Transparency is not only aesthetics in the production of parts, but also necessary in certain cases.3D printing and flexibility in design, materials and process allow you to create parts with transparent effects. However, this task can be difficult because the fundamental principle of technology, the superposition of layers, creates spaces that light cannot pass, allowing debris to obtain a translucent effect. Glass is the material of choice to make transparent parts and becomes a viable solution for 3D printing. However, some plastics can reach a transparent effect. We will focus on this last material.

Before diving into details, it is important to distinguish between transparent and translucent effects. A transparent room allows more light to pass without obvious distoming, allowing you to see easily through the room. The translucent fragments allow the light to pass, but they will disperse, that is to say that we can recognize the forms, but the image you see through the fragments is not completely clear. In order to pass3D printing reaches different degrees of clarity, and we will analyze two technologies compatible with transparent plastic materials, the factors that must be taken into account for each technology and related applications.

Technology to create transparency

Resin -based process

When you think about transparencyWhen 3D’s printing, the first thing that comes to mind is to use a resin -based process. Photopolymerization (SLA, DLP) is one of the ideal techniques for obtaining high transparency and high quality parts because the surface obtained is smooth and allows more light to pass. There are different transparent resins on the market, and their characteristics are suitable for different transparent optical applications. Formlabs Clear Resin for SLA printers, for example, is a resin that allows you to obtain parts close to the transparency of the glass with fine details without long follow -up.

In addition to these processes according to the use of heat sources and storage tanks, we can also add material jets. This technology specifically allows the use of several resins and combinations of different materials simultaneously. This allows the machine to be loaded with transparent resin and multiple transparency can be obtained on the same component. In addition, material sprays have excellent resolution and very smooth surfaces, which will improve the aesthetics of the parts.

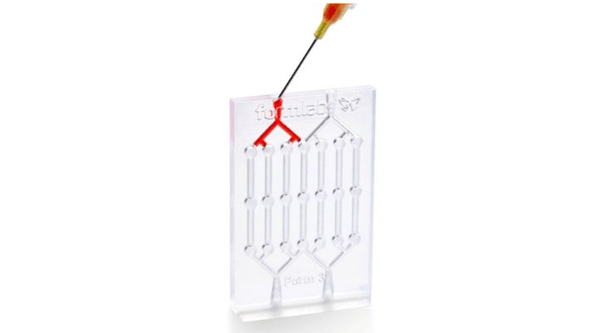

transparent3D printing is useful for studying microfluidic technology (image source: Formlabs)

However, the components of the resin have a common disadvantage of becoming yellow over time or to lose transparency after rinsing and drying. To avoid this, it is often necessary to apply the coating, polish and sand parts to make the surface as smooth as possible. In general, the combination of these technologies helps to improve transparency and brilliant.

Extrusion of materials

Cast iron deposit compared to the resin process(FDM / FFF) is a more economical and widely used technology, but performs less transparency. In fact, the deposit of the material in the continuous layer will disperse the light. In this case, the fragments obtained are quite translucent and opaque. Proofinent materials for transparent 3D printing using an FDM printer are PLA, polycarbonate and petg. Among these materials, PETG is best suited to transparent 3D printing due to its molecular structure which has a good transmittance of light.

To useFDM technology prints parts with transparent effects and requires that certain key parameters be taken into account. First, by reducing the height of the layer from 0.1 to 0.2, the visible lines can be minimized, resulting in a smoother and more uniform surface and can be polished with a transparent effect. It is also important to maintain the material that flows continuously to avoid bubbles and imperfections and print at a lower speed. The last aspect to consider is the filling of the parts. By choosing the least or no filling structure, the light can better pass through the components and obtain a more transparent effect. However, as mentioned above, the main limitation of the FDM in the printing of transparent components is the difficulty of completely withdrawing the lines in layers, even after a lot of post-processing, such as sanding and coating.

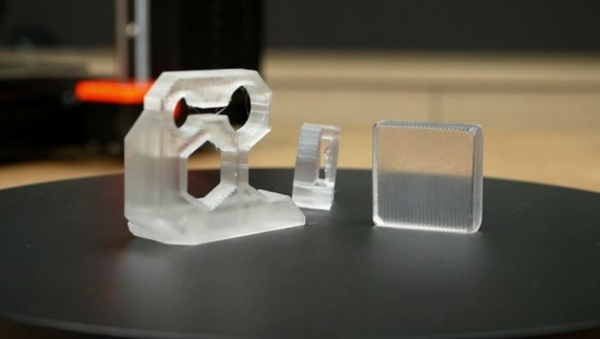

to useTransparent parts printed by PETG (image source: CNCKITCHEN)

transparent3D printing application

Transparent or translucent3D printed parts are appreciated not only for their aesthetics but also for their functionality. One of the most innovative uses is to develop prototypes that can observe the internal functioning of the mechanism so that the interaction between parts or mobile fluids is clearly visible. This feature is also particularly useful in microfluidic equipment and designs of the optical system. For example, the LED lamp housing and the light guide plate, its transparency facilitates the control of the passage of light. The most common use of transparent 3D printing is to decorate the elements. In fact, 3D printing of translucent or transparent components allows designers to create unique works with a surface or an effect similar to the glass.

WithCamera with 3D printed lens (image source: Formlabs)

Transparency of 3D printing is also highly sought after in the medical field, in particular to make surgical models as realistic as possible. In fact, health professionals can see the patient’s precise anatomy in this way, such as seeing all blood vessels in an organ. They can better understand the potential risks during surgery and be more prepared. It is also a way to reassure the patient: by showing the patient a transparent anatomical model, he can better understand the internal dynamics of the body.

Consequently, transparent3D printing offers interesting possibilities for the design and manufacture of high optical clarity parts. The choice of technology and materials depends on the relevant project. In addition to these factors, the use of specific installation and post-processing techniques will also determine the transparency effect to a large extent.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.