TREEfat3D printing is praised for its ability to produce parts with intricate details and smooth surfaces. Stereolithography (SLA) and its sister technologies, masked stereolithography (MSLA/LCD) and digital light processing (DLP) were initially favored for aesthetics and prototyping, proving that resins are not only beautiful to look at but also powerful.

The basic principle of these three technologies is to use light to solidify liquid resin layer by layer, but their light sources and projection methods are different.SLA uses lasers to track the shape of an object, which is more precise but often slower, while DLP uses digital projectors to flash a single image from each layer, which is faster but can sacrifice some resolution. Similar to DLP, LCD uses the LCD screen to block light, providing a balance between speed and resolution.

Many resins are compatible with all three technologies, although some may be specifically formulated for one or the other due to differences in curing wavelength or light intensity.

But what intensity? Traditionally, resin3D printing is considered somewhat fragile compared to fused deposition modeling (FDM) printing. However, recent developments in resin formulations have paved the way for a new generation of strong, durable resins that rival and, in some cases, surpass specialty yarns in terms of strength.

In this article, Mohou.com will share with youDive deeper into the world of high-strength resins to learn about their properties, the factors that influence their performance, and the different applications where their strength really comes into play. Whether you’re an engineer, designer, hobbyist, or simply interested inCurious about the latest advances in 3D printing, you will be amazed by the extraordinary strength and versatility of modern resin 3D printing.

Quantity determines potency

picture1:Elegoo’s ABS-like resin offers strength and detail capabilities (Source: Shib_Mc_Ne via Reddit)

talk aboutWhen considering the strength of 3D printing resins, it is important to know that “strength” is not just a word. It includes several ways in which a material resists breaking or deformation under the action of different forces. Here are the main strength properties of resin 3D printing:

tensile strength:This is the ability of the resin to resist breakage. Think about stretching a rubber band: tensile strength is how much force it can withstand before breaking. The higher the tensile strength, the less likely the resin will break when pulled.

Bending resistance:This is a measure of the resin’s ability to resist bending. Think of a plastic ruler that bends under pressure; flexural strength refers to how much force it can withstand before cracking or bending permanently.

Shock resistance:This tells us how well the resin can withstand sudden impact or impact without cracking. It’s like the difference between a phone case that cracks after a drop and one that can withstand multiple drops.

Compressive strength:The opposite of tensile strength. It measures the compressive force a resin can withstand before warping or collapsing.

Shear resistance:It is a measure of a material’s ability to resist opposing forces on a flat surface. Imagine that you are cutting a fruit with a knife; Shear strength refers to the force needed to cut the fruit, and some fruits are more difficult to cut than others.

Next, we will look at the different types of resins associated withComparison of FDM materials.

Resin andFDM

picture2:FDM (left) and resin (right) prints differ in appearance and other aspects (Source: DCA_Tabletop via Reddit)

Compare the resin andFDM is not a simple apples-to-apples comparison. The strength of FDM parts can vary greatly depending on factors such as infill percentage and pattern, layer height, and the filament itself. However, we can make some general comparisons based on resin type. These resins can be standard (not intended for a specific application), heavy duty (formulated with additives) and high performance (with greater strength, elasticity, chemical resistance, etc.).

tensile strength

Standard resin: approx.PLA (40-50 MPa) is comparable to some PETG blends (40-60 MPa).

Resistant resin: more efficient than the standardPLA and PETG, and sometimes even up to the higher strength of ABS (up to 70 MPa).

High performance resins: easily outperform the most commonThe tensile strength of FDM filaments in some cases reaches 90 MPa.

Bending resistance

Standard resin: withPLA is similar (around 50-60 MPa).

Resistant resin: generally more resistant thanPLA and PETG are much stronger, sometimes even exceeding ABS (up to 100 MPa).

High performance resin: bending resistance far exceeds ordinaryThe bending strength of FDM filaments even exceeds, for some, 130 MPa.

Shock resistance

Standard resin: generallyFDM filaments are more fragile, but this can vary significantly between different resins.

Durable resin: designed to absorb shock, often meeting or exceeding strengthImpact resistance of the PLA or ABS mixture.

High Performance Resins: Variations vary widely, with some prioritizing other properties over impact resistance.

This general comparison of technologies gives us a broader overview of the benefits of different processes and materials, then let’s take a closer look at other factors that influence resin printing.

not just materials

picture3:Support also plays a role (Source:All 3DP)

The strength of a 3D printed part isn’t just determined by the resin you use. Other factors can also have a significant impact on the strength of a component.

stress concentration

Although the resin is the same in all directions, the shape of the part can create stress points at corners or sharp edges. These stress points can be weak points, and the way components are placed affects how these weak points relate to the applied forces.

support structure

Support structures are essential for successful printing with resin, but they can create stress points and potential weak areas in the final print. How parts are positioned during printing will affect the location and number of supports required, thus indirectly affecting the overall strength of the printed object.

post-processing

picture4:There are different post-processing stages (source:All 3DP)

Post-processing is resinAn important step in 3D printing that affects the final strength and functionality of the part. Proper post-processing helps your prints achieve optimal mechanical properties while still looking great.

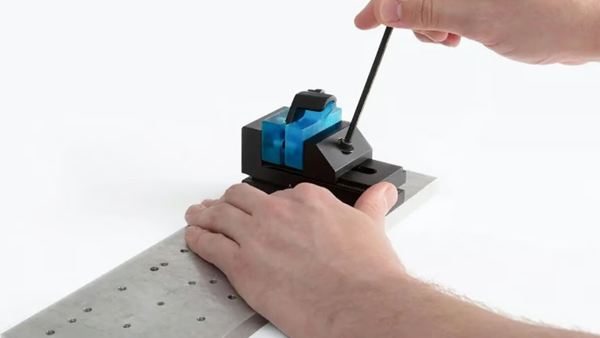

Remove media

The first step is to remove the supports. These temporary structures are necessary to support overhangs and complex shapes during the printing process, but they must be carefully removed after printing. You can carefully separate them using a tool such as flat-nose pliers or pliers. If the supports are not properly removed, they can leave stress points or small cracks in the surface, weakening the structure. For optimal strength, remove supports after curing, as cured prints are stiffer and less likely to be damaged during this stage.

washing

The next step is cleaning. This means cleaning the print to remove any uncured resin (liquid) on the surface or in internal cavities, and depending on the type of resin there are different considerations to take into account. Isopropyl alcohol is generally used.(IPA) for cleaning, but tripropylene glycol monomethyl ether (TPM) is gaining popularity as a safer alternative. Whether you immerse your print in a solvent bath, use a spray bottle, or a dedicated cleaning station, the goal is to remove uncured resin. Cleaning prevents surface stickiness and improves the mechanical properties of your prints.

solidify

The final stage is hardening. This involves exposing the print to UV light, causing a chemical reaction called cross-linking. This reaction bonds the polymer chains of the resin together, solidifying the material and increasing its strength. Proper curing is important to achieve the full strength, hardness and other properties of the resin. UV lamps and specialized resin curing stations are often used for this purpose.

Different resins may require specific wavelengths of UV light, so it is important to use a lamp that emits the correct spectrum. Curing time varies depending on resin type, light intensity and print thickness. Adequate curing is essential; under-curing can make the resin soft and brittle, while over-curing can make the resin brittle.

design considerations

picture5:The design of the 3D model greatly affects the strength of the final print.

Here are some important things to consider:

wall thickness

The thicker the wall, the stronger the part because the thicker the wall, the more resistant the material is to breakage and deformation. However, the thicker the wall, the longer the printing time and the more material used. For most resin prints, it is recommended that the wall thickness be at least1-2mm to ensure part strength while balancing material usage and printing time.

geometry

Sharp corners and edges create stress points that make parts more likely to break. The use of fillets (rounded corners) distributes stresses more evenly and increases the strength of the part. For unsupported walls, ensure the thickness is at least1mm and use a rounded base to reduce stress at the joints and prevent warping or falling off during printing.

Holes and drainage holes

Making a hollow resin print can save material and reduce weight, but drainage holes should be left to prevent uncured resin from getting stuck inside. Trapped resin can cause a pressure imbalance, potentially leading to cracking or failure. The wall thickness of hollow prints should be at least2 mm to maintain resistance.

application

picture6:The durable resin has proven useful in many situations (source:form laboratories)

The superior strength of modern resins is not just theoretical; it creates exciting new possibilities in a variety of fields. Here are some real-world examples of how resistant resins can change3D printing applications:

functional prototype

The tough resin is useful for making functional prototypes, allowing engineers and designers to create parts that can withstand real-world testing. For example, the automobile industry usesFormlabs Tough 2000 resin and other resins are used to 3D print complex snap mechanisms, hinges, and other functional parts. These prototypes can withstand repeated use, stress and shock, and can provide valuable feedback on designs before committing to expensive mass production tooling.

end use parts

Some resins are now strong enough not only to make prototypes, but also to make final parts. For example, in manufacturing, jigs and fixtures (tools used to hold and position parts during assembly or machining) are made with durable resins.3D printing. These printed tools can withstand daily wear and tear, providing a cost-effective and customizable alternative to traditional manufacturing methods.

creative apps

The strength of resin opens up new possibilities for artists and amateurs. For example, resin jewelry designers can now create intricate, delicate pieces that are less likely to break. Thanks to the increased strength of tough resin, it is now possible to reliably produce delicate filigree designs, thin walls and complex shapes that were once too fragile for resin. In addition, the resin3D printing features smooth finishes and a variety of colors for beautiful and durable artistic creations. Beautiful miniatures enhance the gaming experience.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.