Testing on animals for medical purposes raises many questions, particularly on an ethical level. In France it is a regulated practice and the figures decrease from year to year— In 2022, just over 1.8 million animals will be used, a decrease of 4% compared to 2021. One of the reasons for this decline could be due to the frequent use of additive manufacturing. Either way, that’s what a team of scientists from the Henry Rice Institute is trying to do. They use 3D printed bone structures to study different forms of cancer. The objective is to observe how cancer cells evolve in an environment similar to bone tissue. This means that animal testing is significantly reduced and researchers can speed up and increase the number of tests. A democratizing approach?

This is obviously not the first time that we have addressed this subject, in the medical field,3D technology is often used to carry out tests and better understand certain pathologies. They allow custom structures to be created from different materials, making it easier to grow a variety of cells. Furthermore, these projects were designed according to local needs and conditions, presumably within a very short time frame. We clearly understand the advantages of additive manufacturing in these situations: the work of the Henry Rice Institute is another example.

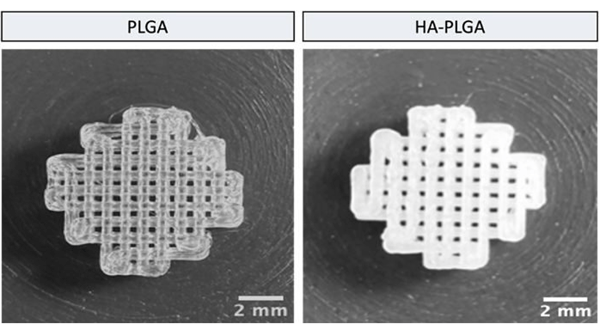

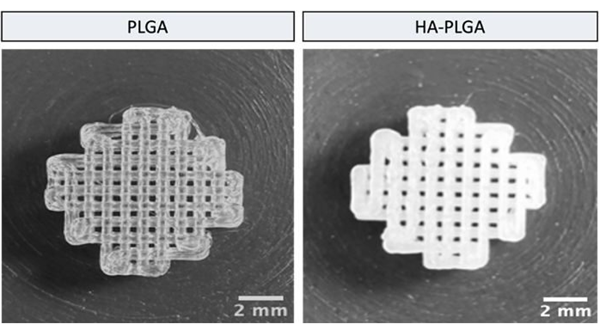

3D printed bone structure (Photo credit: Fatih Eroglu)

More specifically, the team is working on3D printed bone structure which will serve as a “house” for cancer cells, particularly those of the breast. The objective is to study how they spread in organizations. To do this, they use two materials: PLGA and HA-PLGA. The first is a biodegradable polymer which forms the basis of the bone model. As for the second, it is a mixture of PLGA and hydroxyapatite, naturally present in bones. This makes the model more realistic and creates an environment closer to natural bone tissue.

The preferred technology for this work is molten material deposition, which allows the team to significantly reduce costs. According to her,The 3D printer costs less than 1,000 euros, whereas if she had chosen a 3D bioprinter, it would have cost her thousands of euros. In fact, they are 3D printed scaffolds used to facilitate cell culture to understand the proliferation of cancer cells. Specifically, the researchers placed inside stem cells called mesenchymal stem cells from bone marrow, which can transform into any cell they want. One of the scientists, Fatih Eroglu, added: “It’s like giving these cells the perfect environment to become what we want them to be. Our preliminary results show that not only are these cells able to survive, but they also create a true skeletal environment. , we can use it to study cancer metastasis.

The first test gave positive results. In fact, the cells successfully attached to the scaffold, grew and multiplied. Their conversion into bone cells allows scientists to study how cancer cells interact with bone tissue. Alternatives to animal testing that are intended to be more ethical.

Fatih Eroglu concluded: “We’re not just building scaffolds, we’re creating new ways to study diseases and test treatments, reducing animal testing while accelerating research progress. »

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.