In recent years, the demand for CNC processing services has grown and can be used with foreign materials. These materials, such as aluminum alloys, titanium and advanced ceramics, offer unique characteristics that make them ideal for certain applications such as aerospace, medical devices and high-performance components. However, processing these materials can be challenging and many manufacturers are struggling to find equipment and expertise that suits their needs.

CNC machining of foreign materials poses some challenges, including:

*Higher hardness: External materials are usually harder and more grinding than traditional materials, which can reduce cutting tools and reduce processing efficiency.

*Lower thermal conductivity: Many foreign materials have lower thermal conductivity, which can make it difficult for materials to cool during processing and prevent cutting tools from overheating.

* Lack of usability of processing equipment: External materials from machines often require specialized equipment, and many manufacturers may not be able to use this equipment.

*High Cost: Foreign materials are more expensive than traditional materials, and the cost of processing these materials is even higher due to the professional equipment and expertise required.

Despite these challenges, the benefits of CNC processing exotic materials make it a worthwhile investment for many manufacturers. These benefits include:

* Unique Features: Exotic materials provide unique properties such as high strength to weight ratio, corrosion resistance and high temperature resistance, which are critical for certain applications.

*Improved performance: The unique properties of foreign materials can improve the performance of the final product, making it more efficient, durable and reliable.

* Competitive Advantage: Manufacturers who can process exotic materials can differentiate themselves from their competitors and gain a competitive advantage in their market.

To overcome the challenge of CNC machining foreign materials, manufacturers can consider the following:

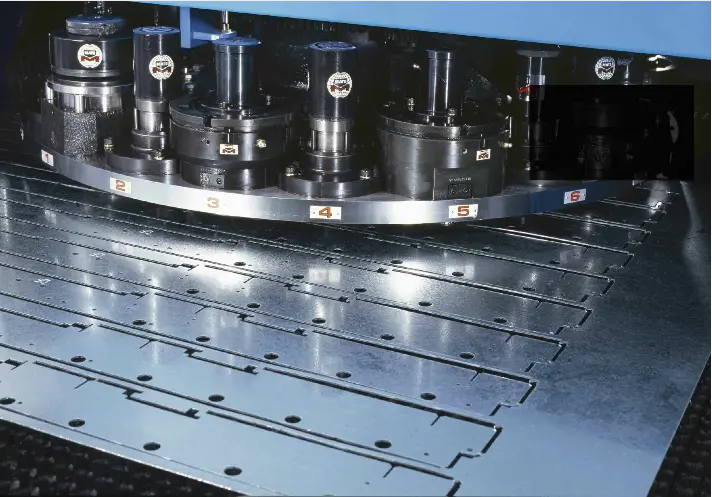

*Invest in professional equipment: Manufacturers can invest in specialized equipment designed for mechanical exotic materials, such as five-axis CNC machining centers or milling machines with advanced cooling systems.

* Work with experts: Manufacturers can work with experienced experts, such as professional contract manufacturers or research institutions.

*Develop new cutting technology: Manufacturers can develop new cutting technologies tailored specifically for exotic materials such as advanced coatings or cutting tool designs.

We already have advanced five-axis CNC processing equipment and production technology, and have extensive experience in processing a variety of foreign materials. We offer customized CNC machining services including cutting, milling and engraving, and we can provide one-stop post-processing and finishing services. Our expertise and equipment enable us to meet our customers’ unique needs and provide high-quality parts that meet their exact specifications.

in conclusion:

CNC machining of foreign materials is a complex process that requires specialized equipment, expertise and technology. However, the unique properties of these materials make it a worthwhile investment for many manufacturers. By understanding the challenges and opportunities associated with processing exotic materials, manufacturers can develop strategies to overcome these challenges and leverage the benefits these materials offer. Very smooth, we are committed to providing our customers with the best CNC machining services, we are committed to helping them achieve their goals and succeed in the market.

FAQ:

Q: What are the common challenges of CNC processing exotic materials?

A: Common challenges include higher hardness, low thermal conductivity, lack of usability of processing equipment, and high costs.

Q: What are the benefits of CNC processing of foreign materials?

A: Benefits include unique attributes, improved performance and competitive advantages.

Q: How can manufacturers overcome the challenge of CNC processing of foreign materials?

A: Manufacturers can overcome challenges by investing in professional equipment, working with experts and developing new cutting technologies.

Q: What kind of equipment do mechanical materials need?

A: Professional equipment such as a five-axis CNC machining center or milling machines with advanced cooling systems may need to be used in mechanical exotic materials.