Does Gold Electroplate Tarnish in CNC Machined Products?

1. Introduction

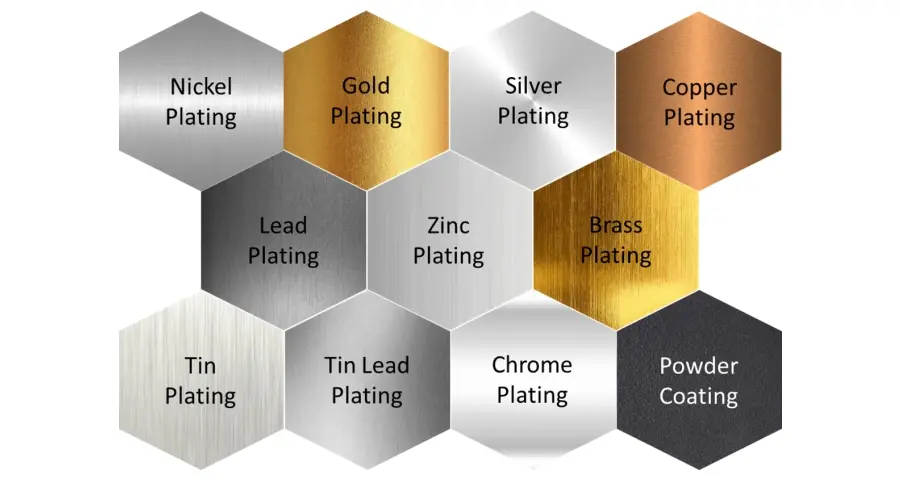

CNC machining produces high-precision parts that often require additional surface treatments to enhance their aesthetics, corrosion resistance, and electrical conductivity. One popular method is gold electroplating, where a thin layer of gold—typically between 0.1 and 5 microns—is deposited onto the machined surface. However, a frequent question among engineers and manufacturers is: Does Gold Electroplate Tarnish? This article explores the factors that affect the durability of gold electroplating on CNC machined products and provides expert insights into optimizing this process.

2. Understanding Gold Electroplating on CNC Machined Products

Gold electroplating is a post-machining process that deposits a layer of gold on metal parts. It serves several key functions:

- Enhanced Appearance: The lustrous finish improves the visual appeal.

- Corrosion Resistance: Gold’s inert properties protect the underlying metal from environmental damage.

- Electrical Conductivity: It ensures reliable performance in electronic and medical devices.

The longevity of the gold layer depends on various factors related to the plating process and the substrate itself.

3. Factors Influencing Gold Electroplate Tarnish

3.1 Coating Thickness

- Thin Coatings (<0.5 microns): These are more vulnerable to wear and oxidation, which may expose the underlying metal (such as copper or nickel) and lead to discoloration.

- Thicker Coatings (>2 microns): With increased thickness, the gold layer shows high wear resistance and can often maintain its appearance for 5–10 years without fading.

3.2 Substrate Material

- Copper/Brass: These materials can oxidize more readily. The micropores in a thin gold coating may allow the oxidation of copper or nickel to seep through, forming dark spots.

- Stainless Steel/Titanium Alloy: These substrates have higher chemical stability, which helps in slowing down the fading process of the gold layer.

3.3 Use Environment

- Wet or Acidic Conditions: Exposure to moisture and acidic environments accelerates oxidation, causing the gold plating to degrade faster.

- High-Frequency Friction: Mechanical wear from repetitive motion or friction can gradually remove the gold layer.

4. Causes and Solutions for Gold Electroplating Fading

When gold electroplating fades, it is usually due to one or more of the following causes. Below is a comparative table summarizing the primary fading causes and effective solutions:

| Fading Causes | Solutions |

|---|---|

| Coating is too thin | Increase the coating thickness to ≥1.5 microns or opt for hard gold plating to improve wear resistance. |

| Oxidation of the substrate | Use a barrier layer such as nickel or palladium to prevent oxidation and diffusion from the substrate. |

| Chemical corrosion | Avoid exposure to sulfur-containing substances (e.g., seawater, sweat) or apply a protective epoxy resin. |

| Mechanical wear | Optimize design to minimize friction or employ a wear-resistant coating (e.g., rhodium plating). |

5. The Synergistic Advantages of CNC Machining and Gold Electroplating

CNC machining and gold electroplating work hand in hand to produce superior components:

- Surface Quality:

CNC precision machining techniques like polishing and sandblasting reduce surface roughness to Ra 0.4 μm or less. This leads to a uniform substrate that minimizes coating defects. - Complex Geometric Compatibility:

With five-axis CNC machines, deep holes, inner cavities, and intricate features are accurately processed. Advanced electroplating methods, such as pulse electroplating, can then uniformly coat even the most complex geometries. - Material Adaptability:

CNC machining supports a wide range of substrates—from stainless steel and aluminum alloy to titanium alloy—each influencing the final durability of the gold layer.

6. Great Light’s Gold Electroplating Post-Processing Service

As an industry leader in CNC Machined Services, Great Light offers a comprehensive gold electroplating post-processing service designed to enhance both performance and longevity.

6.1 Process Control and Quality Assurance

- Coating Thickness Control:

Utilizing a micron-level electroplating process, Great Light can deliver customized gold coatings ranging from 0.5 to 5 microns based on application needs. - Multi-Layer Plating Technology:

By applying a nickel base layer (5–10 microns) beneath the gold surface, the process significantly enhances corrosion resistance.

6.2 Testing and Certification

- X-ray Fluorescence Spectrometry (XRF):

This non-destructive technique precisely measures the composition and thickness of the plating. - Salt Spray Testing (ASTM B117):

Rigorous testing ensures that the plating can withstand corrosive environments for at least 48 hours without fading.

6.3 Application Cases

- Medical Device Contacts:

Achieving 1.5-micron hard gold plating, these components have successfully passed over 10,000 plug-in and pull-out cycles without wear. - High-End Electronic Connectors:

With a 2-micron gold layer, connectors have maintained performance and appearance for 3 years even in 90% humidity environments.

7. How to Extend the Life of Gold Plating

Enhancing the durability of gold plating is achievable through several best practices:

7.1 Design Optimization

- Avoid Sharp Edges:

Sharp corners and stress concentrations can lead to plating cracks. Optimizing part design minimizes these risks. - Reduce Frictional Contacts:

A refined geometry can decrease areas where mechanical wear occurs.

7.2 Regular Maintenance

- Cleaning Protocols:

Regular cleaning with a neutral solvent can remove contaminants that might otherwise promote corrosion. - Chemical Avoidance:

Avoid contact with harsh chemicals that may trigger chemical corrosion.

7.3 Alternative Surface Treatments

- Rhodium Plating:

Offering a higher hardness (HV 800 vs. gold’s HV 200), rhodium plating is a viable alternative, though it comes at an approximately 40% higher cost. - PVD Gold Plating:

A vacuum deposition process that doubles the wear resistance, making it ideal for microelectronic components.

8. Conclusion

The longevity of gold electroplating on CNC Machined Products is influenced by key factors such as coating thickness, substrate selection, and the use environment. Through process optimization—such as using thicker coatings, incorporating a nickel barrier layer, and employing advanced post-treatment techniques—manufacturers can significantly extend the life of gold plating. With expert solutions from Great Light’s CNC Machined Services, you can achieve high-durability surface treatments tailored to your precision parts. Contact Great Light today to discover how their innovative approach can safeguard your products against tarnish while ensuring long-lasting performance.