Professional CNC machining services in San Diego

In the heart of San Diego, a city known for its vibrant economy and rich industrial landscape, is a niche for precise processing services that meet the strictest standards of quality and precision standards. Among the providers of such services, Excellent Lighting is an excellent beacon, offering advanced five-axis CNC machining capabilities that meet the needs of a wide range of industries from aerospace to automotive, from medical to consumer electronics. This blog post delves into the CNC machining field in San Diego, highlighting the benefits of choosing professional services like quality lighting for all your precise machining needs.

The importance of precision in CNC machining

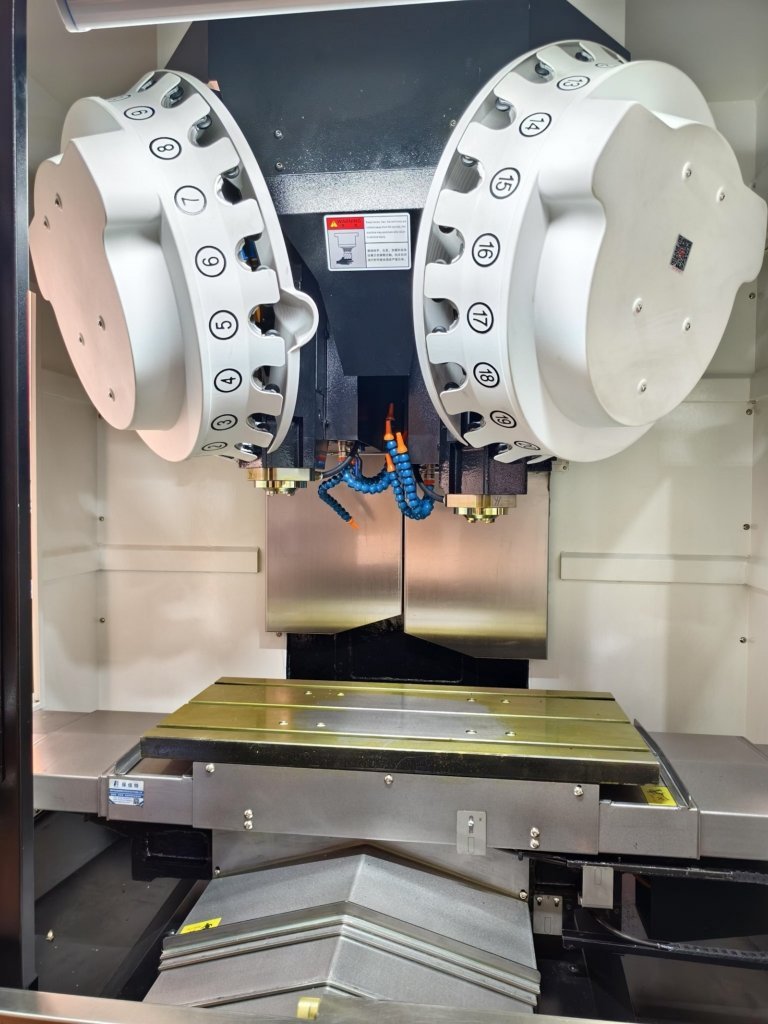

Accuracy is the cornerstone of CNC machining. The ability to shear, drill and form materials with micron-scale precision makes CNC machining different from traditional machining methods. In industries where safety, performance and reliability are critical, the accuracy provided by CNC machining is essential. The light with its state-of-the-art five-axis CNC machining equipment is excellent and is at the forefront of delivering precise parts that meet and exceed these expectations.

Advantages of choosing headlights for CNC machining in San Diego

Advanced technology: Great Light has cutting-edge five-axis CNC machining equipment that can easily and accurately process complex geometric shapes and shapes. This technology makes it difficult or impossible to produce parts using conventional machining techniques.

Customization and rapid prototyping: Understand that each customer has unique needs, Great Light offers custom choices for a wide range of materials including metals, plastics and composites. Coupled with the fast prototyping function, it means that customers can quickly go from design to production, greatly reducing development time and cost.

One-stop post-processing and completion service: What makes the lighting stand out is that it not only provides processing services, but also provides comprehensive post-processing and finishing services. This includes treatments such as anodization, plating and painting to ensure that the parts are not only manufactured accurately, but also the exact specifications required by the customer.

- Expertise and support: The great team includes experienced engineers and technicians who are committed to ensuring that each project is handled with maximum care and professionalism. From initial design consultation to final inspection and shipping, customers receive unparalleled support and expertise.

Application of CNC machining in San Diego

The applications of CNC machining in San Diego are huge and varied. For the aerospace industry, precise parts are crucial to the production of aircraft and spacecraft components. In the medical field, CNC machining is used to produce complex parts for medical devices and implants. The automotive industry also benefits from CNC machining, whose parts such as engine components and dashboard trim are manufactured at precision and speed.

in conclusion

In short, for San Diego businesses and individuals, finding reliable partners for CNC machining needs, Great Light provides a comprehensive solution. With its advanced five-axis CNC machining capabilities, commitment to accuracy, and one-stop service for post-processing and finishing, the great lighting stance proves innovation and customer satisfaction. Whether you are in the initial stages of product development or want to optimize the manufacturing process, Great Light’s professional CNC machining services are tailored to meet your unique requirements to ensure that your parts are not only in specifications, but also delivered on time and within budget.

FAQ

What materials can be processed with CNC machining?

- It can handle a variety of materials including metals (aluminum, stainless steel, titanium), plastics and composites.

What is the typical lead time for a CNC machining project?

- Delivery times vary by project complexity and material availability. Quick prototyping services are available for emergency projects.

Is the excellent lightweight handle complex geometry and custom design OK?

- Yes, Great Light’s five-axis CNC machining equipment is able to handle complex geometry and custom designs in an accurate and accurate manner.

Post-processing and service completion?

- Yes, Great Light offers a comprehensive post-processing and completion service including anodization, electroplating, painting and more.

- How does highlight ensure the quality of its CNC machining parts?

- Great Light adopts strict quality control measures, including preliminary inspections, in-process inspections and final inspections, and then ships the parts to the customer.