Beyond Price: Calculating the Long-Term Value of High-Accuracy CNC Auto Parts

In the automotive industry, where precision and reliability are non-negotiable, the choice of manufacturing technology can make or break a product’s success. CNC machining, particularly 5-axis CNC machining, has revolutionized how auto parts are produced, offering unparalleled accuracy and complexity. However, for engineers, purchasers, startup owners, and multinational company leaders, the decision to invest in high-accuracy CNC auto parts goes beyond the initial price tag—it’s about understanding the long-term value these parts bring to the table.

This blog post delves into the technical intricacies of CNC auto parts manufacturing, explores the long-term benefits of high-accuracy components, and provides a framework for calculating their total value over time. We’ll also highlight how Great Light, a leader in 5-axis CNC machining services, delivers precision and efficiency for automotive applications.

Introduction to CNC Machining and Its Role in Auto Parts Manufacturing

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-controlled tools remove material from a solid block to create precise parts. In the automotive industry, CNC machining is used to produce everything from engine components to suspension systems, offering advantages in precision, repeatability, and scalability.

The Power of 5-Axis CNC Machining

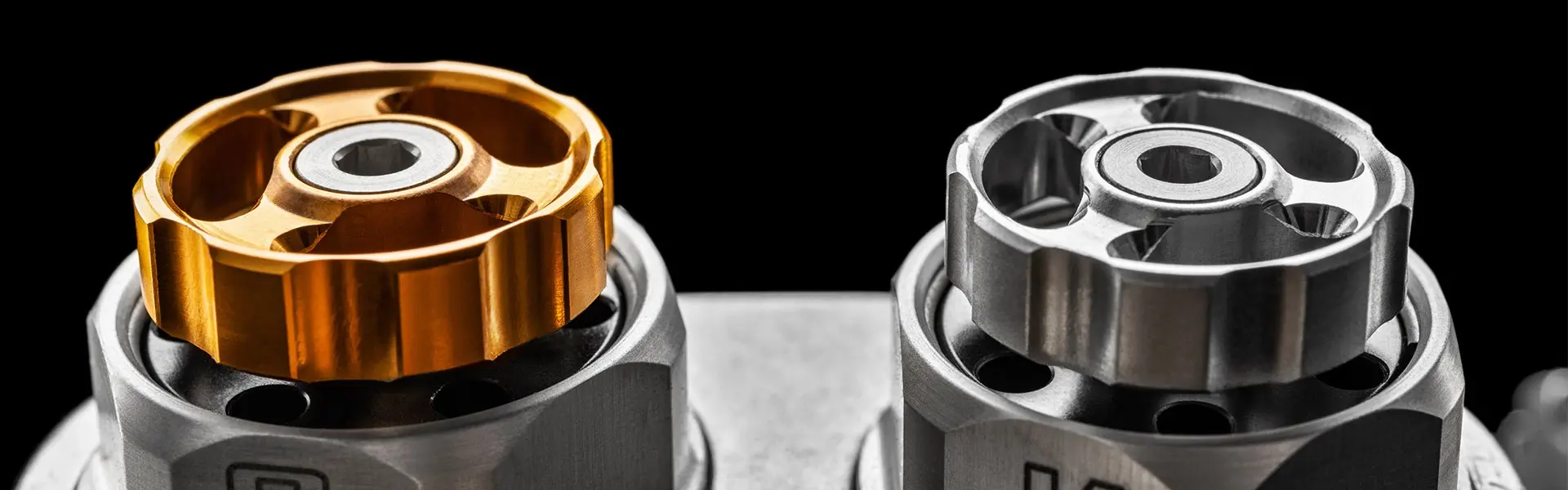

While traditional 3-axis CNC machines move along three linear axes (X, Y, Z), 5-axis CNC machining adds two rotational axes, allowing the cutting tool to approach the workpiece from virtually any angle. This capability is crucial for producing complex automotive parts with intricate geometries, such as:

- Turbocharger housings

- Transmission gears

- Engine blocks

- Suspension components

For high-accuracy applications, 5-axis CNC machining ensures tighter tolerances, fewer setups, and superior surface finishes—key factors that contribute to the long-term performance and reliability of auto parts.

Why Precision Matters in Automotive Parts

In automotive manufacturing, even the smallest deviation can lead to:

- Reduced performance

- Increased wear and tear

- Higher maintenance costs

- Safety risks

High-accuracy CNC auto parts mitigate these issues by ensuring that every component fits perfectly and functions as intended, ultimately extending the lifespan of the vehicle and reducing the total cost of ownership.

The Long-Term Value Proposition of High-Accuracy CNC Auto Parts

While high-accuracy CNC auto parts may come with a higher upfront cost, their long-term value far outweighs the initial investment. Here’s why:

1. Enhanced Performance and Efficiency

Precision-machined parts ensure optimal fit and function, leading to:

- Improved fuel efficiency: Tighter tolerances in engine components reduce friction and energy loss.

- Better power delivery: High-accuracy transmission parts ensure smoother gear shifts and less power wastage.

- Reduced emissions: Precision components help meet stringent environmental standards by optimizing combustion and reducing waste.

For electric vehicles (EVs), high-accuracy parts are even more critical, as they directly impact battery efficiency and range.

2. Increased Durability and Reduced Maintenance

High-accuracy parts are less prone to wear and tear, resulting in:

- Longer lifespan: Components like pistons, gears, and bearings last longer when machined to exact specifications.

- Fewer breakdowns: Precision parts reduce the likelihood of mechanical failures, minimizing downtime and repair costs.

- Lower maintenance frequency: With less wear, vehicles require fewer tune-ups and part replacements.

3. Cost Savings Over Time

While the initial cost of high-accuracy CNC parts may be higher, the savings accumulate over the vehicle’s lifecycle:

- Reduced replacement frequency: Durable parts mean fewer replacements, lowering long-term material costs.

- Minimized labor costs: Less frequent maintenance and repairs reduce labor expenses.

- Energy savings: Improved efficiency translates to lower fuel or energy consumption, a significant factor for fleet operators and environmentally conscious consumers.

Calculating the Total Cost of Ownership (TCO) for CNC Auto Parts

To truly understand the value of high-accuracy CNC auto parts, it’s essential to calculate their Total Cost of Ownership (TCO). TCO goes beyond the purchase price, factoring in all costs associated with owning and operating the part over its lifespan.

Key Factors in TCO Calculation

- Initial Cost: The upfront price of the part.

- Maintenance Costs: Expenses for routine upkeep and repairs.

- Replacement Frequency: How often the part needs to be replaced.

- Downtime Costs: Lost productivity or revenue due to part failure.

- Performance Gains: Efficiency improvements that reduce operational costs (e.g., fuel savings).

A Simple TCO Formula

[ \text{TCO} = \text{Initial Cost} + \left( \text{Maintenance Cost per Year} \times \text{Expected Lifespan} \right) + \left( \text{Replacement Cost} \times \text{Number of Replacements} \right) – \left( \text{Performance Gains} \times \text{Value per Unit} \right) ]

Example Calculation: Standard vs. High-Accuracy CNC Part

Consider a hypothetical scenario comparing a standard-accuracy transmission gear to a high-accuracy CNC-machined gear over a 10-year period:

- Standard Gear:

- Initial Cost: $500

- Maintenance Cost per Year: $100

- Expected Lifespan: 5 years (requires replacement every 5 years)

- Performance Gains: None

- High-Accuracy CNC Gear:

- Initial Cost: $800

- Maintenance Cost per Year: $50

- Expected Lifespan: 10 years (no replacement needed)

- Performance Gains: 5% fuel efficiency improvement, saving $200 per year

TCO for Standard Gear: [ \text{TCO} = 500 + (100 \times 10) + (500 \times 1) – 0 = 500 + 1000 + 500 = $2000 ]

TCO for High-Accuracy CNC Gear: [ \text{TCO} = 800 + (50 \times 10) + 0 – (200 \times 10) = 800 + 500 – 2000 = -$700 ]

In this example, the high-accuracy CNC gear not only saves money but effectively pays for itself through reduced maintenance, no replacements, and significant performance gains.

Real-World Applications and Case Studies

High-accuracy CNC auto parts deliver measurable benefits across various automotive applications:

Engine Components

- Pistons and Cylinder Heads: Precision machining ensures optimal compression and combustion, improving power output and fuel efficiency.

- Turbocharger Housings: Complex geometries machined with 5-axis CNC technology enhance airflow and boost performance.

Transmission Systems

- Gears and Shafts: High-accuracy parts reduce friction and wear, extending the life of the transmission and improving shift quality.

Suspension and Steering

- Control Arms and Steering Knuckles: Precision components ensure accurate alignment and handling, enhancing safety and ride comfort.

Electric Vehicle (EV) Components

- Battery Housings and Cooling Systems: High-accuracy machining ensures efficient thermal management, extending battery life and range.

For startups innovating in the EV space, precision parts are critical for meeting performance targets and regulatory standards.

Why Choose Great Light for Your CNC Auto Parts Needs

When it comes to manufacturing high-accuracy CNC auto parts, Great Light stands out as a leader in 5-axis CNC machining services. Here’s why:

Advanced 5-Axis CNC Machining Capabilities

- Complex Geometries: Our machines handle intricate designs with ease, ensuring precision for even the most challenging parts.

- Tight Tolerances: We achieve tolerances as tight as ±0.001 inches, meeting the strictest automotive standards.

- Scalability: From prototypes to high-volume production, we adapt to your needs without compromising quality.

One-Stop Solution for Post-Processing and Finishing

- Heat Treatment: Enhance strength and durability.

- Surface Finishing: Polishing, anodizing, or coating for improved aesthetics and performance.

- Quality Control: Rigorous inspections ensure every part meets your specifications.

Online Customization and Rapid Prototyping

- Instant Quotes: Upload your design and get pricing in minutes.

- Fast Turnaround: Accelerate your prototype to production timeline with our efficient processes.

For multinational companies, our scalable solutions ensure consistent quality across large orders. For startups, our rapid prototyping capabilities help you iterate quickly and bring innovations to market faster.

The Environmental Impact: Precision Meets Sustainability

High-accuracy CNC auto parts don’t just benefit your bottom line—they also contribute to a greener future:

- Improved Fuel Efficiency: Precision parts reduce energy waste, lowering emissions.

- Longer Part Lifespan: Fewer replacements mean less material waste and reduced environmental footprint.

- Optimized EV Performance: Precision components enhance battery efficiency, supporting the shift to sustainable transportation.

For businesses committed to sustainability, investing in high-accuracy parts is a step toward meeting environmental goals.

Conclusion: Precision Pays Off

In the automotive industry, the true value of a part isn’t measured by its price tag alone—it’s about the long-term performance, durability, and efficiency it delivers. High-accuracy CNC auto parts, manufactured with advanced 5-axis CNC machining, offer a compelling return on investment by reducing maintenance, extending lifespan, and enhancing vehicle performance.

At Great Light, we’re committed to helping you unlock this value. Whether you’re an engineer designing the next breakthrough component or a purchaser ensuring your supply chain is optimized, our precision machining services are tailored to your needs.

Ready to calculate the long-term value for your project? Customize your 5-axis CNC machining project with Great Light today and experience the difference precision makes.