Unlocking Efficiency: A Comprehensive System Solution for Mitsubishi CNC Data Acquisition and Mooring at the MES Platform

In the realm of manufacturing, the integration of cutting-edge technology is paramount for maximizing efficiency, productivity, and precision. One pivotal aspect of this integration is the acquisition and management of data from CNC (Computer Numerical Control) machines. Mitsubishi, a leader in CNC technology, offers a robust platform for data acquisition that can be further enhanced and streamlined when integrated with a Manufacturing Execution System (MES). This blog post delves into the creation of a comprehensive system solution that combines Mitsubishi CNC data acquisition with mooring at the MES platform, aiming to elevate manufacturing operations to unprecedented levels of sophistication and performance.

Understanding Mitsubishi CNC Data Acquisition

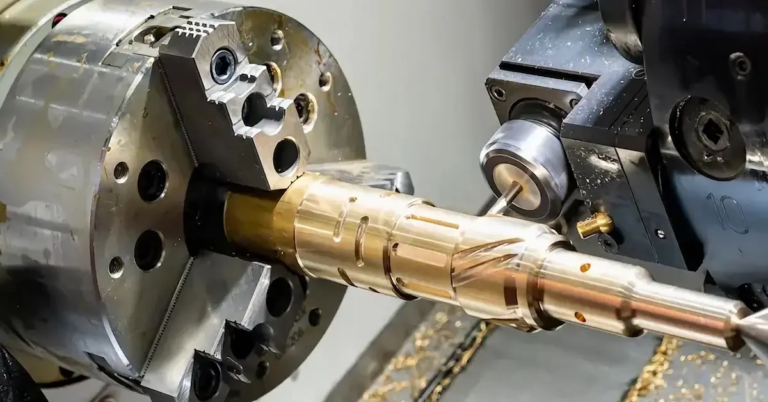

Mitsubishi CNC machines are renowned for their high precision and productivity. These machines generate vast amounts of data during operation, including production volumes, downtime, and error messages. The acquisition of this data is crucial for ensuring that manufacturing processes are optimized. By leveraging Mitsubishi’s CNC data acquisition capabilities, manufacturers can gain real-time insights into their production lines, identify bottlenecks, and make informed decisions to enhance overall efficiency.

The Role of MES in Manufacturing

A Manufacturing Execution System (MES) is a software system that tracks and manages the production process in real-time. MES provides the bridge between the factory floor and the enterprise systems, offering a holistic view of production operations. By mooring Mitsubishi CNC data acquisition at the MES platform, manufacturers can integrate machine-level data with broader production and business information. This integration enables comprehensive oversight, allowing for better management of inventory, quality control, and supply chain operations.

System Solution Architecture

The proposed system solution involves several key components and stages:

- Data Collection: Mitsubishi CNC machines are equipped with interfaces that allow for the real-time collection of operational data. This data is then transmitted to a centralized server or cloud platform.

- Data Processing and Analysis: Utilizing advanced analytics tools, the collected data is processed and analyzed to provide insights into production performance, machine health, and product quality.

- Integration with MES: The processed data is then integrated into the MES platform. This integration enables the synchronization of production scheduling, inventory management, and quality control processes with real-time machine performance data.

- Visualization and Reporting: The MES platform provides a user-friendly interface for operators and managers to view real-time production data, receive alerts on potential issues, and generate detailed reports for performance evaluation.

Innovations and Advantages

The integration of Mitsubishi CNC data acquisition with an MES platform introduces several innovations and advantages:

- Real-Time Monitoring: Enables immediate identification of production issues, allowing for prompt intervention and minimizing downtime.

- Data-Driven Decision Making: Provides a robust data foundation for making strategic decisions about production planning, resource allocation, and quality control.

- Enhanced Efficiency: Automates many manual data collection and analysis tasks, freeing up staff for more strategic and high-value activities.

- Improved Quality Control: Facilitates the implementation of proactive quality management strategies, reducing the likelihood of defects and improving overall product quality.

Implementation and Support

Implementing such a system solution requires careful planning, execution, and ongoing support. Key considerations include:

- Technical Compatibility: Ensuring that Mitsubishi CNC machines and the MES platform are technically compatible and can communicate seamlessly.

- Training and Education: Providing comprehensive training to operators and management on the use and benefits of the integrated system.

- Maintenance and Updates: Regularly updating software and performing maintenance to ensure the system remains secure, efficient, and aligned with evolving manufacturing needs.

Conclusion

Combining Mitsubishi CNC data acquisition with mooring at the MES platform presents a powerful system solution for manufacturing organizations seeking to elevate their operational efficiency, product quality, and competitiveness. By embracing this integrated approach, manufacturers can harness the full potential of their CNC machines and MES systems, paving the way for a future of smart, agile, and highly productive manufacturing. As the manufacturing landscape continues to evolve, the adoption of such innovative solutions will become increasingly critical for staying ahead in the industry.