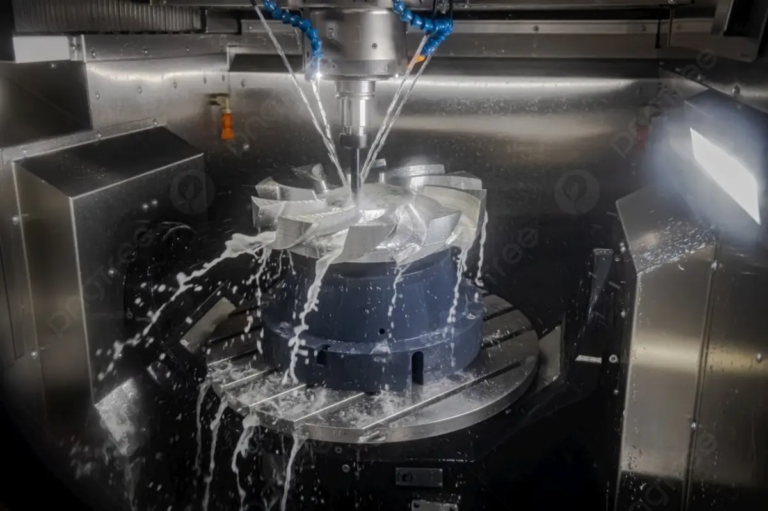

As a professional five-axis CNC machining manufacturer, Great Light has been providing first-class service to its customers. With advanced five-axis CNC machining equipment and production technology, the company has been professionally solving metal parts manufacturing problems. In addition to manufacturing capabilities, Great Light also offers one-stop post-processing and finishing services, allowing customers to quickly and efficiently customize their precision parts. But have you ever wondered how a company estimates the time it takes to complete a CNC machining project? In this article, we will dig into the world of CNC machining time estimates and explore the factors that affect it.

In order to accurately estimate the time required to complete a CNC machining project, several factors need to be considered. The first factor is the complexity of part design. Parts with complex geometry or functions require more time to be machined than simple designs. The type of material used is also a key factor, as different materials have different levels of hardness and difficult to process. Part size is also an important consideration, as larger parts require less time to machining.

Another factor that affects CNC machining time is the type of machining operation performed. For example, milling and turning operations have different machining times due to the different cutting tools and techniques used. The speed of cutting tools and feeding speed also play an important role in determining processing time. Faster spindle speeds and feed speeds can reduce machining time, but may also increase the risk of tool breakage or part damage.

The experience and skill level of the mechanic who operates CNC machines are also key factors in determining machining time. A skilled mechanic can optimize the machining process, minimize errors and reduce overall machining time. In addition, the maintenance and condition of the CNC computer itself will also affect the processing time. Well-maintained machines can operate at optimal levels, reducing downtime and improving yield efficiency.

Appropriately, the company uses advanced software and simulation tools to estimate the time it takes to complete a CNC machining project. The software takes into account part design, materials, machining operations and other factors to provide an accurate estimate of machining time. The company’s experienced mechanics also reviewed and optimized the processing process to ensure that the project can be completed efficiently.

In short, estimating the time required to complete a CNC machining project is a complex process and requires careful consideration of several factors. By taking into account part design, materials, machining operations and other factors, excellent light can provide accurate estimates and provide its customers with high quality precise parts. Whether you need customized precision machining services or one-stop post-processing and completion services, Great Light is the ideal partner to meet the needs of precision parts.

FAQ:

Q: How long does it take to complete a CNC machining project with a high light estimate?

A: Great Light uses advanced software and simulation tools to estimate the time it takes to complete a CNC machining project, taking into account part design, materials, machining operations and other factors.

Q: What factors affect the time it takes to complete a CNC machining project?

A: The complexity of part design, material type, part size, type of machining operations, speed and feed rate of cutting tools, experience and skill level of mechanics, and maintenance and condition of CNC machines all affect the time required to complete the CNC machining project.

Q: Can excellent lighting provide one-stop post-processing and organization services?

A: Yes, excellent lighting provides a one-stop post-processing and finishing service, allowing customers to quickly and efficiently customize their precision parts.

Q: Which type of material is an excellent light machine?

A: Great light can process most materials, including metal and other custom materials.

Q: How to get a quote for a CNC machining project?

A: You can contact Great Light directly to get a quote for a CNC machining project. The company’s experienced team will work with you to provide accurate estimates and provide high-quality precise parts.