The University of Cambridge defines biomimicry as“The practice of imitating natural processes in engineering and industrial design”. Although it may seem contradictory to relate technological progress to the natural world, this approach is actually driven by the growing recognition among engineers and scientists that nature often provides the best design solutions. Additionally, with the development of 3D printing technology, these complex designs have become feasible, unlike the limitations of subtractive technology. That’s why we decided to explore a few projects combining 3D printing and biomimicry from the list below to better understand how additive manufacturing allows us to bring these optimized models to life.

Earth Moc: Innovating through biomimicry

3D printed shoes are no longer a novelty: big brands like Adidas, New Balance and Nike use additive manufacturing to create their models. However, that doesn’t mean the innovation stops there. In addition to 3D printing, some designers are integrating bionics to develop more efficient solutions, as shown by the Earth Moc project. Designed by Daniel Shirley for Sintratec’s 2022 3D Printed Shoe Design Competition, the shoe is inspired by the intertwining of tree roots and vines to provide maximum comfort and flexibility. The designers hope that this lightweight TPE shoe can be used as a recovery shoe after hiking or even light exercise.

AguaHoja Pavilion

The AguaHoja Pavilion is located in San Francisco. It measures 5 meters high and has a complex “totem” shaped structure. This ambitious creation is the result of a collaboration between Neri Oxman, The Mediated Matter Group and Stratasys. Inspired by nature, the pavilion’s design incorporates a series of objects made primarily from organic materials and shaped by water. An additively manufactured frame using a Stratasys F900 3D printer supports the whole, keeping each individual component together. The project also includes an architectural proposal for an environmentally friendly melamine glass structure. “We needed to safely inhibit melanin-producing structures without compromising the ability to promote visual detail at all levels,” explains Neri Oxman.

The combination of fashion, technology and nature

American designerZac Posen made a splash at the 2016 Met Gala with his 3D printed artwork. In collaboration with GE Additive and Protolabs, he used additive manufacturing technology to design a dress, a corset and various accessories that will be worn by some of the stars of the evening. The dress worn by Zac Posen for Jourdan Dunn is inspired by the shape of a rose. He created a structure made up of 21 3D printed resin petals, each measuring around 50 centimeters long and weighing around half a kilo. Actress Nina Dobrev wears a translucent bra 3D printed using SLA Solutions, designed to give a glass effect reminiscent of flowing water. In total, it takes more than 200 hours to produce these parts in the German Protolabs factory.

“Tower of Life”: a building inspired by bionics

Designed and proposed by Built by Associative Data, the “Tower of Life” is an innovative architectural project in Dakar, Senegal, that combines eco-efficiency with traditional African design. The structure uses advanced 3D printing technology combined with a local biodegradable clay membrane. This helps reduce the environmental impact and construction costs by limiting the use of transported materials. Inspired by biomimicry, the Tower of Life acts as a positive energy system that manages resources, water and air while maintaining the microclimate with minimal emissions. The design imitates natural forms and functions as a closed-loop system, respecting local ecological conditions and contributing to the sustainable development of the city.

spiral shark intestine

Inspired by the spiral design of shark intestines, University of Washington researchers are using3D printing has developed a simplified bionic model, a design that slows the movement of food and efficiently guides it downward through gravity and peristalsis. The project involved creating soft, flexible structures that mimic these intestines to see how their unique design promotes unidirectional flow of fluid. This bionic method focuses on studying the impact of the radius and thickness of the 3D printed coiled tube on fluid dynamics. Ongoing research suggests that these findings could have important applications in soft robotics, medical and microfluidic devices, and industrial piping.

Safer helmet with mesh construction

3D printing makes it possible to imagine lattice structures directly inspired by nature: they actually resemble bee nests. Their design is very intelligent because it allows material to be placed only where necessary, thus optimizing the final weight of the part. This is a particularly interesting point in the world of sport, and especially when it comes to protective equipment. With the help of 3D printing and bionics, some players have imagined a bicycle helmet that is lighter, more durable, more comfortable and, above all, personalized. This is the case of KAV Sports and even HEXR who, thanks to additive manufacturing technology, have imagined a helmet that better absorbs impacts: it is 26% safer than traditional helmets. We can also cite American football and the company Vicis Enhanced, whose helmets feature 3D printed pads inspired by honeycombs. The use of 3D printing can reduce the impact of head contact with the ground by up to 7%.

HEXR Truss Frame Helmet (Image Source: HEXR)

Volvo and its3D printed living dam

In Australia, parts of the Sydney Harbor coastline are protected by sea walls, harming the habitat of marine species and forcing them to seek refuge elsewhere. To restore coastal ecosystems, Swedish automaker Volvo partners with the Coral Reef Design Laboratory at the Sydney Institute of Marine Science(SIMS) and North Sydney City Council have teamed up to launch a conservation project. Together, they developed and 3D printed concrete tiles inspired by the roots of local mangroves. The tiles are installed over the existing sea wall, creating cavities that serve as habitat for various marine species, including oysters, fish and algae. This initiative has helped reintroduce marine life to the Sydney coast and restore the fundamental balance of coastal ecosystems.

bionic:3D printed shoes spread seeds

The “Rewild the Run” project was initiated by British designer Kiki Grammatopoulos. These running shoes are designed to carry and spread seeds while running. How do they work? Kiki Grammatopoulos used the flexibility offered by 3D printing to create soles equipped with tiny hooks. As they run, runners collect plant matter scattered along the route. The shoes are inspired by a careful natural species: the bison, which uses its hooves and fur to spread seeds while creating paths for other animals to follow. The goal of Rewild the Run is to green the environment. As urban space expands, many natural habitats are destroyed or reduced. These shoes are seen as a solution to restore balance to the ecosystem.

Photo credit:Ecolosport

Pinarello imitates humpback whales to improve race car aerodynamics

Pinarello is a famous Italian bicycle manufacturer and a reference in the bicycle industry. Additionally, the Italian track cycling team is preparing to defend its title at the upcoming Olympics with Pinarello bikes. Pinarello always seeks to improve its performance, using the latest technologies and drawing inspiration from animal models. The frame is made from 3D printing and incorporates AirFoil sections as well as AirStream technology to improve the aerodynamics of the bike. The latter was developed in partnership with the University of Adelaide and NablaFlow and was inspired by the nodules found on the fins of humpback whales. These tubercles allow the whale to maneuver. On Pinarello bikes, these shapes are mounted on the seat post as AeroNodes, which reduces turbulence and improves aerodynamics.

Photo credit:Pinarello

3D printing and bionics: molds, adhesive models

Mussels are known for their ability to attach themselves to boats, thanks to the amino acid dihydroxyphenylalanine (DOPA) specific protein. Inspired by this natural adhesive property, researchers at Fraunhofer IAP and IGB have developed an antimicrobial adhesive for medical use. This adhesive can be applied to bones by 3D printing to facilitate the repair of joint injuries by promoting bone bonding. Additionally, it can be used to extend the life of existing implants, eliminating the need for surgical replacement.

Photo credit:Pixabay

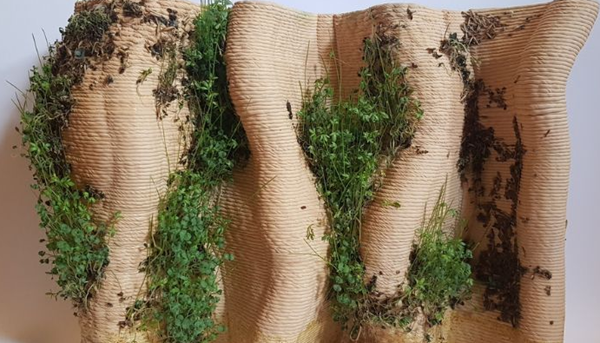

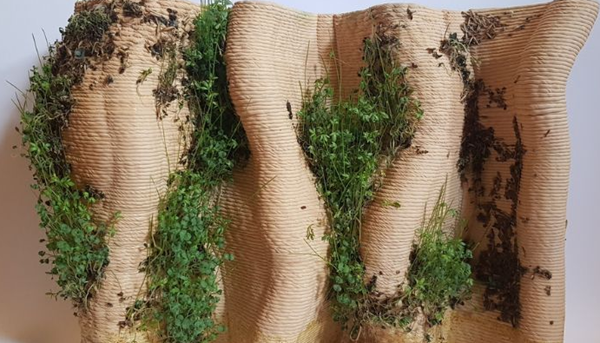

bionic wall

The “Bionic Wall” project aims to raise awareness of the current environmental situation and the importance of the relationship between ecology and architecture. This is a hydroponic ceramic wall created by 3D printing, originally developed as part of a master’s program at the University of Innsbruck in collaboration with Studio cera.LAB and exparch.hochbau. The walls are made up of complex ceramic structures fixed to metal frames. To create this structure, a 3D extrusion process with a 4mm nozzle was crucial, as traditional manufacturing methods were insufficient. The main objective of this wall is to combine modern technology, architecture and environmental awareness. Its porous surface encourages plant growth, thereby improving the climate in dense urban areas. In addition, the wall responds to its environment, promoting the greening of urban spaces while reducing ambient noise.

Photo credit:cera.LAB

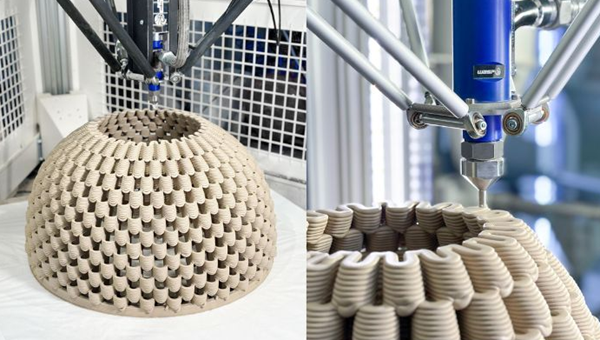

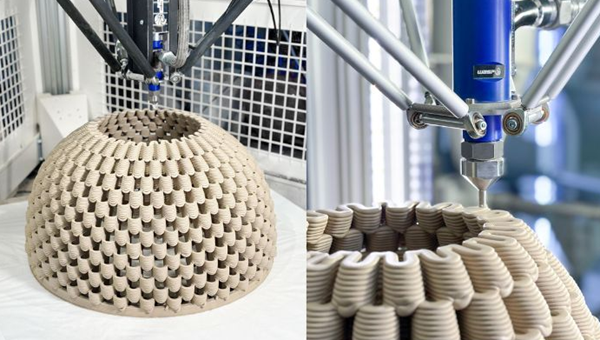

Paul·The Castelli lamp

last yearIn April, furniture company Paolo Castelli launched a 3D printed pendant light inspired by the organic structure of a honeycomb and designed to provide calming lighting. This series of lamps uses open-air ceramic 3D printing technology and is manufactured in collaboration with WASP, an Italian company specializing in large-format ceramic extrusion. Paolo Castelli highlighted the integration of sustainable practices in the production of these lamps, using natural ceramic materials and minimizing waste through the 3D printing process. Development begins with the creation of 3D models via CAD. Then, liquid deposition modeling (LDM) technology was adopted. What’s unique about this lamp is that it is air printed, allowing the shape to form naturally as it falls on itself. Paolo Castelli explains: “When the material is printed and dried, it folds spontaneously, forming a pattern of slits through which soft light can escape. This delicate design combines with the inherent properties of the material to provide a durable lighting system that invites you to enjoy relaxation. outdoor moments.

Photo credit:WASP

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.