On the machining center, various tools are respectively installed in the tool magazine, and the selection and placement of tools are carried out at any time according to the program. Therefore, standard tool holders should be used to quickly operate standard tools used in drilling and reaming. , expansion, milling and other processes. , precisely installed on the machine tool spindle or tool magazine. Programmers need to understand the structural dimensions, adjustment methods and adjustment range of the tool holder used on the machine tool, to determine the radial and axial. dimensions of the tool during programming. BT40 and BT50 series tool and rivet holders are the most widely used in our country.

1. Tool holders commonly used in machining centers

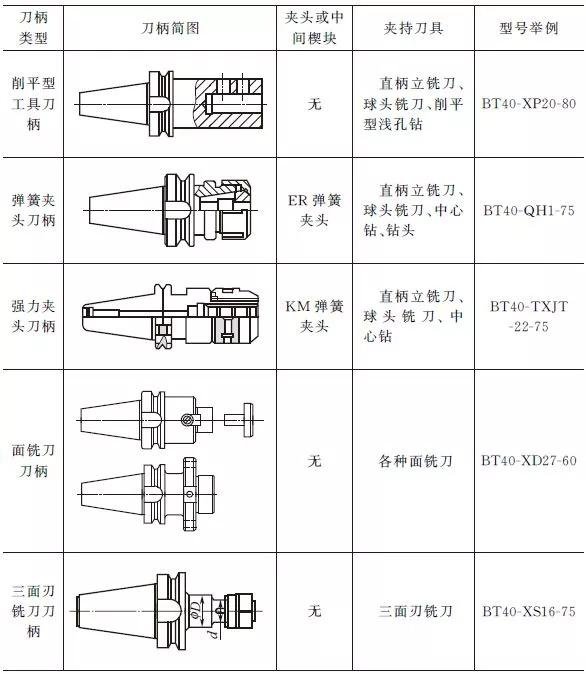

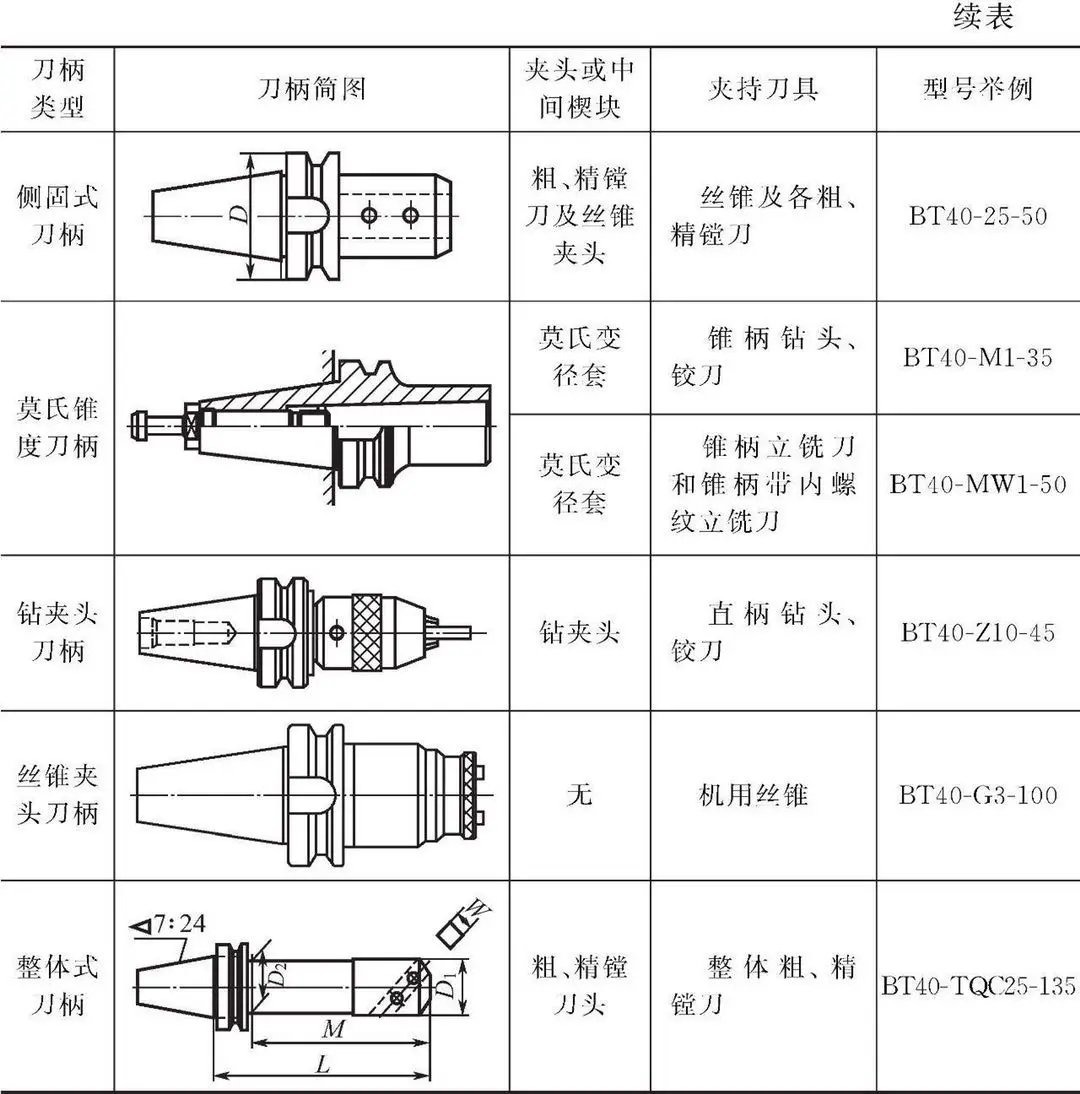

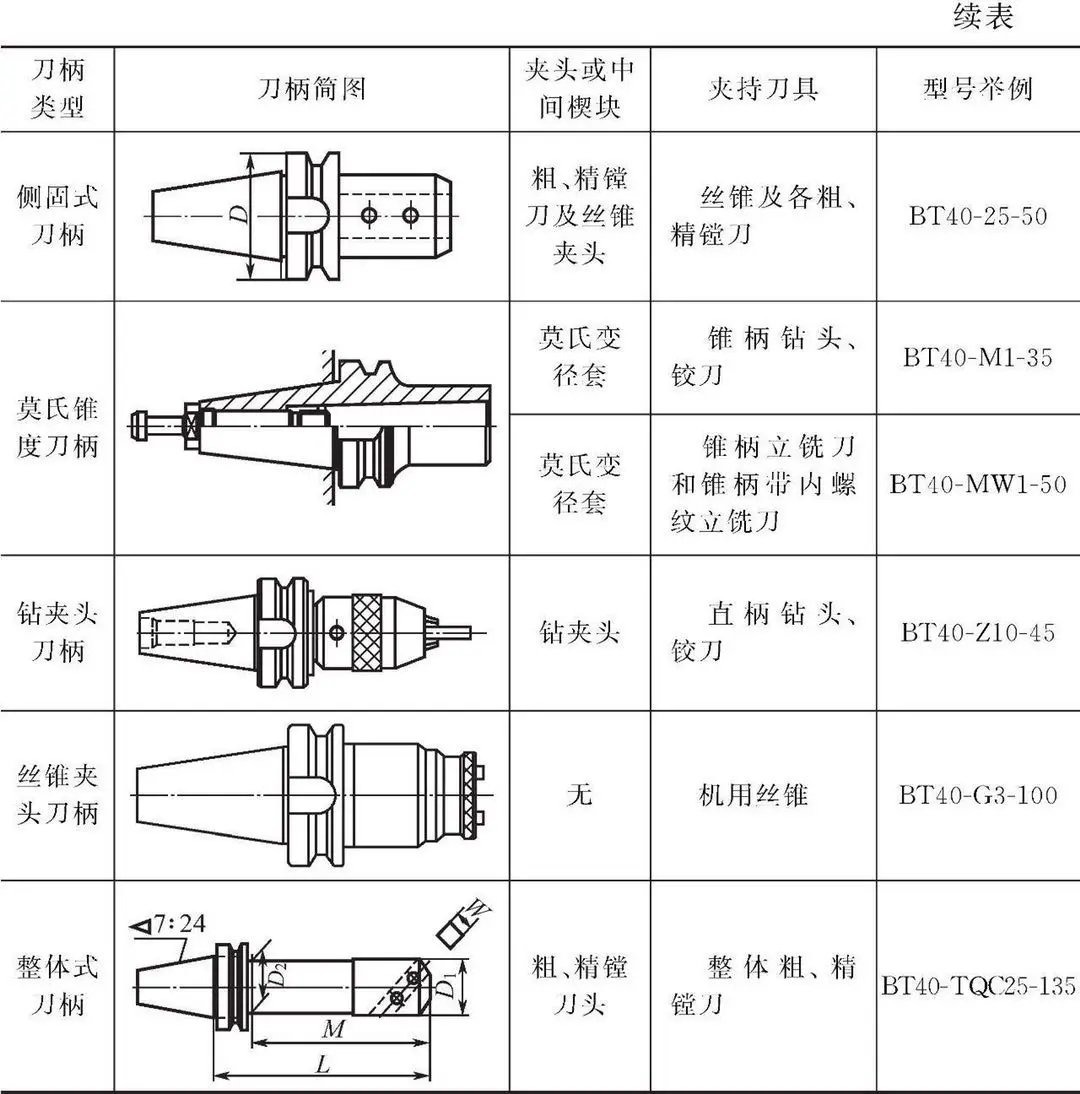

The types and application areas of tool holders commonly used in machining centers are shown in Table 1-4.

Table 1-4 Types and application areas of tool holders commonly used in machining centers

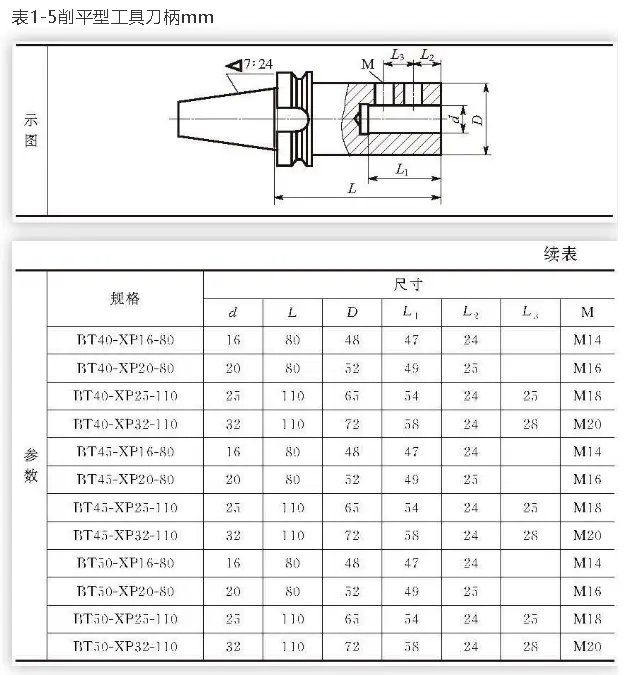

Common specifications of tool holders for machining centers

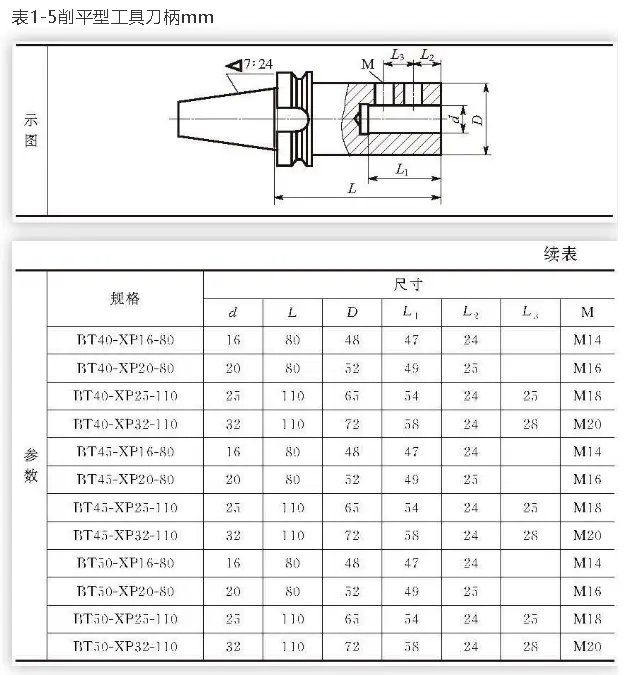

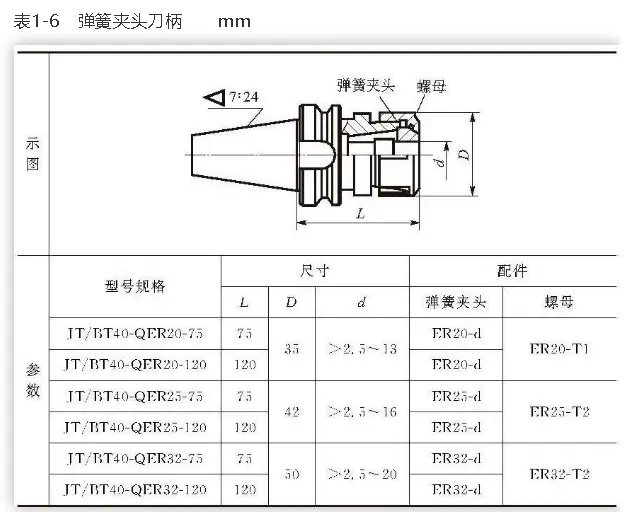

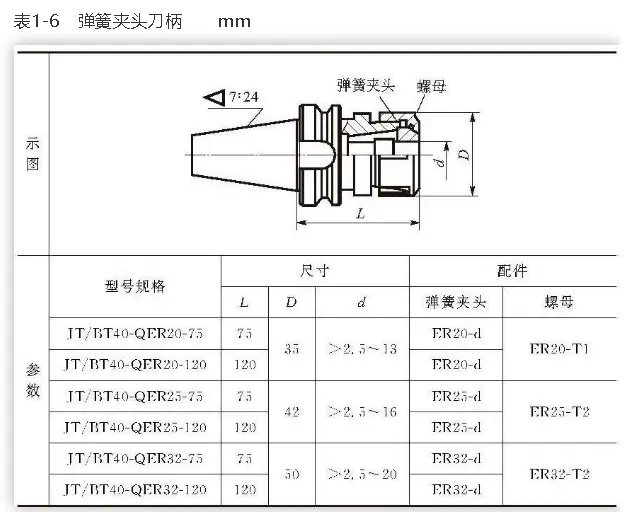

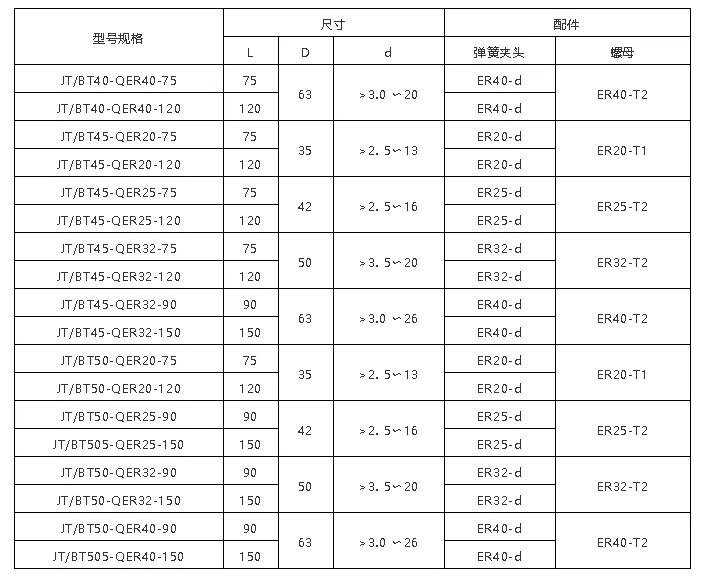

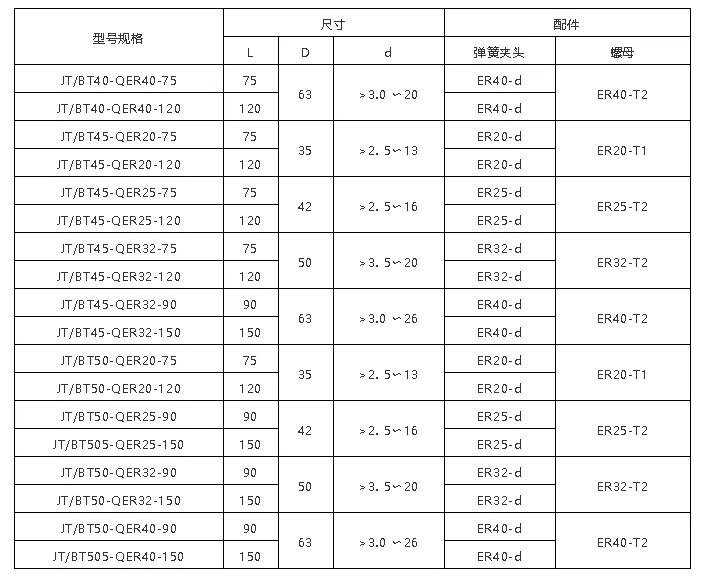

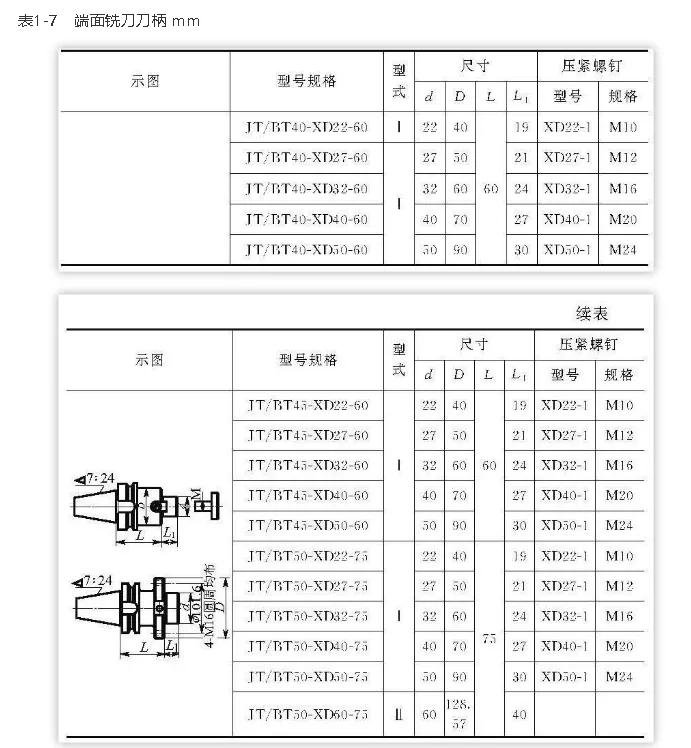

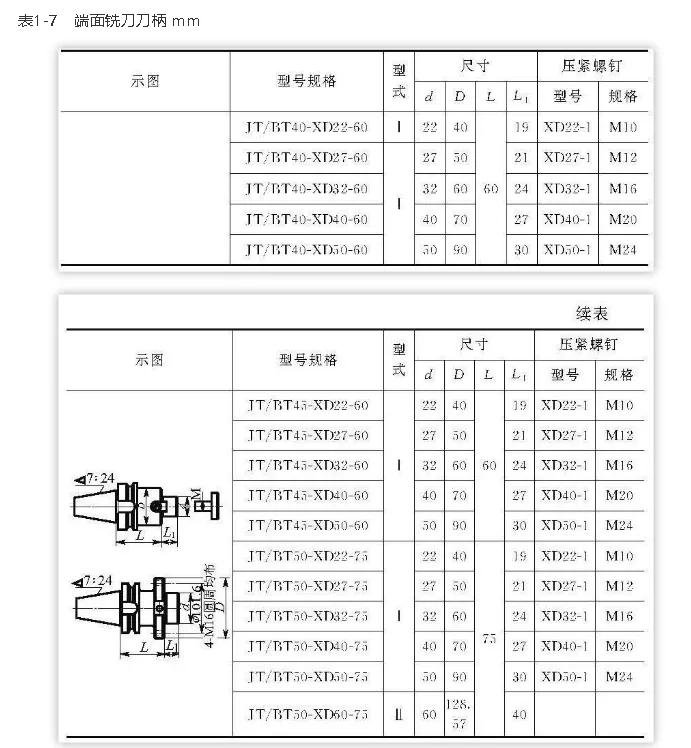

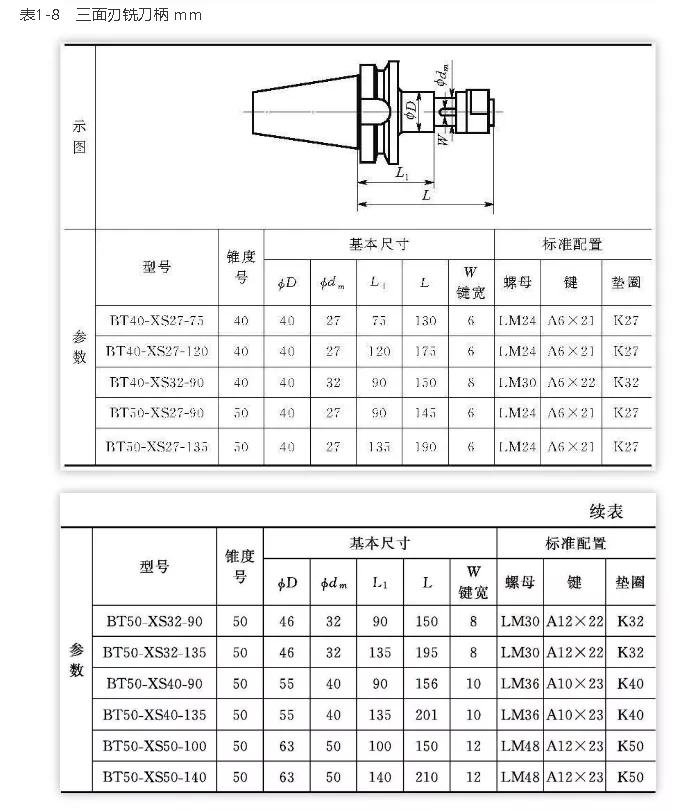

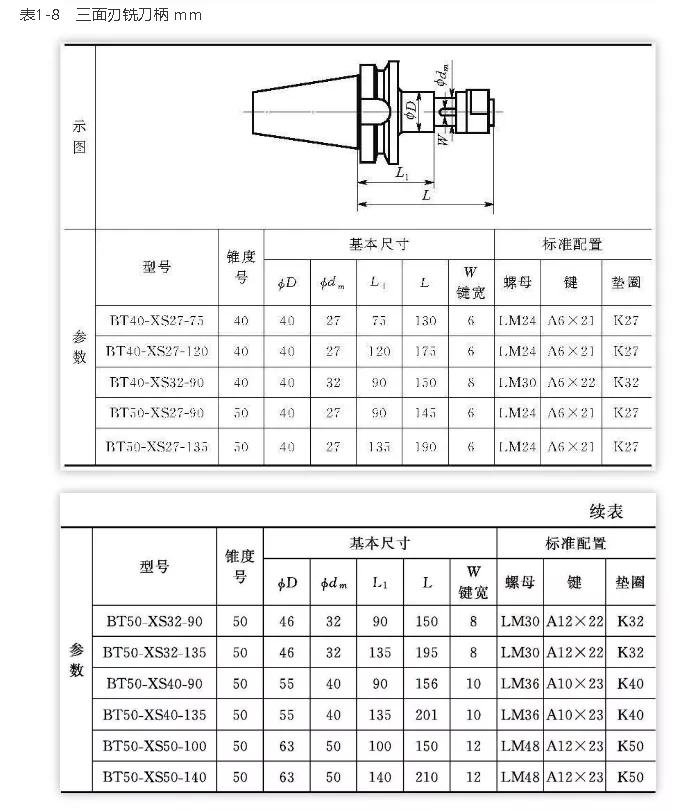

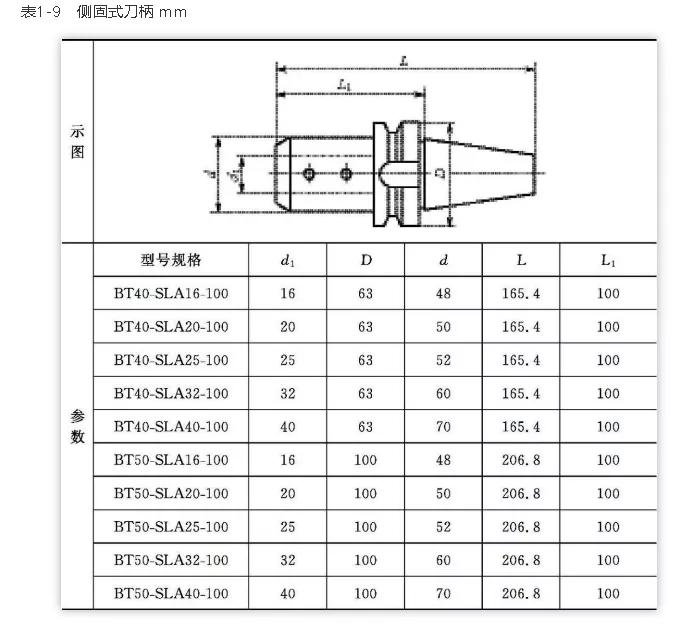

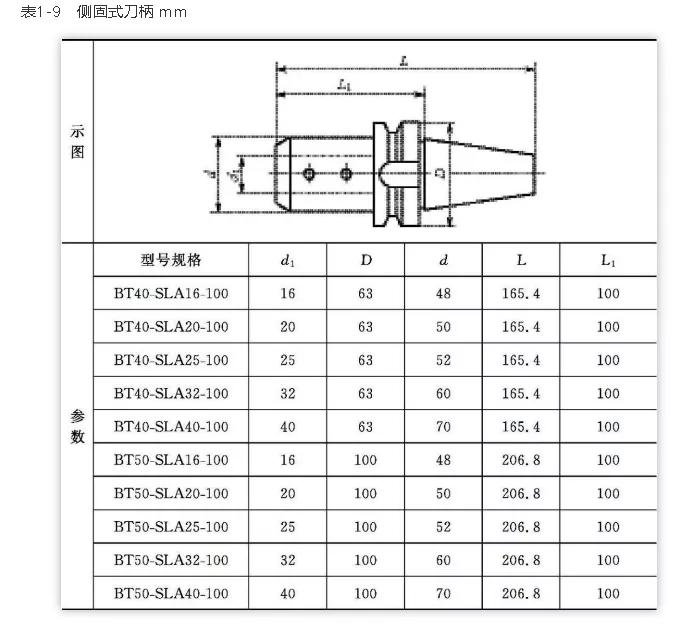

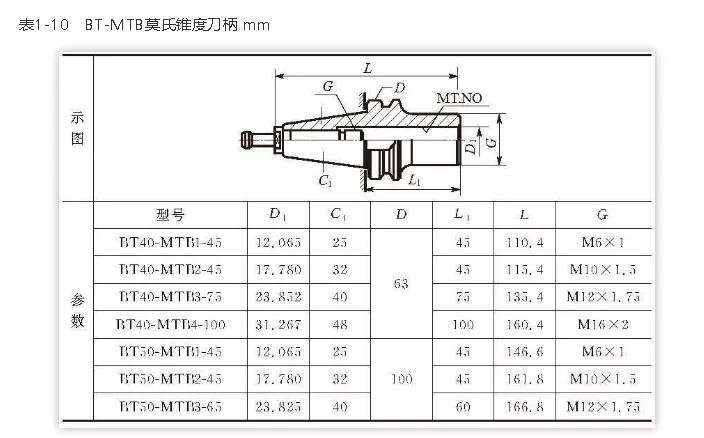

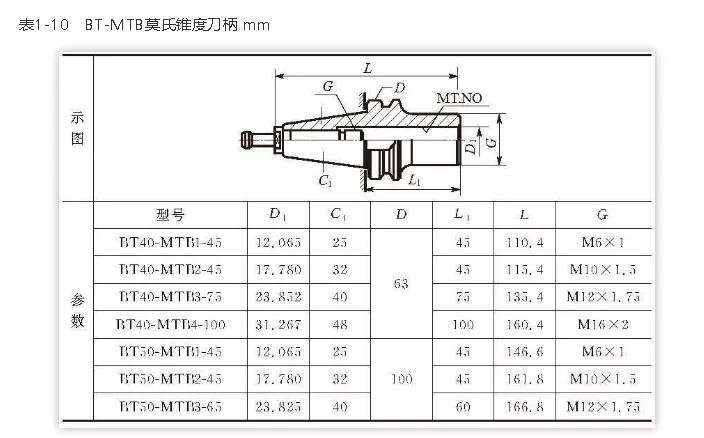

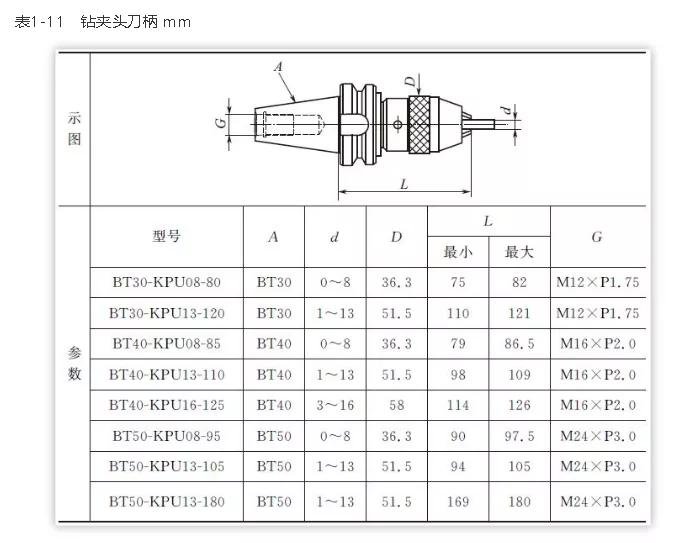

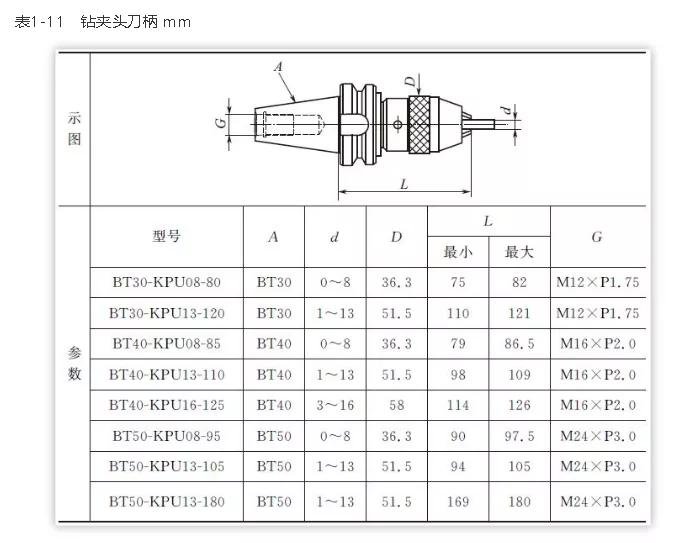

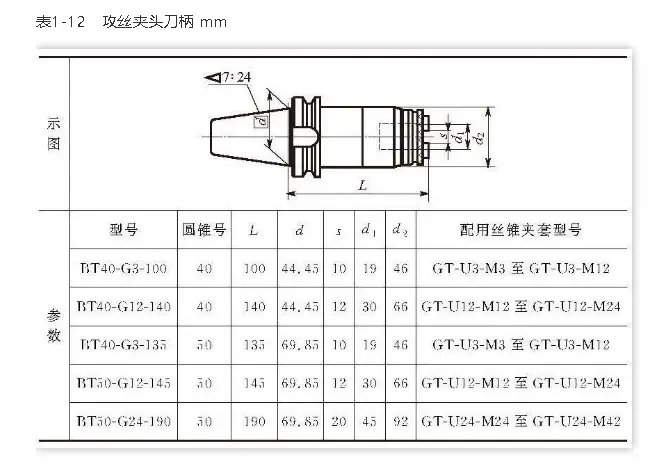

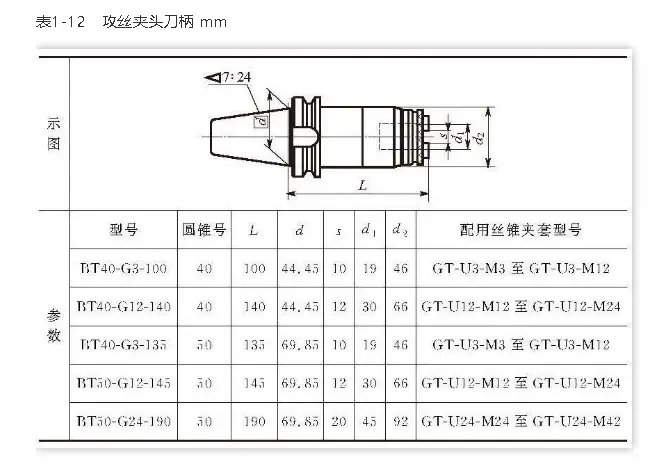

The specifications of tool holders commonly used in machining centers are shown in Table 1-5 ~ Table 1-12.

No tool rack system is perfect. Tool holders specifically designed for high-speed finishing operations often lack the rigidity and strength required for efficient machining, such as roughing of raw castings. In contrast, tool holders used for roughing operations often lack the dynamic balance necessary to enable smooth and rapid operation during finishing operations.

Additionally, the rugged design and bulk of a roughing tool holder can limit its ability to achieve thinner or deeper part features. And difficult-to-machine materials require tool holders with increased strength and rigidity. In addition, the vibration damping capacity of the tool holder and the coolant distribution capacity are also important selection criteria. Using the wrong tool holder can result in dimensional errors and scrapped parts, as well as excessive wear on the machine tool spindle, reduced tool life, and increased risk of tool breakage.

In non-critical work, a good quality, inexpensive tool holder can produce satisfactory results. However, in operations where repeatable accuracy is a must, especially where scrapping expensive parts reduces part profit margins, investing in high-quality, application-focused toolholders can prevent such unexpected losses at lower cost.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.