The inner ear, particularly the cochlea, remains a largely unexplored area in medicine due to its complex and inaccessible anatomy. This poses a real barrier to treating hearing loss and other inner ear diseases. For more than a decade, a team of doctors and engineers at Columbia University has been working to develop a microneedle designed to improve medical outcomes in hearing loss. Additive manufacturing played a key role in the production of this device.

With the help ofIn 3D printing, otolaryngologist Anil Lalwani and mechanical engineer Jeffrey Kysar have successfully designed and produced an ultra-thin device: 3D printed microneedles for precision medicine in the inner ear . Both men believe the invention will represent a major advance in current treatments, particularly for previously inaccessible areas of the cochlea. To create these fine microneedles, they used two-photon lithography, a 3D printing technology used to create high-resolution structures. This makes the needle more precise than existing devices while still being strong enough for practical use.

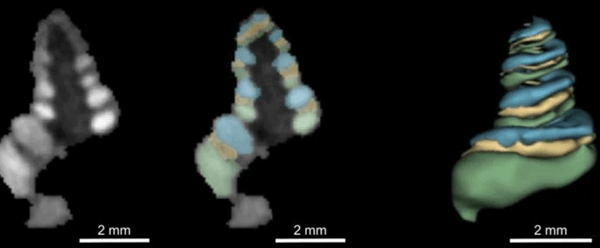

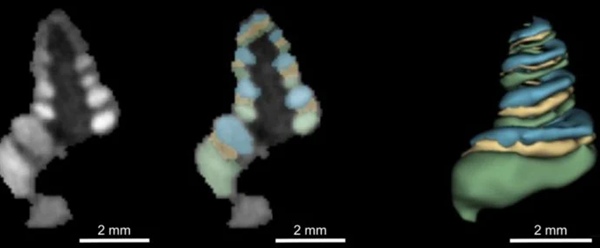

Microneedles inject contrast media into the inner ear to detect changes in the cochlea, which can help diagnose conditions such as Ménière’s disease. guinea pig cochleaMRI images show the different compartments of the cochlea. (Photo credit: Anil Lalwani/Columbia University Vagelos College of Physicians and Surgeons)

One of the main difficulties lies in the complex anatomy of the cochlea, which makes the implementation of the treatment particularly difficult. Indeed, to reach the damaged cells, you have to go throughThe 2 mm wide and very fragile membrane often tears when using conventional instruments, which can lead to hearing loss and even balance disorders. This allows researchers to better understand the factors behind this break. The team then conceptualized the membrane as a stretched canvas: if the inserted instrument is too large, it can cause a tear. 3D printed microneedles are therefore designed to be the same width as a human hair. The main goal is to treat the cochlea without damaging the membrane. Additionally, microneedles can extract fluid from the cochlea, making it easier to diagnose inner ear diseases such as Ménière’s disease, a condition that causes dizziness, nausea and hearing loss.

Many surgeries have been performed on animals without negative effects or hearing loss, and the membranes recovered within two days of each surgery. Currently, people believe3D printed microneedles could transform inner ear treatment through more precise intervention. Dr. Anil Lalwani emphasized: “It is no exaggeration to say that our microneedles could be the key to precision medicine in the inner ear. »

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.