It turns out that using a granular formPLAto drive3DPrinting is better than using filamentsPLAPrinting is cheaper and faster, but to date there is no reliable comparative study of the resulting parts.

A new study just published in the journal Additive Manufacturing, funded by the European Space Agency, compares pellet printed products3DThe strength and overall quality of printed parts compared to those printed with filament.

The filaments are made from plastic pellets (source:Flexible hose)

“The results show that the extrusion of filamentous materials(FME)and extrusion of granular materials(GME)There were no significant differences in the mechanical properties of the printed parts in terms of tensile properties, flexural strength and modulus, and impact resistance.(>0.05),»Extrusion of particle-based materials in printingPLAAuthor of Mechanical Properties of Parts Comparable to Extrusion of Filament-Based Materials: A Comprehensive InvestigationHandai LiuOthers have expressed.

TumakerAlthough not used in this study, it is a desktop-sized tool.FDMPrinters that can use materials in granular form

(source:Tumaker)

Liuwrote,“Previous studies have reported mixed results, with some concluding thatGMEMechanical property report of printed partsFMEThe printed parts are of poor quality, while other studies report equivalent or slightly better performance.»But he said these studies“Limited to the evaluation of traction or flexion performance»,And“lack of clear explanations to support them»。

Liu’s comparative testing took a more detailed approach, including tensile testing, impact testing, three-point bending testing, and hardness testing to reveal the full mechanical properties of printed parts. In addition, his team used scanning electron microscopy(SEM)differential scanning calorimetry(DSC)thermography, rheological testing and gel permeation chromatography(GPC)Perform a parts analysis.

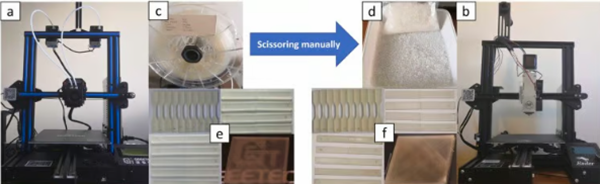

FME(a)AndGME(b)printer,FME(c)AndGME(d)raw material,FME(e)AndGME(f)Preview Print Example (Source: Particle Based Materials Extrusion)

Pellets and threadsPLAPrint comparison

This study used data from the NetherlandsWateringofReal filamentdiameter1.75mm polylactic acid(PLA)Filament. As granular material use the same filament, just cut it with scissors1 to 2.5millimeters of fragments. The printer isCreality Ender 3 Proready to use right out of the box, comes with filament, then useMahorextrusion head for granular materials andNo. 17A stepper motor was modified to drive a single screw extruder.

Most print settings were set to the same values for both printing methods, except for extrusion speed and print speed.

According to new research, you can expect to use a granular formPLAto drive3DPrinting and using as filamentPLAto drive3DPrint with the same print quality

(source:Mahor)

different:

Although the pieces compared are similar in almost every way, Liu found some points of comparison.

The average molecular weight of the pellet-printed samples was higher than that of the filament-printed samples, which can be attributed to the lower actual temperature of the pellet extrusion chamber because“Different location between heater, thermistor and melting chamber compared to filament extrusion»head,»The study says.

This is why the results on the mechanical properties (tensile strength, flexural strength and impact resistance) of the granular samples are slightly higher than those of the filament samples. The report explains:“The higher the molecular weight, the better the tensile, flexural and impact properties, because the greater the degree of entanglement of the polymer chains in the amorphous regions of the polymer, the greater the resistance to movement.»

The average hardness value of the particle prints was slightly lower than that of the filament samples, which can be attributed to their rougher surface and slightly lower density, the report said. Average Particle Shore ADThe value is81.44the average Shaw of the filamentDThe value is82.28。

Mahor V4Pellet extruders are among the few available for desktop useFDMOne of the pellet extruders complementary to the printer (source:Mahor)

LiuIt was concluded that due to comparable mechanical properties, the use of granular materials3DPrinting eliminates the filament manufacturing step, saving time and money.

Although the study did not evaluate printing using recycled materials or scraps, it inferred that particle printing“Ability to recycle thermoplastic waste and print heat-sensitive materials directly in pellet form»,Thus“Save costs, reduce environmental impact and increase efficiency»and simplified3DPrint workflow.»

Source: ALL3D

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.