The medical technology (MedTech) industry is a field that requires precision, accuracy and attention to detail in medical equipment and equipment manufacturing. Computer numerical control (CNC) machining is a key process for MedTech, involving the use of computer-controlled machines to manufacture medical components with high accuracy and accuracy. In this article, we will explore the role of CNC machining in MedTech, its application and benefits.

CNC machining is a subtractive manufacturing process that involves the use of various cutting tools to remove material from workpieces. This process is controlled by a computer program designed to generate a specific part or component. Due to the industry’s requirements for accuracy and accuracy, using CNC machining in MEDTECH is crucial. Medical equipment and equipment must meet strict regulatory requirements, and any defect or violation can have serious consequences.

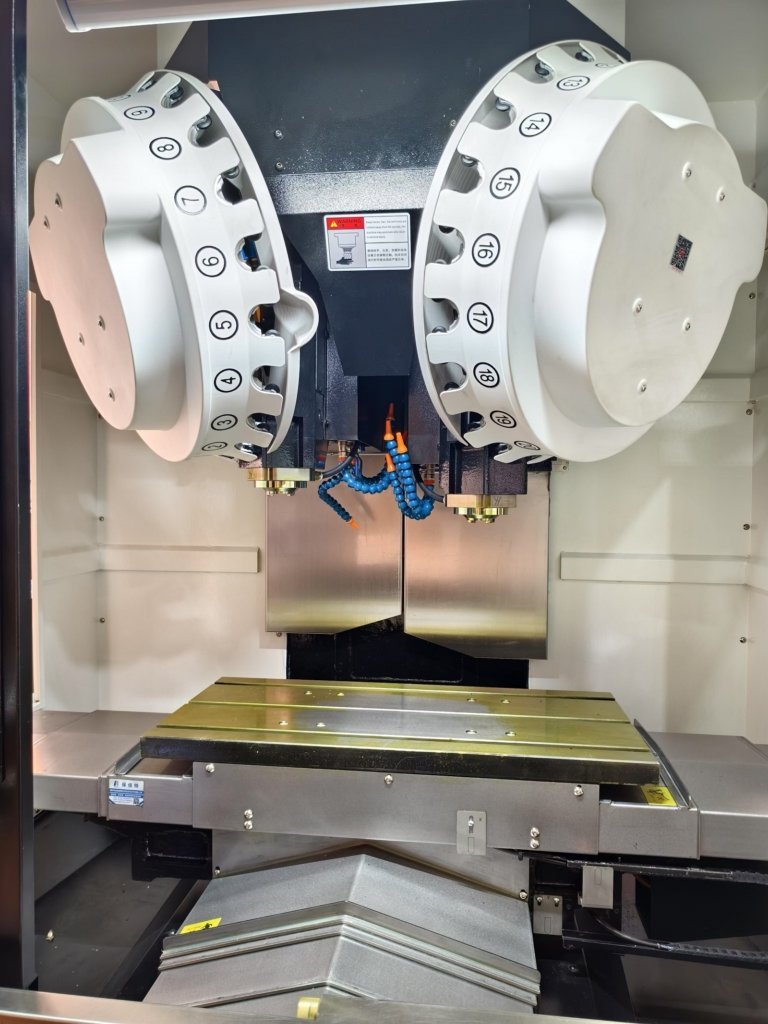

Light Light is a professional five-axis CNC machining manufacturer with advanced equipment and production technology that can solve metal parts manufacturing problems in MedTech. With the ability to quickly customize and handle most materials, Great Light’s five-axis CNC machining is the first choice for customized precision machining. Their one-stop post-processing and completion services ensure that medical components comply with required standards and regulations.

One of the main applications of CNC machining in MEDTECH is the manufacturing of implantable devices such as hip and knee replacements, dental implants and pacemakers. These devices require high accuracy and accuracy to ensure proper fit and functionality. CNC machining is also used to produce surgical instruments such as scalpels, tweezers and retractors, which must be manufactured in precise sizes and surface finishes.

Another important application of CNC machining in MedTech is the production of medical equipment such as MRI and CT scanners, ultrasonic machines and ventilators. These machines require complex components with precise dimensions and finishes, which can be achieved through CNC machining.

There are many benefits of CNC processing in MedTech. First, it can produce complex components in the form of high precision and accuracy, which is crucial in medical equipment and equipment. Second, CNC machining allows the use of a variety of materials, including metals, plastics and composites, which can be selected based on their properties and applications. Finally, CNC machining is an efficient process that enables the production of components quickly and cost-effectively, which is crucial in the Medtech industry, where time to market is crucial.

In short, CNC machining plays a crucial role in the MedTech industry, thus enabling high accuracy and accuracy of medical devices and equipment. With advanced equipment and production technology, manufacturers like Great Light can provide customized precise machining services that meet the required standards and regulations. With the continuous development of the MedTech industry, the demand for CNC processing services may increase, driving innovation and advancement in medical equipment manufacturing.

FAQ:

Q: What is CNC machining and how to use it in MedTech?

A: CNC machining is a subtraction manufacturing process that involves the use of various cutting tools to remove material from workpieces. In MedTech, CNC machining is used to manufacture medical components with high accuracy and accuracy, such as implantable devices, surgical instruments and medical devices.

Q: What are the benefits of CNC processing in MedTech?

A: The benefits of CNC machining in MedTech include high accuracy and accuracy, the ability to use multiple materials, and efficient production, which can enable rapid and cost-effective medical equipment and equipment manufacturing.

Q: What types of materials can be used in CNC machining in MEDTECH applications?

A: In CNC processing for MEDTECH applications, including metals, plastics and composites. The choice of materials depends on the specific application and required characteristics such as biocompatibility, strength and durability.

Q: How does CNC processing help in the production of medical equipment and equipment?

A: CNC machining helps in the production of medical equipment and equipment through the manufacturing of complex components with high accuracy and accuracy. This is crucial in MedTech, and any defect or irregularity can have serious consequences.

Q: What is the role of a professional CNC processing manufacturer?

A: Professional CNC machining manufacturers like Great Light play a vital role in MedTech by providing customized precision machining services that meet the required standards and regulations. They have advanced equipment and production technology to solve metal parts manufacturing problems and provide one-stop post-processing and finishing services.