imagine3D printed materials can detect problems before they become serious. Engineers at the University of Glasgow are working to achieve this with a system that can simulate the physical properties of self-sensing composite materials. These materials can measure voltage, charge or damage simply by analyzing electrical current, allowing their condition to be monitored in real time. This opens up new perspectives in safety and quality assurance in many sectors.

How do these self-sensing materials work? The integration of carbon nanotubes into these materials allows them to conduct electric current, according to a press release from the University of Glasgow. This phenomenon, called piezoresistiveness, allows the material to control the integrity of its own structure. If the current changes, it can indicate deformation, such as compression or tension, allowing faults to be identified and corrected before they become worse.

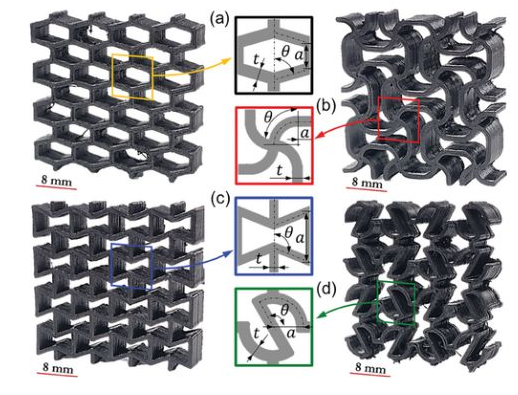

Four different networks created by engineers at the University of Glasgow (Photo credit: University of Glasgow)

Development and testing of self-determined materials

James, University of GlasgowProfessor Shanmugam Kumar from the Watt School of Engineering led the research. He explains: “Giving piezoresistive behavior to 3D printed honeycomb materials allows their performance to be monitored without adding additional hardware.

By adding polyetherimide(PEI) and carbon nanotubes, researchers developed four lightweight network structures produced by fused filament fabrication (FFF). These “self-sensing building materials” are then tested to assess their rigidity, strength, energy absorption and, most importantly, their ability to self-monitor.

Engineers have developed computer models that predict how these materials will respond to different mechanical stresses. These predictions were verified in real-world testing, where infrared thermal analysis visualized the flow of electrical current through the material. This confirms the accuracy of the model and the ability of the material to detect deformations due to changes in electrical resistance.

Crystal lattices and their thermal imaging (Photo credit: University of Glasgow)

Professor Kumar explains how the model they developed will help optimize the design of self-sensing materials:“Although researchers have known about these properties for some time, what we have not been able to do is provide a way to know in advance how effective new attempts at creating innovative sensor-sensing materials will be. “We often have to rely on them.”

What are the possible applications of 3D printed self-detecting materials?

The possibilities offered by these materials are vast. In the aerospace and automotive industries, they can improve safety and maintenance by monitoring the integrity of critical components in real time. For infrastructure such as bridges or tunnels, these materials can detect structural problems before they develop into major failures. Engineers believe these findings could also have applications in areas such as smart orthopedics, structural monitoring, sensors and even batteries.

Professor Kumar also spoke about the future prospects:

“While we focus in this paper on PEI materials embedded with carbon nanotubes, the multi-scale finite element modeling on which our results are based can be applied to other materials created by additive manufacturing. »

“We hope this approach will encourage other researchers to develop new building materials with autonomous sensing capabilities, unlocking the full potential of this approach in materials design and development across all industries.”

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.