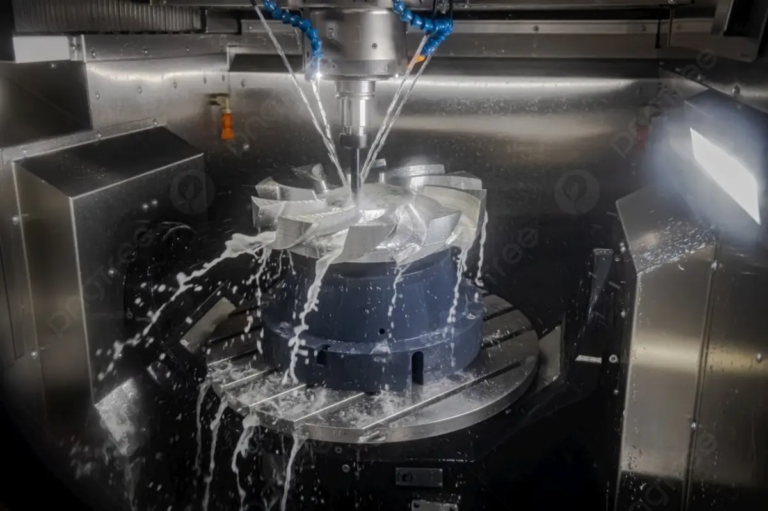

When it comes to CNC processing, especially when using materials such as aluminum, the clamping technology used can greatly affect the quality and accuracy of the final product. Aluminum is a relatively soft and stretchable metal that needs to be carefully treated to prevent damage during processing. In this article, we will dig into the world of CNC aluminum fixture technology, exploring various methods and best practices to ensure that your aluminum parts are processed accurately and cared for.

Learn about CNC aluminum clamps

CNC machining involves the use of computer-controlled machinery to accurately cut and shape materials. Due to its versatility, strength to weight ratio and corrosion resistance, aluminum is a popular choice for many applications, from aerospace to consumer electronics. However, its softness means that it can easily deform or damage if it cannot be properly secured during processing.

Clamping technology for CNC aluminum processing

Several clamping techniques are usually used in CNC aluminum processing, each of which has its own advantages and precautions:

Mechanical fixtures: This is one of the most traditional and widest approaches. It involves the use of fixtures or vises to physically secure the aluminum parts in place. Mechanical fixtures are direct and cost-effective, but may leave marks on the workpiece or distort it if too much force is applied.

Vacuum fixture: This technology uses a vacuum meter to secure the aluminum parts in place. Vacuum clamps are particularly useful for machining thin or delicate parts because they exert even uniform pressure across the entire surface, minimizing the risk of distortion. However, it may not be suitable for parts with complex geometries or parts that require high clamping forces.

Magnetic clips:For ferromagnetic aluminum parts (although aluminum itself is not, some aluminum alloys can be), magnetic fixtures provide a cleaning and effective way to protect the workpiece. This method is ideal for repetitive tasks and can greatly reduce the setup time.

- Adhesive clamping: This involves temporarily bonding the aluminum section to the processing table using a specialized adhesive. Adhesive clamping is ideal for machining operations that require high precision and minimal distortion such as milling or drilling. After processing, adhesive can be easily removed without damaging the parts.

Best Practices for CNC Aluminum Fixtures

- Make sure to be clean: The clamping surface and aluminum section must be clean and free of debris to obtain a safe fixation and prevent scratches or other forms of damage.

- Choose the right fixture: The clamping method and equipment should be selected according to the specific requirements of the part being processed, including its size, shape, material and operations to be performed.

- Monitoring fixtures: Applying proper clamping force is crucial. Too little force can cause partial movement during processing, while too much force can cause distortion or damage.

- Consider parts design: The design of the aluminum part itself can affect the choice of clamping technology. Design considerations, such as optimization of clamping points or part geometry, can simplify the machining process.

in conclusion

CNC aluminum fixture technology is a key aspect of precision machining, which directly affects the quality, accuracy and completeness of the final product. By understanding the different clamping methods available and following best practices, manufacturers can optimize their processing processes, reduce errors and increase productivity. Whether through mechanical, vacuum, magnetic or adhesive clamping, choosing the right technology for specific requirements of the aluminum section ensures high quality results and meets the requirements of precision and reliability of modern manufacturing.

FAQs (FAQs)

Q: What is the most common fixture method for CNC aluminum processing?

- A: Mechanical fixtures remain one of the most widely used methods due to their simplicity and cost-effectiveness.

Q: How to prevent damage from aluminum parts during clamping?

- A: Ensure that the clamping surface is clean, use appropriate clamping force, and take into account the design and material characteristics of the parts.

Q: Are vacuum fixtures suitable for all types of aluminum parts?

- A: No, vacuum fixtures are best for thin or delicate parts. Parts with complex geometry or requiring high clamping forces may not be ideal for vacuum fixtures.

Q: Can all aluminum alloys be clamped with adhesive?

- A: Adhesive clamping can be used in most aluminum alloys, but the choice of adhesive and clamping method should be evaluated based on specific alloys and processing operations.

- Q: How often should CNC fixture equipment be maintained?

- A: Regular maintenance of CNC fixture equipment is crucial. Frequency depends on usage, but should be performed at least quarterly to ensure accuracy and security.