To help everyoneRIGHTAdditive manufacturingCategorize paid software and free trial software.Organized by Mohou.comListing the Best Freebies for Every Stage of Your Workflow3D printing software. We’ve rounded up the best print and printer design, preparation, repair, viewing, and management software and their features.。

Although all software presented here is free, it should be noted that several programs may require additional (albeit inexpensive) hardware, such asRaspberry Pi. Additionally, please note that we exclude proprietary software and software that only works with a certain brand or model of printer.

We also added a coverof the 3D printing workflow to give beginners a better understanding of how each 3D printing software fits into the overall process, as programs and their place in the process chain can be confusing. If you are still in3DYou can start your printing journey by having a service provider print a part before investing in your own printer.

A,Cutting software

1、Treatment

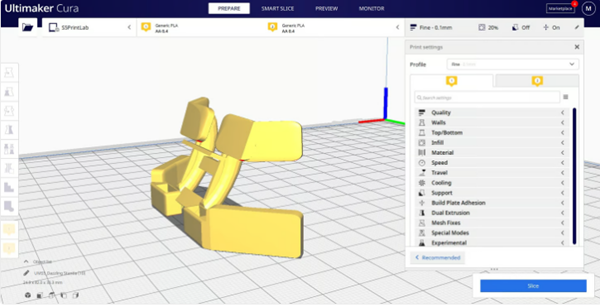

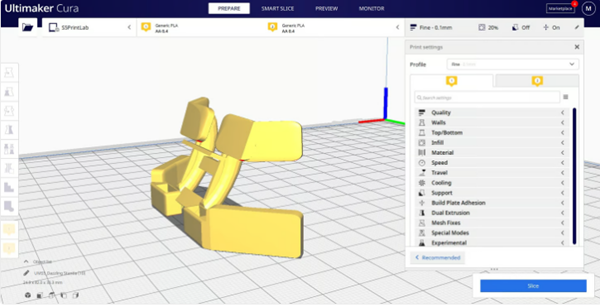

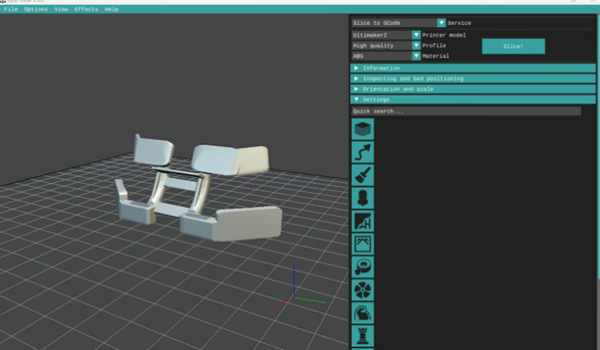

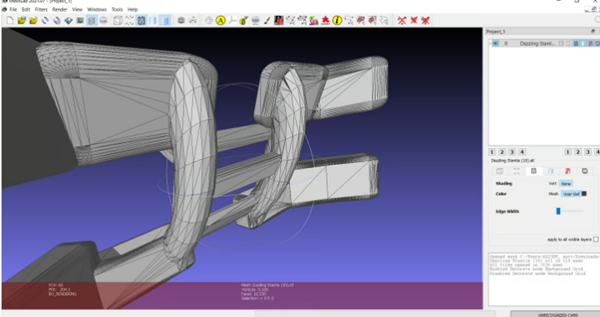

UltiMaker Cura cutting software (Source: All3DP)

Cura is open source slicing software developed by UltiMaker for its 3D printers, but it can also be considered a universal standard because it works easily with most other 3D printers. It can be expanded using a convenient plug-in system. As the most popular and most used in the market3D printingslicer, chances are this software already works for your3D printingThe machine comes with high-quality setup files, allowing you to start using it easily and immediately. If your printer profile is not available, you can easily download and import someone else’s profile.

This oneThe 3D printing software is easy to use and allows you to manage basic 3D printing settings on a clear interface. Starting in Basic mode, you can quickly get started and reconfigure the most basic printer quality settings. When you need finer control over print settings, switch to Advanced, Expert, or All mode for more settings. In these modes, Cura offers users up to 400 settings that can be adjusted as needed for optimal results.

This cutting software is constantly being updated and improved, with new versions released regularly, so you can be sure you have an up-to-date program. For example, their latest release includes a variable line width feature that promises to increase detail resolution, speed and intensity of prints.

You can also addCura is used as 3D printer host software to directly control your machine, but the 3D printer needs to be connected to a PC during the printing process. Seamless CAD integration with software such as SolidWorks and Siemens NX makes this software useful in professional applications as well. However, for most home users, Cura is simple and easy to use 3D printing slicing software.

2、PrusaSlicer

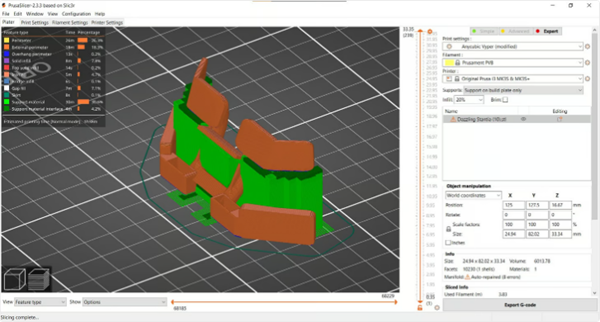

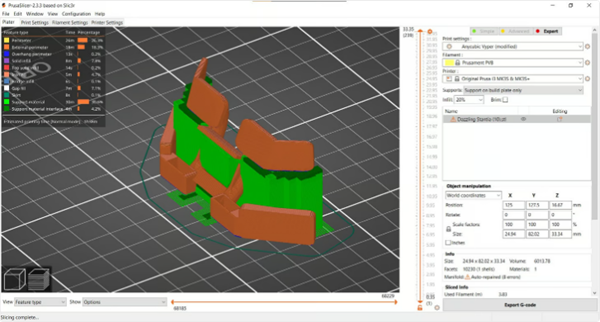

PrusaSlicer cutting software (Source: All3DP)

originalPrusa Research, the company behind the Prusa 3D printer, has created its own slicer, PrusaSlicer, based on a forked version of the open source slicer Slic3r. PrusaSlicer has quickly become popular with many people for several reasons: not only does it have a ton of adjustable settings like Slic3r, but it also has handy features not found in the original software.

With a redesigned interface,With native support for the Prusa printer line and convenient presets for commonly used materials, the software offers many improvements over the original. Some key features include customizable support structures, multi-material support, and variable and fluid layer height capabilities.

PrusaSlicer can be used to cut models for FDM and resin printers, and has several modes that allow you to change settings to suit your skill level, with “Expert” mode opening up a huge list of customizations. But don’t worry. Even simple configuration files work well in PrusaSlicer. PrusaSlicer has fewer printer presets than some other popular slicers, but it’s just as easy to adjust or import custom settings.

PrusaSlicer is derived from Slic3r, so it retains support for most of the original features and even accepts Slic3r configuration packages when importing configuration files.

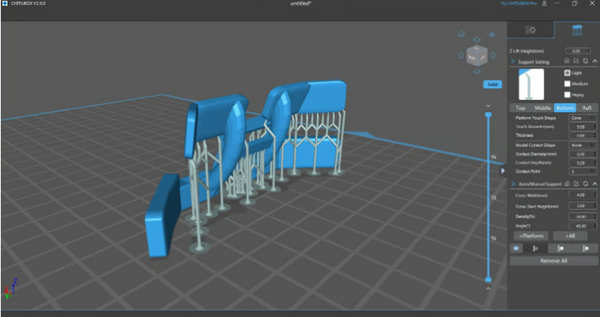

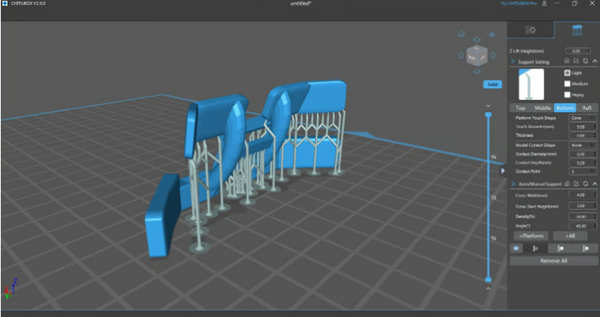

3、ChiTuBox Basic

ChiTuBox Basic LCD-based resin printing slicing software (Source: All3DP)

If you used Economical Desktop Resin3D printingmachine, it is likely that it hasChiTuBox (now ChiTuBox Basic). This software is developed by CTB Systems, a company that also makes many of the motherboards and firmware used in the printers mentioned above (so this company’s software is the default and works perfectly with any software).

The primary use of ChiTuBox Basic is to print 3D models on LCD resin 3D printers (also known as Mask Stereolithography or MSLA). Here you have extensive control over your printer’s curing settings and motion behavior, and you can choose from a long list of common and popular printers. Either way, your resin printer may have a copy stored on the memory card when it shipped from the factory.

A key part of preparing for resin printing is model orientation and support setup,ChiTuBox Basic covers both. Directional positioning is a bit basic – it doesn’t happen automatically – but automatic support generation is quite powerful and can provide good results in many situations. Additional adjustments may be required to properly support printing, but support for customization options is very intuitive.

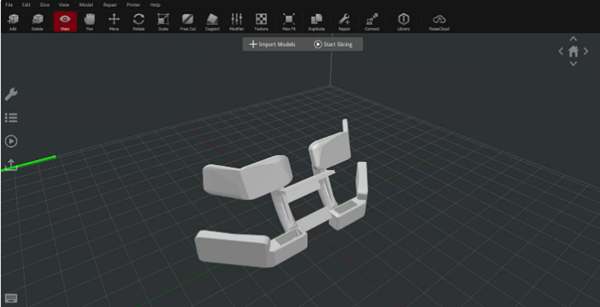

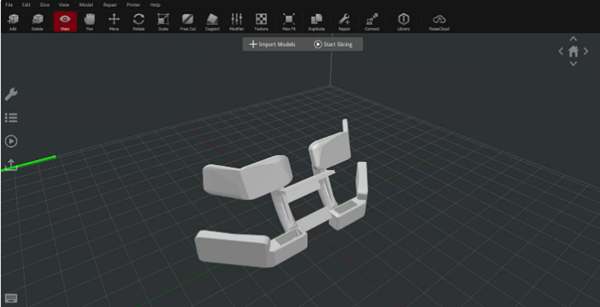

4、Creator of ideas

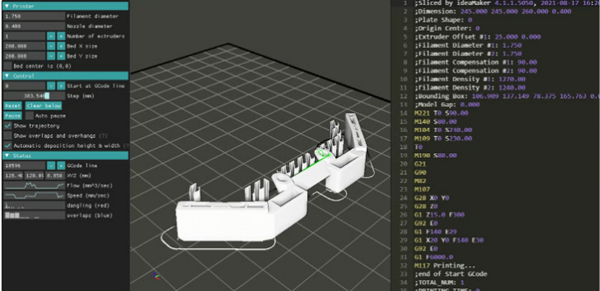

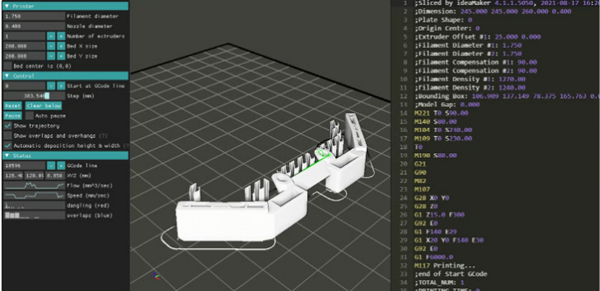

Raise3D ideaMaker slicing software (Source: All3DP)

Raise3D’s ideaMaker slicing software is optimized specifically for the company’s machines, just as PrusaSlicer was for the original Prusa printer and UltiMaker Cura was for UltiMaker hardware. But like other software, it also works well with third-party printers.

Its workflow and user interface are better thanCura and PrusaSlicer are slightly more complex, but with a little research you can quickly access detailed per-layer settings and print modifiers, including the ability to wrap textures on your prints to easily customize or mark up your parts.

AndOnce connected to Raise3D’s cloud service, you can download hundreds of community- and Raise3D-created printer and material profiles for faster, higher-quality printing, or create your own library of favorite settings and profiles.

Customizable support, model assembly to optimize large prints, and mesh repair toolsideaMaker becomes your daily life3D printingmultifunctional driver. print queue andOctoPrint’s native interoperability also comes with great additional quality of life features.

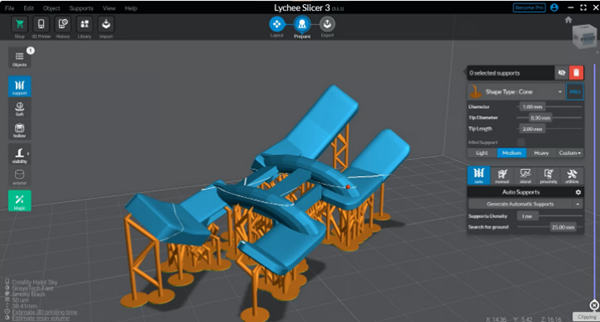

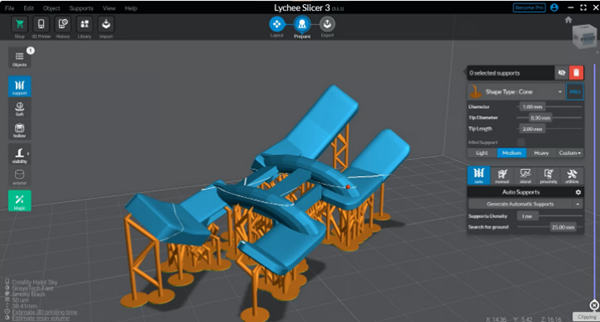

5、Lychee slicer

Lychee Slicer 3 LCD Resin Print Cutting Software (Source: All3DP)

ShouldThe slicer has a large number of3D printingmachine and resin profiles, this is a great third-party option for your resin slicing needs. Plus, it’s one of the smoothest, easiest-to-use, and most feature-rich experiences in desktop resin printing.

Automatic model positioning helps you start preparing the model, but you can skip everything and just click“Magic” button,hewill help you do everything. positioning, support…everything works. If you’re feeling lucky. The results can be mixed, but for simple objects we are happy to save time by not having to click through various model preparation dialogs.

The models can be manipulated, including hollowing out and cutting them, and there is a detailed print preview that can even be edited to show banana proportions. A charming3D cutting program.

Some options are not available to free Lychee Slicer users, but that doesn’t matter. The free version is fully functional and pretty good.

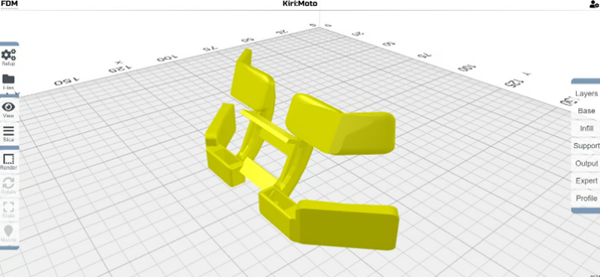

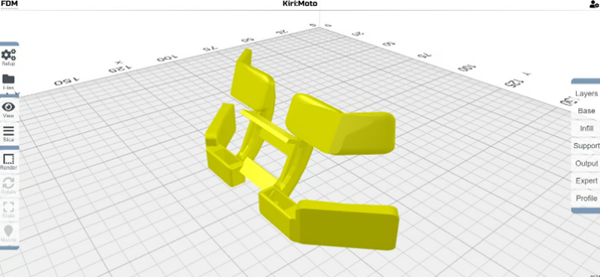

6、Kiri: Motorcycle

Kiri: Moto Web Slicer and G Code Generator (Source: All3DP)

If your computer’s hardware situation is a little shaky or you’re worried you might not have enough graphics power, browser-based softwareKiri:Moto may be a solution for you.

Written entirely to work in the browser, Kiri:Moto is a powerful tool you can use to3D printinglaser engraving or CNC routing to prepare the items (the common denominator here is that all items need to be exportedcode G). Kiri:Moto’s setup is more basic than natively installed slicers, but it also offers most of the commonly needed features, including zoom and z-jump settings.

Just use a few simple settings like build volume,G-code flavor and extruder number, you can add printers freely. On top of that, you can configure your printer and export a ready-to-print G-code file with all the necessary print settings.

7、GlaceSL

existCut the model in IceSL (Source: All3DP)

IceSL is an excellent 3D printing software. It is not only a 3D cutting software, but also a 3D modeling tool. In the left window, you can directly modify the model via a script based on the Lua language. This may seem intimidating at first, but it allows for intelligent parametric modeling.

Finally, you will find different trimming settings on the right. The novice-friendly pre-configured settings make slicing quick and easy, but expand the advanced settings and you’ll discoverVarious clever tricks developed by the IceSL team over the years.

Most notable in the previous version were the progressive variable settings, which allowed you to specify different values for specific print settings at specific layer heights,IceSL can make these changes independently. This means smooth transitions from dense fill to light fill, from fine layer height to coarse layer height, and so on.

two,Host and control

we are all tired of usingUSB drives and microSD cards transfer files to the 3D printer. But don’t worry, we have a solution: the host computer and control software.

1、OctoPrint

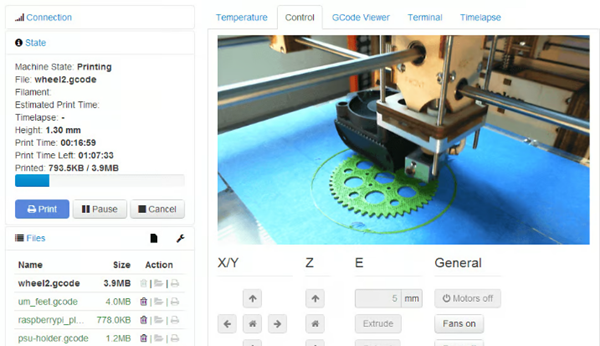

OctoPrint 3D Printer Host and Control Tools (Source: OctoPrint)

Designed by Gina Häußge, OctoPrint is a “pure” web-based 3D printer host that gives you full control over your 3D printer and print jobs. Simply connect a Wi-Fi enabled device, such as a Raspberry Pi, to the printer, and you can connect and control the machine remotely via OctoPrint’s web interface.

OctoPrint accepts G-code from almost any slicing software and includes a gCodeVisualizer to preview files before and during 3D printing. Additionally, you can slice STL files directly in OctoPrint and use them as an all-in-one print preparation package.

OctoPrint not only provides users with a host of tools to remotely control the printing process, but also offers several ways to track current print jobs. Users can configure OctoPrint to send push notifications or alerts sent to them through various messaging apps.

Perhaps more importantly,OctoPrint is free, open source, and has a thriving community. Easy-to-activate plugins extend OctoPrint’s functionality, making it a powerful solution for most 3D printing uses. In fact, the OctoPrint website has an extensive plugin library, providing easy access to innovative plugins created by a close-knit community.

If you wantBy freeing your 3D printer from the office and controlling it wirelessly, OctoPrint may be the best 3D printing software on the market.

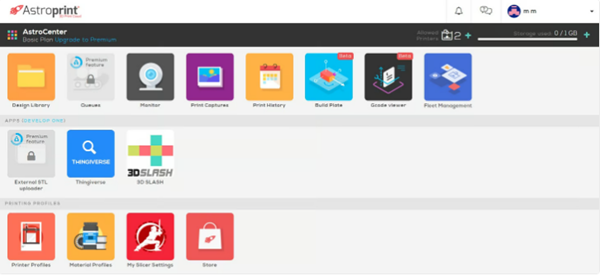

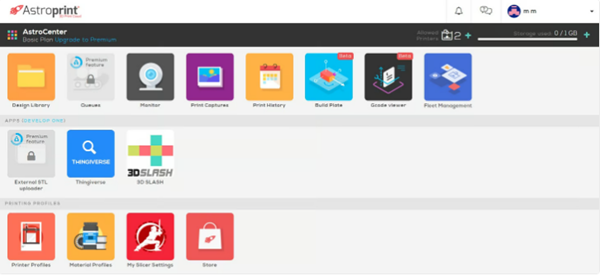

2、AstroPrint

Astroprint is a cloud-based printer management platform (Source: Astroprint)

AstroPrint is a cloud-based printer hosting solution that allows you to monitor and manage multiple 3D printers, store files, slice, and monitor analytics in the cloud. There are several paid account tiers, but the free tier is enough for you to easily manage one or more printers remotely.

AlthoughAstroPrint’s basic account is free, but if you don’t already have a Wi-Fi module on your printer, you’ll need to invest in hardware to connect the printer to the network, or if you have a Raspberry Pi spare (Raspberry Pi), use AstroBox to configure it as the machine’s wireless dongle. Like OctoPrint (in fact, OctoPrint also has an AstroPrint plugin to strengthen the connection), you can prepare and send print files to the machine via the web interface without the need for additional software.

AstroPrint is unique in its built-in compatibility with Thingiverse and MyMiniFactory, as well as free 3D CAD software like 3D Slash and Leopoly.

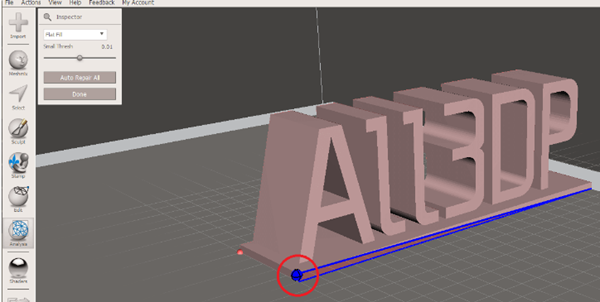

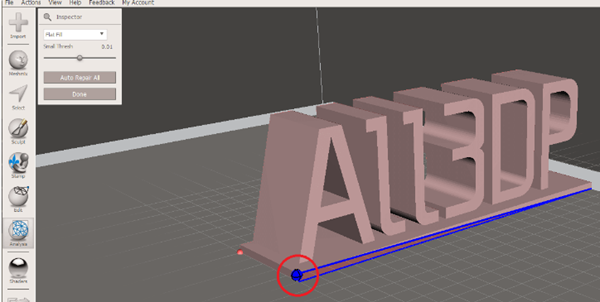

three,Edit and correctSTL file

Sometimes models don’t targetOptimized for 3D printing, where the model isn’t quite ready due to some quirks in the CAD software. In this case, editing and repair software will be at your side.

1、Mesh mixer

Meshmixer 3D model editing tool (Source: All3DP)

Meshmixer is a super advanced (free) Autodesk 3D printing software for viewing, inspecting, editing, designing and repairing STL files. It’s the perfect tool for discovering potential issues and fixing them automatically. For example, Meshmixer can highlight thin walls in STL files that could cause problems during the 3D printing process.

like a three-dimensional gridThe “Swiss army knife”, Meshmixer offers a host of features, including (but not limited to) drag-and-drop mesh blending, 3D sculpting and surface stamping, 3D patterns and meshes, hollowing , support structure branches, mesh smoothing, and more.

Whether you are repairing a 3D scan, preparing a model for printing, or designing multiple objects with specific dimensions,Meshmixer is a top-notch editing and repair tool suitable for various purposes.

2、Mesh Lab

MeshLab mesh editing tool (Source: All3DP)

MeshLab is an advanced open source STL editing software that provides tools for processing and editing 3D triangular meshes. This free program allows users to edit, clean, repair, inspect, render, convert meshes, merge models, and patch holes in 3D models.

The software is processingCAD software generates raw data and is ideal for preparing 3D models for printing. Its functions include 3D model reconstruction, color mapping and texture production, model visualization, etc. After a hiatus of almost 4 years, the software released a new version in 2020 and was last updated in February 2022. From this point of view, MeshLab deserves to replace Meshmixer, which is no longer supported . MeshLab is a reliable choice when you need to repair and clean unsightly 3D printed models with 3D printing software.

Four,Printable File Viewer

Sometimes it’s best to take a look at a file before running it into the printer, especially if it’s a download.Code G (not recommended). So here are some programs that can simply open these files and take a look.

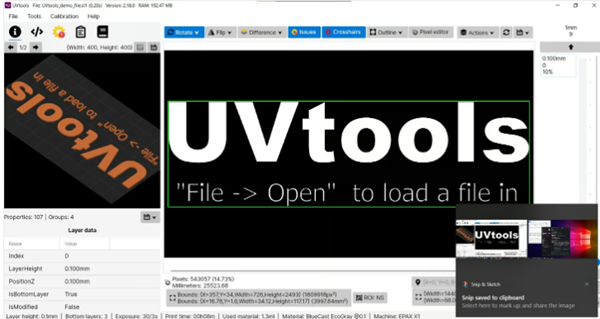

1、UVTools

UVTools General Resin File Analysis, Editing and Printing Toolkit (Source: All3DP)

UVTools is a standalone project that, in addition to being a powerful file viewing and layer editing and repair tool for mask stereolithography, can connect to PrusaSlicer, add a long list of third-party MSLA printer profiles popular. These configuration files are definitely not those of the Prusa machine. (Here PrusaSlicer only allows you to choose two original Prusa SL1 machines for resin printing).

latest versionUVTools supports Two-Stage Motor Control (TSMC), a feature we’ve been seeing a lot of lately (ChiTuBox Basic also added this feature in the latest update), which allows for staggered print speeds for different parts of the movement of each layer, thereby increasing your chances of successful printing and reducing overall printing time.

In addition to the above functions,UVTools also has the ability to create your own resin layer cure time calibration prints, which can be used to test new resins and find suitable settings for different layer heights. A universal resin printing toolbox. very useful

2、Web Printer

based onG-code viewer for WebPrinter browser (Source: All3DP)

WebPrinter is a simple browser-based G-code previewer tool developed by IceSL to quickly check the mysterious G-code files you found on your long-forgotten SD card. It’s much faster than launching a fully functional slicer and clicking on a bunch of “updates available” messages.

Click the link to downloadG-code file, you will see WebPrinter start, displaying the tool path that the file will instruct the printer to follow. It would be nice to see a real-time view of the temperature settings – unfortunately this functionality is not available in the diagnostics that run during the simulation – but as a quick and dirty check of potential printouts, it works quite well.

3、Gcode analyzer

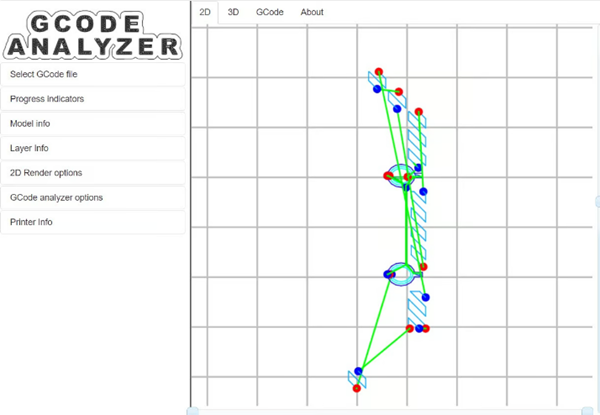

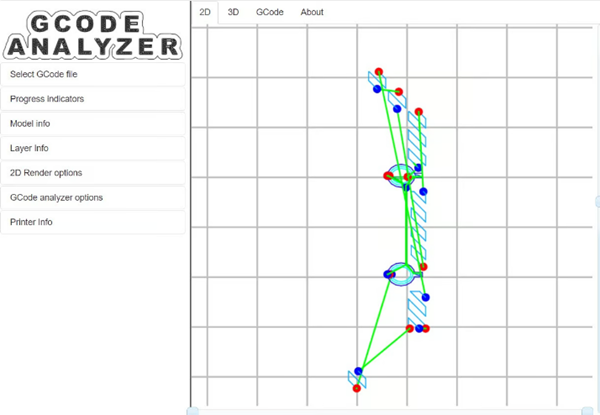

Browser-based G Code Viewer GCode Analyzer (Source: All3DP)

functionality

Gcode Analyzer has been around almost as long as desktop 3D printing itself, but still going from strength to strength, it’s a very simple and useful web tool for analyzing, you guessed it, G-code.

Although the three-dimensional simulation is somewhat incomplete, we only simulate the two-dimensional simulation andInterested in the G code view. In 2D view you can see the different layers of your print very clearly. Two sliders allow you to switch between layers and display the toolpath movement in sequence. In the G-code view you can see the entire text of the file and thus visualize the individual instructions for the printer.

Before exporting, you can see in the slicer previewG-code commands, while lightweight, streamlined tools like Gcode Analyzer make it easy to view old print files to see exactly how the nozzle ran across the part.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.