Opening a CNC store can be a daunting task, but with the right equipment and expertise, it can be a very rewarding adventure. For those unfamiliar with the industry, CNC machining refers to the process of using computer-controlled machines to make precise parts and products. This technology revolutionizes manufacturing, enabling companies to produce high-quality components with increased speed and accuracy.

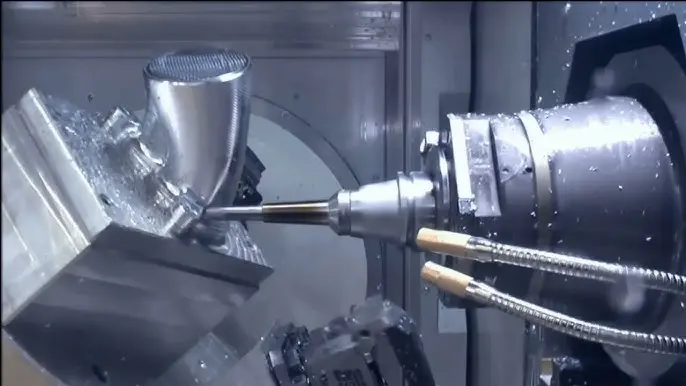

In order to build a successful CNC store, it is necessary to first determine the target market and the type of product to be produced. This will help you determine the specific equipment and software you need to invest in. For example, if you plan to specialize in producing complex metal parts, you may need advanced five-axis CNC machining equipment, such as those provided by Great Light, a leading manufacturer of five-axis CNC machining solutions.

Great Light’s advanced equipment and production technology enables enterprises to effectively solve complex metal parts manufacturing problems. Their one-stop post-processing and finishing services also ensure that products are delivered to customers in a timely and cost-effective manner. What’s more, excellent light can be used with a wide range of materials, allowing businesses to customize their products to meet specific requirements.

When building a CNC store, it is crucial to consider the workspace and infrastructure needed to support your operations. This includes ensuring you have the right facilities and with adequate power, ventilation and safety features. In addition, you need to invest in the necessary software and training to enable your employees to operate the CNC machine effectively.

When it comes to software, there are a wide variety of options, including computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. These tools enable designers and engineers to create and modify designs, simulate machining operations, and generate the necessary code to program CNC computers.

To ensure the success of your CNC store, it is also crucial to develop a comprehensive business plan that outlines your goals, target markets, marketing strategies and financial forecasts. This will help you get funding, attract customers and stay competitive in the market.

In short, opening a CNC store requires careful planning, investment in advanced equipment and software, and a deep understanding of the manufacturing process. By working with reputable suppliers such as Light Light and developing a solid business plan, you can build a thriving CNC store that provides high-quality products and excellent customer service.

FAQ:

Q: What is CNC machining and how does it work?

Answer: CNC machining refers to the process of using computer-controlled machines to manufacture precise parts and products. These machines are programmed using dedicated software, which allows them to perform complex operations with high accuracy and speed.

Q: What types of materials can be used in CNC processing?

A: CNC processing can be used with a variety of materials, including metals, plastics, wood and composites. The specific material used will depend on the product being manufactured and the desired characteristics of the final component.

Q: What is five-axis CNC machining and what are its benefits?

A: Five-axis CNC machining refers to the process of using a machine that can move on five different axes, allowing it to perform complex operations on complex parts. The benefits of five-axis CNC machining include increased speed, accuracy and flexibility, as well as the ability to manufacture complex geometric shapes and shapes.

Q: How to choose the right CNC machine for my business?

A: When choosing a CNC computer, consider the type of product you want to manufacture, the materials involved, and the level of complexity involved. Researching different vendors (such as highlights) and evaluating their devices, software and customer support are also essential.

Q: What kind of training and support are needed to operate a CNC machine?

A: To operate CNC machines effectively, you need to invest in comprehensive training and support. This may include software training, machine operation training, and ongoing technical support from suppliers. For example, excellent light provides expert training and support to ensure that its customers can optimize their equipment and achieve excellent results.