CNC machining can streamline workflows, reduce human error, and further improve accuracy. The robotic arm can automatically load/unload workpieces and change tools.

5. Additive process

CNC machining is increasingly used in conjunction with additive manufacturing technologies, resulting in hybrid machines that can perform both functions in a single setup.

in conclusion

CNC machining is an integral part of modern manufacturing, providing unparalleled precision, efficiency and adaptability to numerous industries. Its ability to produce intricately designed, high-quality machined parts has made it a cornerstone technology in contemporary engineering. As advances in artificial intelligence, automation, and materials continue to shape the industry, CNC machining will undoubtedly continue to evolve and remain a key enabler of innovation in manufacturing processes.

Frequently Asked Questions (FAQ)

What is the difference between CNC machining and traditional machining?

CNC machining relies on computer control to perform precise cuts, while traditional machining involves manual operations that are often less precise and slower.

Is CNC machining suitable for small batch production?

Absolutely! CNC machining is ideal for both low- and high-volume production, making it ideal for prototyping and custom manufacturing.

What types of materials can be processed by CNC machining?

CNC machines can process a variety of materials, including metals (steel, aluminum, titanium), plastics, and composites.

Can CNC machines be used for both 2D and 3D parts?

Yes, CNC machines can produce both 2D and 3D parts, with 3D machining involving more complex operations and often requiring advanced technology.

How do I choose a CNC machine that suits my needs?

When choosing a CNC machine, consider factors such as the type of material you will be working with, the complexity of the parts you need to produce, your budget and available floor space.

In summary, CNC machining is at the forefront of manufacturing technology, providing incredible precision and versatility to a variety of industries. As innovation continues to reshape its landscape, understanding its nuances will enable businesses to fully leverage their potential for future growth and development.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.