The history of computer numerical control (CNC) processing can be traced back to the early 20th century, when the first numerical control (NC) machine was developed. These early machines used punch cards or magnetic tape to control the movement of the machine tool, thus making it more precise and efficient. Over the years, CNC technology has developed significantly with the introduction of computer controls, advanced software and precision machinery.

In the 1940s and 1950s, the first NC machine was developed to control the motion of the machine using punch cards or magnetic tapes. These early machines are mainly used to process complex shapes and curves, and are often used in the aerospace and defense industries. The first CNC machine was developed in the 1960s and used computers to control the motion of the machine tool. This marks a significant improvement in accuracy and efficiency and paves the way for widespread adoption of CNC technology.

Microprocessor and computer-aided design (CAD) software were seen in the 1970s and 1980s, further improving the accuracy and efficiency of CNC machining. During this period, the development of CNC machining centers has also become more common for integrating multiple machine tools into one unit. These machining centers allow the production of complex parts and components with high precision and speed.

In the 1990s and 2000s, the development of advanced CNC software and hardware continued to improve the accuracy and efficiency of CNC machining. During this period, the introduction of high-speed machining can increase processing speed and improve surface finishes, which also become more common during this period. Today, CNC machining has become a key component of modern manufacturing, used in a wide range of industries including aerospace, automotive, medical and consumer products.

Compared with traditional processing methods, CNC machining has many advantages, including improved accuracy, increased efficiency and reduced labor costs. Human intervention in CNC machines can run at least 24/7 and can produce complex parts and components with high accuracy and accuracy. Additionally, CNC machining allows the production of small batches or disposable parts, making it an ideal solution for prototyping and low volume production.

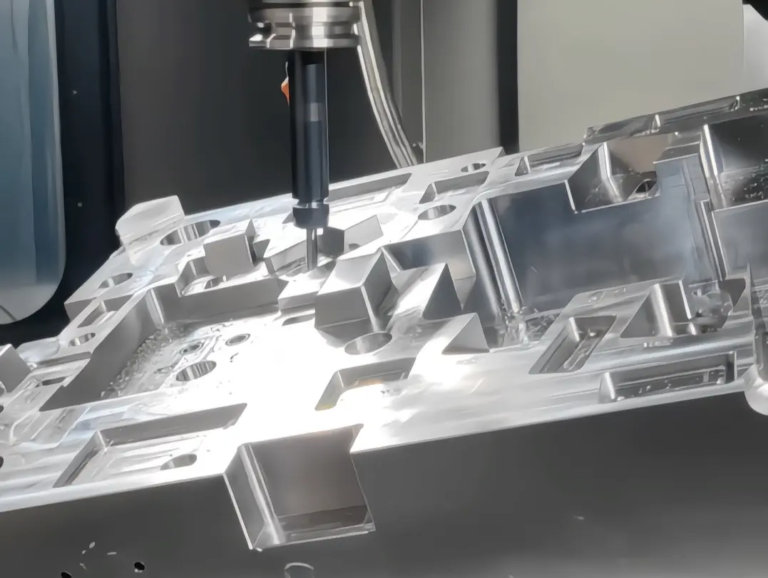

From an excellent perspective, we focus on five-axis CNC machining, which allows the production of complex parts and components with high accuracy and accuracy. Our advanced CNC equipment and production technology enables us to solve metal parts manufacturing problems and provide one-stop post-processing and finishing services. We can quickly customize and process most materials, making us the first choice for custom precision machining.

In short, with the development of numerical control machines and the introduction of computer control, the origin of CNC processing can be traced back to the early 20th century. Over the years, CNC technology has developed significantly with advances in software, hardware and precision machinery. Today, CNC machining has become a key component of modern manufacturing, providing improved accuracy, increased efficiency and reduced labor costs. Whether you need customized precision machining or small batch production, the advantages of meeting all CNC machining needs.

FAQ:

Q: What is CNC processing?

A: CNC machining is a manufacturing process that uses computer numerical control to control the machine tools and produce complex parts and components with high accuracy and accuracy.

Q: What are the advantages of CNC processing?

A: CNC machining provides many advantages, including improved accuracy, increased efficiency and reduced labor costs. It also allows small batches or disposable parts to be produced, making it an ideal solution for prototyping and low-volume production.

Q: What is five-axis CNC machining?

A: Five-axis CNC machining is a CNC machining that allows the production of complex parts and components with high accuracy and accuracy. It uses five axes of motion to combine shapes and curves.

Q: What materials can be used in CNC processing?

A: Most materials can be used in CNC processing, including metals, plastics and composites. It is very obvious that we can quickly customize and process most materials.

Q: What is the difference between CNC processing and traditional processing?

Answer: Compared with traditional processing methods, CNC processing provides improved accuracy, improved efficiency and reduced labor costs. It also allows for the production of complex parts and components with high precision and accuracy.