Navigate the demand for modern manufacturing: Precision CNC machining in Arkansas

Arkansas is not only a natural state; it is increasingly becoming a hub for advanced manufacturing. Situated in a bustling industrial environment for companies that demand the highest levels of accuracy and repeatability Accurate CNC machining It is the cornerstone technology. For industries ranging from aerospace and defense to medical equipment, energy and cutting-edge robotics, the pursuit of making to strict specification components is ruthless. In Arkansas, manufacturers are struggling to address this challenge, leveraging the power of sophisticated computer-controlled machinery to deliver results that are simply impossible to achieve by manual methods.

Why Accuracy Is Crucial: Out of Dimensional Accuracy

The accuracy in CNC machining is far beyond the numbers on the blueprint. It includes:

- Excellent tolerance: The ability to repeatedly produce features in tiny size thresholds, usually drops to ±0.0001 inches (0.00254mm), or for critical applications.

- Upper surface surface: Implementing the required surface texture (RA, RZ) directly from the machine eliminates excessive post-processing and ensures optimal performance for parts with friction, sealing or aesthetic needs.

- Complex geometric implementation: Manufacture complex shapes, profiles, undercuts and freeform surfaces consistent and accurate, which is crucial for components such as aerospace engine parts, medical implants and fluid dynamics systems.

- Material integrity: Precise control of processing parameters ensures minimal heat-affected areas, prevents tool marking abnormalities, and retains inherent properties of challenging materials such as titanium, inconel or high-performance plastics.

- Repeatability and scalability: Once the CNC program perfects the precise components, it can consistently copy the quantity of that part, after batches, ensure interchangeability and reliability in the assembled product.

Meet Arkansas industrial needs

Arkansas has a diverse and demanding manufacturing base:

- Aerospace and Defense: Components that require extreme stress, temperature and environment, which fail zero tolerance. Think of turbine blades, flight control components, radar housing.

- Medical and Dental: Harsh biocompatibility, extremely high accuracy of implants and surgical instruments, and perfect surface surfaces to prevent bacterial composition.

- Oil, gas and energy: Valves, pump components, downhole tools exposed to high pressure, corrosive environments and harsh wear conditions.

- Automobile (performance/electric): Lightweight components require precise structural integrity, complex motor housing and thermal management parts for electric vehicles.

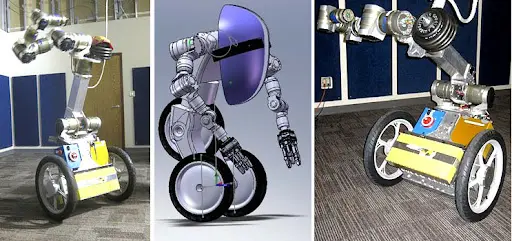

- Industrial automation and robotics: Highly accurate gears, actuator components and sensor brackets require tight seamless movement and control.

Accurate CNC machining is key to enabling these departments to conduct competitive innovation and competitive production both in state and globally.

Great Advantages: Improve Arkansas Accuracy

For enterprises seeking the pinnacle of precise CNC machining functions, Great Appear as a major solution provider. We understand that complex, highly resistant components are more than just parts. They are a key element in driving the performance, security and success of your product.

This is excellent to provide unparalleled precision for Arkansas demanding industries:

Advanced five-axis CNC mastery: Our arsenal includes the most advanced 5-axis CNC machining center. This function is Transformative accurate:

- Single-set manufacturing: Complex parts with complex geometry are required on multiple faces to be clamped in one clamp. This eliminates cumulative errors inherent in multiple fixture settings, greatly improving overall accuracy.

- Best tool access and control: 5-axis tool path control allows cutting tools to optimally approach the workpiece from almost any angle. This makes the inner corners clearer, smoother composite curvature and minimizes vibrations – which is crucial for precision and surface finishes.

- Reduce tool steps: Fewer setups and smarter tool paths simplify the process, making tolerant production more efficient and cost-effective.

Deep material expertise: Accuracy is not just a machine; it is about understanding the behavior of foreign materials and everyday materials under a cutting machine. Greatlight has extensive experience in precise machining of a wide range of materials, from common aerospace grade aluminum and stainless steel to challenge alloys such as titanium (Ti-6Al-4V), Inconel (625, 718), Tool Steels, Tool Steels and High-Performance plastics. This expertise translates directly into choosing the best speed, feed, tools and strategies to achieve accuracy without compromising the integrity of the material.

Comprehensive pre-production engineering: Achieving true accuracy requires expertise before the spindle begins. Our engineers rigorously analyze your design (DFM), propose optimizations for optimizing tolerance and cost-effectiveness, and carefully plan manufacturing strategies. We use advanced CAM software and simulation tools to predict and prevent potential problems.

Uncompromising quality integration: Accuracy is verified at each stage. Greatlight incorporates rigorous process inspections and utilizes high-precision measurement equipment including coordinate measuring machines (CMM), optical comparators and surface profile materials. This data-driven approach ensures that each section meets or exceeds your critical specifications before leaving our facility.

- True one-stop accurate completion: Meeting the final functional or aesthetic requirements often involves professional finishing. Greglight offers comprehensive post-processing services under one roof, including high criticality:

- Precise cleaning and degreasing

- Non-destructive testing (NDT)

- Enhanced surface treatment (anodized, passivated, electroplating)

- Exquisite heat treatment (relieves stress, aging, annealing)

- Accurate low pressure vibration finish

- Key Partial Marking (Laser Engraving, Electrochemical Etching)

This merger eliminates supplier handovers, simplifies logistics, and maintains strict control over the final quality of precision parts.

Conclusion: Accuracy is your strategic advantage

In the competitive environment of Arkansas manufacturing, precision is no longer a luxury. This is a basic requirement for innovation, reliability and market leadership. Working with CNC machining providers, it is crucial to be able to consistently deliver highly complex, ultra-proprietary components. Companies like Greatlight, equipped with advanced 5-axis technology, deep materials and engineering expertise, rigorous quality systems, and integrated finishes, can play a role in the success of Arkansas’ leading industry. They transform challenging designs into tangible, high-performance parts that meet the most stringent specifications while delivering efficiency and value.

Don’t let the limitations of machining functionality prevent your next project. Invest in Arkansas accuracy to ensure your products work perfectly, meet critical standards, and achieve outstanding results in demanding applications.

Be confident to meet your precise needs. Greglight turns complex demands into elaborate reality. Experience the expertise and advanced technology that focuses on difference. Customize your precision parts now at the best prices!

FAQ: Precision CNC machining in Arkansas

Q1: What tolerances can an accurate CNC store really have?

one: Although the achievable tolerances depend heavily on part size, geometry and material, modern precision CNC shops, especially with modern accuracy with 5-axis functionality, usually have tolerances of ±0.0005 inches (±0.0127mm) or tolerances on key features under optimal conditions. Maintain true position tolerances less than 0.001" Advanced equipment and processes can also be performed on large workpieces. Discuss your specific tolerance requirements for accurate assessment.

Q2: Is it always necessary to accurately 5-axis CNC machining?

one: Not always, but it’s Basic To achieve high accuracy on complex parts that require functions on multiple faces/surfaces. 3-axis machines are perfect for simple geometric shapes. The key advantage of 5-axis is that complex parts are completed in a single setup, greatly reducing setup errors and improving geometric accuracy. For demanding, complex components commonly found in aerospace or medical fields, it is often essential to require 5 axes.

Q3: My design involves complex curves/surfaces. Is this possible for CNC?

one: Absolutely. This is where 5-axis CNC machining shines. Advanced CAM software can generate complex toolpaths that continuously guide complex 3D surfaces inside and outside the cutter. These machines perform well in engraving complex organic shapes, turbine blades, impellers and molds while maintaining high precision.

Question 4: Can you work with my proprietary or hard-to-play alloy?

one: Yes. Reputable CNC machining stores in Arkansas often deal with challenging materials such as Inconel, Titanium, hardened tool steel and exotic atmosphere alloys. Their expertise lies in selecting the appropriate tools, managing cutting parameters (speed, feed, coolant) and using specialized techniques to effectively process these materials while controlling heat and retaining key characteristics to meet specifications.

Q5: I need tight tolerances, but the finish is <8 ra (micro plugin). How is this implemented?

one: To achieve both requires a multifaceted approach:

- Machine stiffness: Prevent vibration from causing endless chat.

- Advanced tool path: Used in CAM programming ensures smooth, continuous engagement.

- High-quality tools: Use carefully managed wear and tear to utilize a sharp precision ground cutting machine.

- Optimization parameters: Fine-tuning spindle speed, feed rate and cutting depth are crucial.

- Carefully fixed: Eliminates parts movement or distortion during machining.

- Complete the pass: Specially used to achieve final finish. Skilled mechanics use their expertise to effectively blend these factors.

Question 6: How do you ensure the accuracy of the parts you make?

one: Precision processing stores adopt strict quality assurance:

- First article check (FAI): Comprehensive dimensions and functional verification for the initial section of all specifications.

- Process Check: Measure key functions during processing.

- Advanced Metrics: 3D geometric verification is performed using calibrated highly accurate devices such as CMMs, surface validators to complete measurements and perform optical systems.

- Process control: Implement statistical process control (SPC) to monitor production operations for consistency.

- Detailed documentation: Provides a comprehensive inspection report with actual measured values.

Q7: What is the typical lead time for custom precision machining parts?

one: Delivery times vary widely based on partial complexity, quantity, material availability and store workload. Simple prototype parts can take several days, while highly complex components require custom fixes and extensive programming can take several weeks. High-profile stores such as Greatlight prioritize transparent communication and will provide realistic schedules based on your specific project requirements. Emphasizing speed without damaging quality is a key difference in competing stores.