Introduction to Metal Injection Molding

Metal Injection Molding (MIM) is an advanced manufacturing process that merges the design flexibility of plastic injection molding with the strength and material options of powdered metallurgy. By blending fine metal powders with a thermoplastic binder to form a feedstock “green part,” MIM enables the mass production of complex, high-precision metal components with tight tolerances and excellent surface finishes. From medical implants to automotive fuel injectors, Metal Injection Molding unlocks new possibilities in part geometry, material performance, and cost efficiency.

What Is Metal Injection Molding?

The Core Steps

- Mixing & Pelletizing

- Metal powder (e.g., stainless steel, titanium, Inconel) is combined with a binder system.

- The blend is extruded into uniform pellets for consistent feed into injection machines.

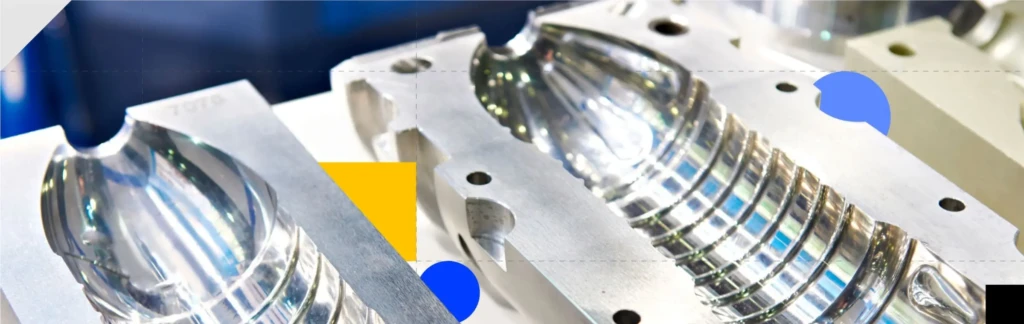

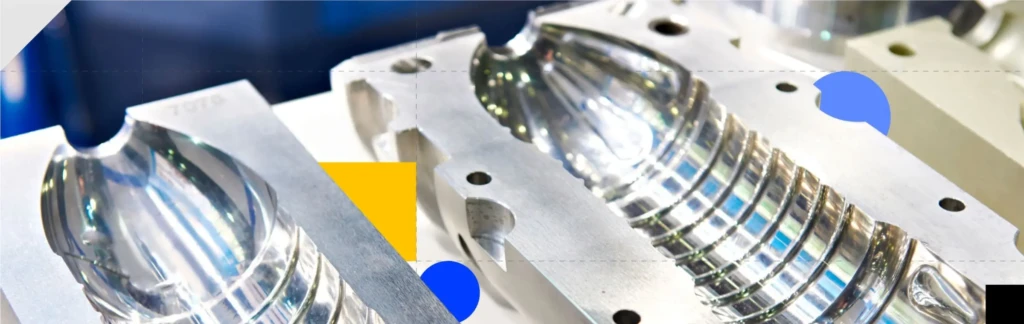

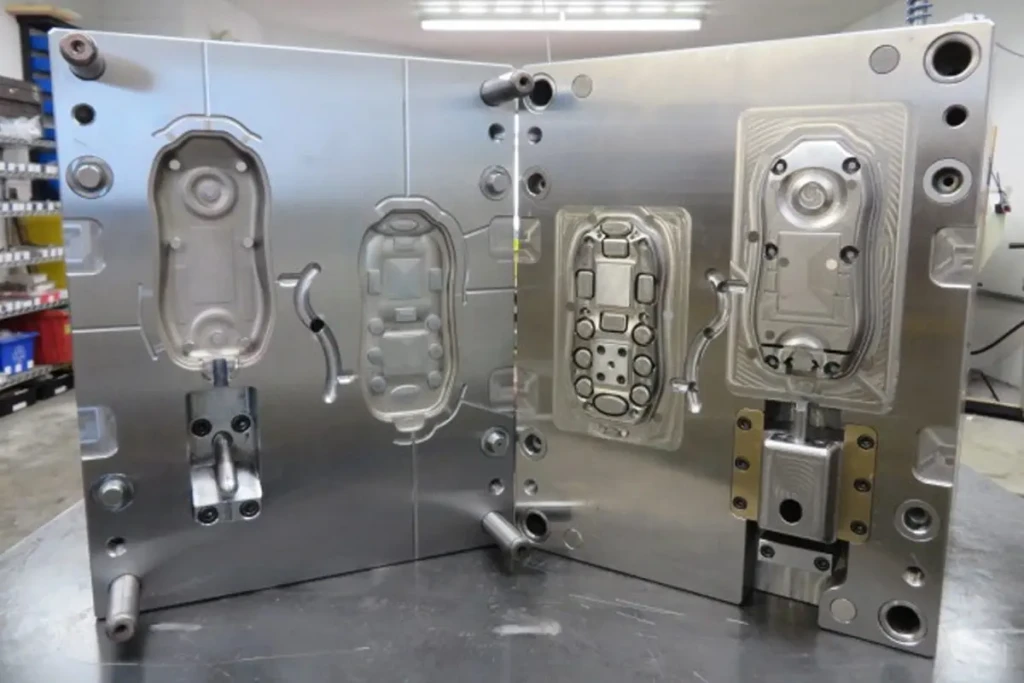

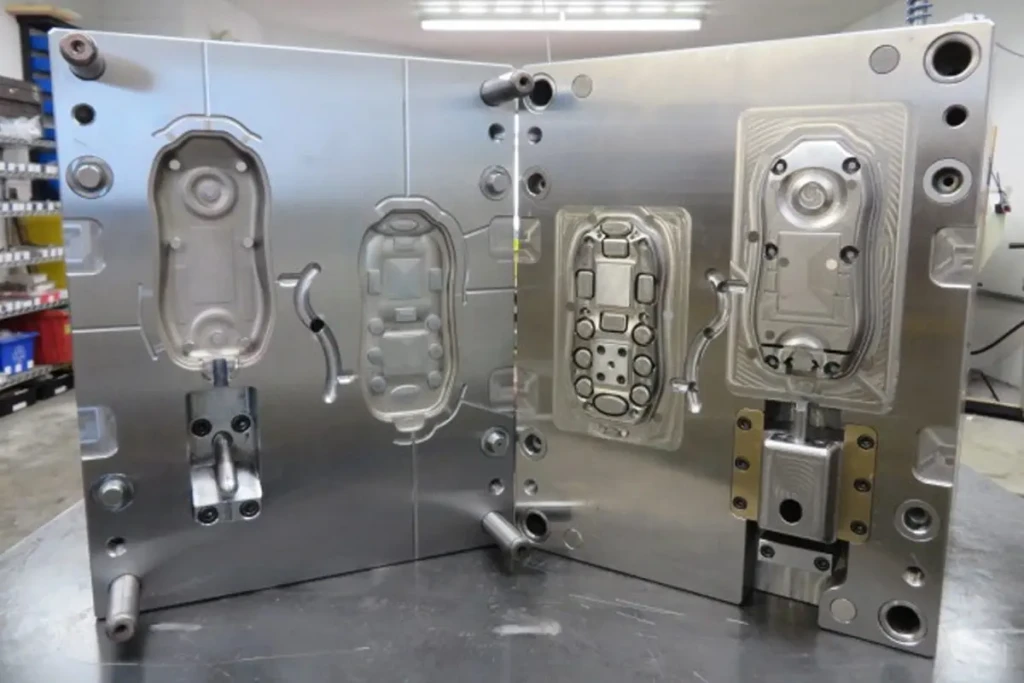

- Injection Molding

- Pellets are heated and injected into precision steel molds under high pressure.

- Green parts solidify in the mold, capturing intricate features, thin walls, and undercuts.

- Debinding

- Solvent or thermal methods remove the binder, creating a porous “brown part.”

- Sintering

- Brown parts are heated near the melting point of the metal, fusing powder particles and achieving > 95% theoretical density.

Materials & Capabilities

- Common Alloys: 316L stainless steel, 17-4 PH, 304L, titanium, nickel alloys

- Tolerances: ± 0.1 mm for most geometries; ± 0.05 mm achievable on critical features

- Surface Finish: Ra 0.4–1.6 µm post-sintering; further polishing or coatings optional

Metal Injection Molding vs. Die Casting

| Aspect | MIM Metal Injection Molding | Die Casting |

|---|---|---|

| Material Variety | Wide range of stainless, tool, superalloys | Primarily aluminum, zinc, magnesium alloys |

| Complexity | Highly intricate features, fine structures | Moderate; limited by draft angles |

| Tolerance | Tight: down to ± 0.05 mm | ± 0.1–0.25 mm |

| Production Volume | Medium to high | Very high |

| Tooling Cost | Moderate (steeper sintering fixtures) | High (expensive die creation) |

For parts requiring exotic alloys, internal channels, or micro-scale detail, Metal Injection Molding vs. die casting clearly favors MIM despite slightly higher per-part cost at large volumes.

Key Advantages of Metal Injection Molding

Design Freedom

- Undercuts & Thin Walls: Walls as thin as 0.3 mm and internal geometries impossible by machining or casting.

- Part Consolidation: Multiple subcomponents can be molded as a single piece, reducing assembly costs.

High Throughput & Low Unit Cost

- After initial tooling, cycle times range from 15–60 seconds per shot.

- Economies of scale drive down per-part cost for batches from thousands to millions.

Superior Material Properties

- Sintered density exceeds 96–98% of wrought material.

- Mechanical performance on par with wrought or machined parts, including high fatigue strength and corrosion resistance.

Typical Applications for MIM Metal Injection Molding

- Medical & Dental Devices: Surgical instruments, implants, orthodontic components

- Automotive: Precision fuel injectors, valve guides, turbocharger vanes

- Consumer Electronics: Micro Gears, connectors, heat sinks

- Firearms & Defense: Locking blocks, firing pins, sight components

- Industrial: Nozzles, micro-pumps, sensors

Selecting a Metal Injection Molding Supplier

When evaluating Metal Injection Molding services or Metal Injection Molding companies, consider:

- Material Expertise

- Does the supplier offer a broad alloy portfolio (e.g., stainless, tool steels, superalloys)?

- Quality Systems

- Are they certified to IATF 16949 (automotive) or ISO 13485 (medical)?

- Tooling & Design Support

- In-house mold flow analysis, design for manufacturability (DFM) reviews, and mold maintenance.

- Post-Processing Capabilities

- Heat treatment, finish machining, coating, and assembly services.

Innovations & Emerging Trends in Metal Injection Molding

3D Printed Metal Injection Molds

Hybrid workflows now leverage additive manufacturing to produce molds with conformal cooling channels, reducing cycle time and improving dimensional stability.

Liquid Metal Injection Molding

New binder systems allow low-pressure molding of liquid metals, enhancing feedstock flow and enabling even finer feature resolution.

Alternative to Metal Injection Molding

Processes like micro powder injection molding (µPIM) and metal binder jetting are gaining traction for ultra-small, highly complex parts.

Conclusion

Metal Injection Molding stands at the intersection of precision, versatility, and scalability. Whether you require high-volume stainless steel components for automotive applications or intricate titanium implants for medical devices, MIM delivers unmatched detail, performance, and cost-effectiveness. Partnering with a seasoned Metal Injection Molding manufacturer—especially one offering turnkey design, prototyping, and post-processing—ensures your project benefits from the full spectrum of MIM’s capabilities. For the best in online customization of metal parts, explore Great Light’s comprehensive MIM and 5 Axis CNC machining services today.