Introduction to CNC machining work

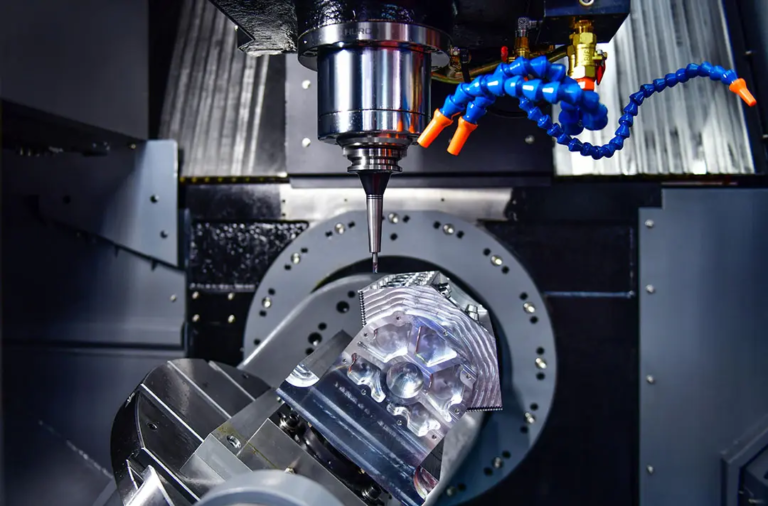

In the manufacturing world, computer numerical control (CNC) processing plays a crucial role in the production of high-precision parts and products. CNC machining involves the use of computer-controlled machines to cut, drill and shape materials such as metal, plastic and wood. With the growing demand for customized and complex products, CNC machining has become a key aspect of various industries, including aerospace, automotive, medical and consumer products. In this article, we will dig into the world of CNC machining work and explore the services, benefits and FAQs offered.

What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to produce high-precision parts and products. These machines can perform various operations such as milling, turning, drilling and grinding to create complex shapes and designs. The use of CNC machining enables manufacturers to produce parts with high precision, accuracy and consistency, making them an important process in various industries.

Benefits of CNC machining

CNC machining work provides many benefits, including:

- High precision: CNC machines can produce parts with high accuracy and precision, making them ideal for industries requiring complex and detailed designs.

- Improve efficiency: CNC machines can run continuously, reduce production time and improve efficiency.

- Cost-effective: CNC processing reduces labor costs and minimizes material waste, making it a cost-effective solution for manufacturers.

- flexibility: The CNC machine can be programmed to perform various operations, making it versatile and flexible.

Services provided by CNC processing manufacturers

CNC processing manufacturers such as Light Light provide a range of services including:

- Five-axis CNC machining: This service can produce complex shapes and designs with high precision and accuracy.

- Custom precision machining: Manufacturers can produce custom parts according to specific designs and requirements.

- Post-processing and completion of services: Manufacturers can provide other services such as anodization, plating and polishing to enhance the appearance and durability of the final product.

Why choose excellent lighting for CNC machining jobs?

Light Light is a professional five-axis CNC processing manufacturer that provides advanced equipment and production technology. With a team of experienced professionals, great light can offer:

- High-quality products: Great Light ensures that all products meet the highest standards of quality, accuracy and accuracy.

- Quick turnaround time: Good Light can quickly produce custom parts, reduce production time and end pressing deadlines.

- Competing Price: Great Light offers competitive pricing, making it ideal for manufacturers and businesses.

in conclusion

In short, CNC machining work plays a crucial role in the production of high-precision parts and products. As demand for customized and complex products continues to grow, CNC processing manufacturers such as Light Light provide a range of services to meet the needs of a variety of industries. By choosing excellent light, manufacturers can benefit from high-quality products, fast turnaround times and competitive prices. Whether you need custom precision machining or post-processing and finishing services, Great Light is ideal for CNC machining needs.

FAQ (FAQ)

- What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to produce high-precision parts and products.

- What are the benefits of CNC processing?

The benefits of CNC machining include high precision, increased efficiency, cost-effectiveness and flexibility.

- What services do CNC processing manufacturers provide?

CNC processing manufacturers provide services such as five-axis CNC machining, custom precision machining, and post-processing and finishing services.

- Why choose excellent lighting for CNC machining jobs?

Great Light offers high-quality products, fast turnaround times and competitive prices, making it an ideal choice for manufacturers and businesses.

- Which materials can be used for CNC processing?

Most materials, including metal, plastic and wood, can be used in CNC processing.

- How long does it take to produce custom parts?

The production time of custom parts depends on the complexity of the design and the materials used, but excellent light can quickly produce custom parts to meet tight deadlines.