As professionals in the CNC machining field, it is necessary to understand the latest technologies and innovations to improve the efficiency and accuracy of the machining process. Such a technique is a CNC milling simulator, a software tool designed to simulate the machining process, allowing manufacturers to test and optimize their CNC programs before running the actual machine.

The CNC milling simulator is a virtual environment that takes into account the kinematics, dynamics and other factors that affect the machining process, repeating the behavior of a real CNC milling machine. This allows manufacturers to test their CNC procedures, identify potential errors or collisions, and optimize the machining process to achieve the desired results.

One of the main benefits of using a CNC milling simulator is the ability to reduce the risk of errors and collisions during machining. By simulating the machining process, manufacturers can identify potential problems and make necessary adjustments before running the program on the actual machine. This not only saves time and money, but also reduces the risk of damaging the machine or workpiece.

Another important advantage of CNC milling simulator is its ability to optimize the machining process. By analyzing the simulation results, manufacturers can identify areas of improvement, such as reducing machining time, improving surface finishes, or extending tool life. This allows manufacturers to refine their CNC plans and achieve the desired results more effectively.

In addition to its technical interests, the CNC milling simulator offers a range of economic benefits. By reducing the risk of errors and collisions, manufacturers can save on repair costs, reduce downtime and increase productivity. Additionally, the simulator allows manufacturers to run CNC programs on real machines to test and optimize their CNC programs, reducing the need for expensive trials and errors.

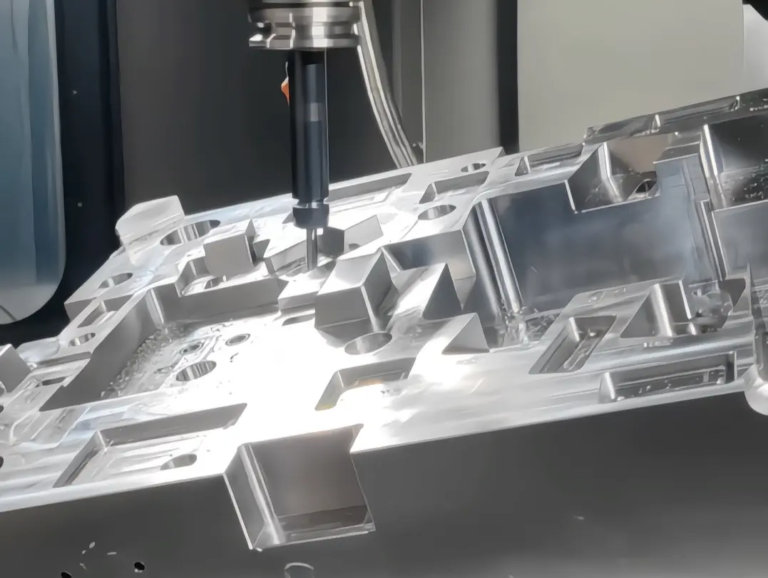

A professional five-axis CNC machining manufacturer, we understand the importance of leveraging innovative technologies such as CNC milling simulators to improve our machining services. Our advanced five-axis CNC machining equipment and production technology enables us to professionally solve metal parts manufacturing problems, and we also provide one-stop post-processing and finishing services. Most materials can be quickly customized and processed, making us the first choice for customized precision machining.

In short, the CNC milling simulator is a powerful tool that helps manufacturers improve the efficiency and accuracy of the machining process. By simulating the machining process, manufacturers can test and optimize their CNC procedures, reduce the risk of errors and collisions, and achieve the expected results more effectively. As a professional five-axis CNC machining manufacturer, Great Light is committed to providing customers with high-quality machining services using innovative technologies such as CNC milling simulators.

FAQ:

Q: What is a CNC milling simulator?

A: The CNC milling simulator is a software tool designed to simulate machining processes, allowing manufacturers to test and optimize their CNC programs before running them on a real machine.

Q: What are the benefits of using CNC milling simulator?

A: The benefits of using CNC milling simulators include reducing the risk of errors and collisions, optimizing the machining process, and saving time and money.

Q: Can CNC milling simulator be used for five-axis CNC machining?

A: Yes, CNC milling simulators can be used for five-axis CNC machining, allowing manufacturers to test and optimize their CNC procedures for complex machining operations.

Q: How to get started with CNC milling simulator?

A: First, you can contact professional five-axis CNC machining manufacturers like great light, who can give you more information on how to use the simulator and improve machining services.

Q: What materials can be customized and processed using CNC milling simulator?

A: Most materials can be quickly customized and processed using CNC milling simulators, including metals, plastics and other materials.