Copper CNC machining: an accurate process

Copper is a versatile and valuable metal used in a wide range of industries from electronics to construction. When it comes to making copper parts, CNC machining is a popular choice because of its accuracy, accuracy and speed. In this article, we will explore the process of copper CNC machining, its benefits, and why it is the preferred method for producing high-quality copper parts.

Copper CNC processing process

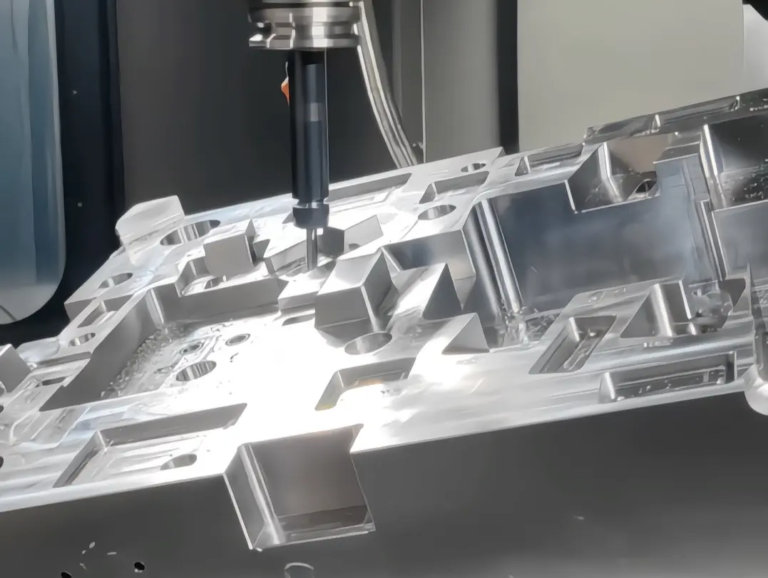

CNC machining is a subtraction manufacturing process that uses a computer-controlled machine to remove materials from workpieces. In the case of copper CNC processing, the process begins with a piece of copper soup and is then fed to a CNC milling machine. Program the machine to remove a small amount of copper with a milling cutter or drill bit at a time to create the desired shape and size.

CNC milling machines use a combination of computer-aided design (CAD) software and artificial intelligence to control cutting tools to ensure accurate and accurate cutting. The process is highly repetitive and can produce the same parts with precise tolerances.

Benefits of Copper CNC Processing

Copper CNC machining provides a variety of benefits to other manufacturing methods, including:

1. Accuracy: CNC machining enables the production of parts with accuracy tolerances, making them ideal for applications requiring high precision.

2. Speed: Copper CNC machining is a fast process that can produce parts quickly and efficiently.

3. Cost-effectiveness: While the initial investment in CNC machinery may be higher, production costs are lower in the long run due to improved accuracy and efficiency.

4. Flexibility: Copper CNC machining can be used to produce a wide range of parts, from small electronic components to large building materials.

Application of copper CNC processing

Copper CNC processing is used in a variety of industries, including:

1. Electronics: Copper is widely used in the electronics industry, especially in the production of computer components, wiring and circuits.

2. Construction: Copper is used in construction for pipelines, piping and other building applications.

3. Automotive: Copper is used in wiring, brake pads and other components in the automotive industry.

in conclusion

In short, copper CNC machining is an accurate and effective manufacturing process that provides a range of benefits over other methods. Its accuracy, speed, cost efficiency and flexibility make it the preferred method of producing high-quality copper parts. Whether you want to produce small electronics or large building materials, CNC machining is the ideal solution.

FAQ

Q: What is copper CNC processing?

A: Copper CNC machining is a subtraction manufacturing process that uses a computer-controlled machine to remove material from copper workpieces.

Q: What are the benefits of copper CNC processing?

A: The benefits of CNC machining include accuracy, speed, cost-effectiveness, and flexibility.

Q: Which industries use copper CNC processing?

A: Copper CNC processing is used in the electronics, construction and automotive industries.

Q: What is the accuracy tolerance for copper CNC machining?

A: The accuracy tolerance of copper CNC machining depends on the machine and specific application, but is usually within ±0.01mm.

Q: How long does the copper CNC processing process take?

A: The copper CNC machining process usually takes several hours to several days, depending on the complexity of the part and the size of the batch processing.