As a professional five-axis CNC machining manufacturer, Great Light has become a trusted partner for businesses and individuals seeking high-quality metal parts manufacturing solutions. With advanced five-axis CNC machining equipment and production technology, Great Light can solve complex metal parts manufacturing problems while providing one-stop post-processing and finishing services. This article will dig into the world of CNC machining, exploring the importance of its applications, benefits and choosing the right manufacturing partner.

CNC machining is a subtraction manufacturing process that involves using a computer-controlled machine to remove material from workpieces, thereby creating custom designed parts or products. This process offers many benefits, including high accuracy, accuracy and speed. CNC machining is widely used in a variety of industries such as aerospace, automotive, medical and consumer products to produce complex parts and components.

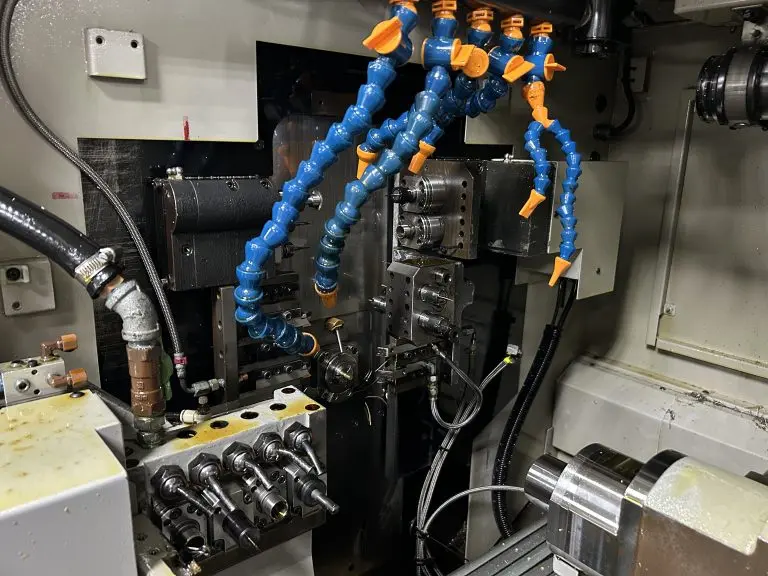

Great Light’s five-axis CNC machining service provides unparalleled flexibility and versatility, allowing for the production of complex parts with complex geometries. The company’s advanced equipment and production technology ensures that all parts meet the highest quality standards and meet the strictest specifications and tolerances.

One of the key advantages of CNC machining is its ability to handle a wide range of materials, including metals, plastics and composites. Great Light’s expertise in custom precision machining allows companies to work with a wide range of materials to provide customers with one-stop solutions that meet all their manufacturing needs.

In addition to its technical features, Great Light is committed to providing excellent customer service to ensure that all projects are completed and delivered on time with the highest quality standards. The company’s experienced team of professionals works closely with clients to understand their specific requirements and provide tailored solutions that meet their unique needs.

When choosing a CNC machining partner, several factors must be considered, including the company’s expertise, equipment and production capacity. Great Light’s commitment to quality, innovation and customer satisfaction makes it an ideal partner for businesses and individuals seeking high-quality metal parts manufacturing solutions.

In short, Great Light’s CNC machining services provide comprehensive solutions for businesses and individuals seeking high-quality metal parts manufacturing solutions. With its advanced equipment, production technology and commitment to customer satisfaction, Great Light is the ideal partner for companies looking to produce complex parts and components with high precision and accuracy.

FAQ:

Q: What is CNC processing?

A: CNC machining is a subtraction manufacturing process that involves using a computer-controlled machine to remove material from workpieces, thereby creating custom designed parts or products.

Q: What are the benefits of CNC processing?

A: CNC machining provides many benefits, including high precision, accuracy and speed, making it an ideal process for producing complex parts and components.

Q: What materials can be used in CNC processing?

A: CNC processing can handle a variety of materials, including metals, plastics and composites.

Q: What is five-axis CNC machining?

A: Five-axis CNC machining is a CNC machining that involves the use of a machine with five axes of motion, so that complex parts with complex geometries can be produced.

Q: How to choose the right CNC processing partner?

A: When choosing a CNC processing partner, please consider factors such as company expertise, equipment and production capacity, as well as its commitment to quality, innovation and customer satisfaction.

Q: What kind of services are provided and what kind of services are provided?

A: Great Light provides a range of services including custom precision machining, one-stop post-processing and completion services, as well as expert consultation and support.

Q: Can you use a beautiful work with custom design?

A: Yes, excellent light can be used with custom designs, providing tailored solutions to meet the unique needs of each customer.