CNC machining is a versatile manufacturing process that can be used to create a wide range of products from metal parts to rubber components. While metal processing is a perfect field, CNC machining of rubber is a more professional process that requires unique technology and considerations. In this article, we will dig into the basics of CNC-processed rubber to explore the benefits, challenges and best practices of using this versatile material.

One of the main advantages of CNC machining rubber is its ability to produce complex shapes and designs with high precision. Rubber is a flexible and flexible material that can be easily cut, drilled and shaped using CNC machines. This makes it an application that requires the production of seals, gaskets and other rubber components that require the use of complex designs or custom shapes.

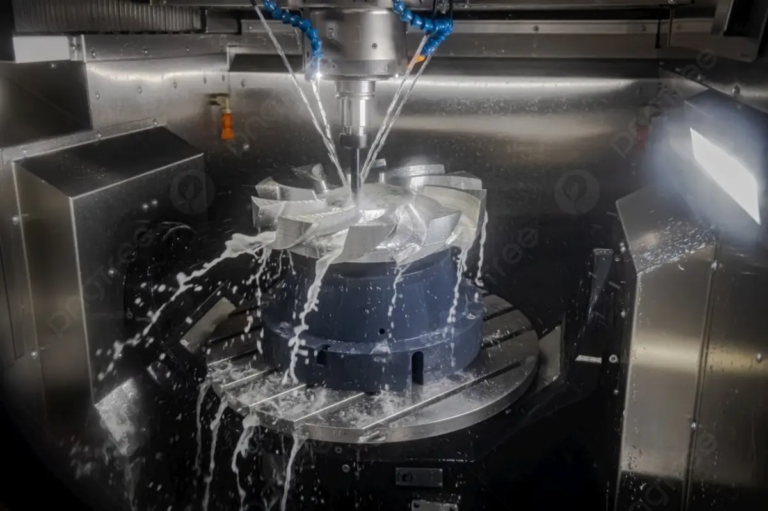

However, CNC machining rubber also presents some unique challenges. Rubber is a soft and flexible material that may be prone to deformation and vibration during processing, which may affect the accuracy and quality of the finished product. Additionally, rubber can be sensitive to heat and friction, which can cause it to melt or damage during processing. To overcome these challenges, CNC mechanics must use specialized tools and techniques, such as using coolant or lubricant to reduce heat and friction, and adopt advanced machining strategies to minimize vibration and deformation.

Another important consideration for CNC machining rubber is the type of rubber used. There are many different types of rubber, each with its unique properties and characteristics. For example, some rubbers are more flexible and flexible than others, while others may be more resistant to heat or chemicals. By understanding the specific properties and characteristics of the rubber used, CNC mechanics can optimize their machining techniques and tools for optimal results.

In addition to technical considerations, CNC processing rubber also requires careful attention to safety and quality control. Rubber dust and particles can be harmful to health, and proper ventilation and protective equipment are essential to prevent exposure. In addition, the finished product must comply with strict quality standards, including tolerances, surface surfaces and material properties. To ensure quality and consistency, CNC mechanics must adopt strict quality control procedures, including inspection and testing.

In short, CNC machining rubber is a complex and professional process that requires careful attention to technical, material properties and safety considerations. By understanding the benefits and challenges of CNC machining rubber, and using advanced tools and technologies, manufacturers can produce high-quality rubber components accurately and accurately. Whether you are producing seals, gaskets, or other custom rubber parts, CNC machining is a versatile and effective manufacturing process that can help you achieve your goals.

FAQ:

Q: What types of rubber can be processed with CNC?

A: A variety of rubber types can be processed using CNC, including natural rubber, synthetic rubber and specialty rubbers such as silicone and Viton.

Q: What are the benefits of CNC processing rubber?

A: The benefits of CNC machining rubber include high precision, flexibility and customization, as well as the ability to produce complex shapes and designs.

Q: What challenges does CNC face in processing rubber?

A: Challenges in CNC machining rubber include deformation and vibration, heat and friction, and material variability, which may affect the accuracy and quality of the finished product.

Q: What safety precautions are needed for CNC processing rubber?

A: Safety precautions include proper ventilation, protective equipment and careful treatment of rubber dust and particles to prevent exposure.

Q: How to ensure the quality and consistency of CNC-processed rubber parts?

A: Quality and consistency can be ensured through strict quality control procedures (including inspection and testing) and careful attention to processing techniques and material properties.