Today, we will take you by boat, but it is not an ordinary boat! In fact, it is a ship entirely held by a company in Dubai3D printed ship. Thanks to 3D technology, it can considerably reduce manufacturing time and thus improve productivity. In addition, the structure is made of recycled plastic. In this 3DEXPRESS, you will also be on the plane: a Polish airline has in fact chosen additive manufacturing to design the new armrests of its Boeing 737 seats.

Dubai3D print boat

As you probably know, the city of Dubai is planning to use additive manufacturing to build its infrastructure. This use also seems to extend to transport, more specifically the ship. Actually,3D underventive has just launched the first 3D printed ship in the city. It is called Cyberfinau, 10 meters long, 2.1 meters wide and 2.7 meters high, and is in recycled marine litter. Depending on the company, it took 6 days and 9 hours to manufacture the product (and traditional methods took 3 to 4 months). It can accommodate 10 people. The inventory 3D intends to accelerate the production of these ships – it can print 3D from 6 to 7 structures per month.

Boeing3D printed workforce from 737

Polish Airlines is a national airline in Poland, with theft destinations distributed in many places in the world. In its fleet, there are several Boeing737. If we are going to tell you about it today, it is because the economy class seats are now delivered with current hands printed in 3D. The airline has received 1,200 handrails in particular. Previously, they were made using more traditional methods, and their assembly steps affected the lifespan of the current hand. Its characteristic is that the hood is mounted on the frame molded by injection. But the cover often detaches from the frame, causing frequent ruptures. To solve this problem, Lot collaborated with Am Craft, which uses FDM technology and the ULTEM 9085 filament. The handrail has been completely redesigned to avoid these assembly steps and the risks mentioned above. The final handrail is not only more sustainable, but also faster to acquire, and airlines also eliminate the hassle of spare parts and storage.

Original Handreil;3D printed part; Two handrails printed 3D (image source: AM Craft)

Saeki’s major investment

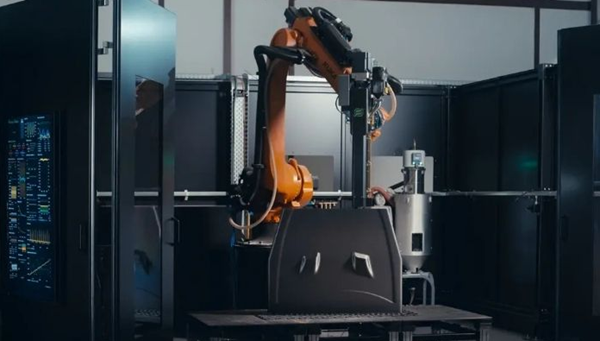

Swiss manufacturerSaeki is a manufacturer of large manufacturing machines that rely on 3D printing, CNC machining and automation, in particular in quality control. The company announced this week that it would invest $ 6.7 million to continue its growth. She also took the opportunity to present her new instant quote solution, highlighting the idea that all manufacturing stages must be as automated as possible. Andrea PerinSinotto, co-founder and CEO of Saeki, concluded: “The automation of the entire process of quotation to the final inspection will make it possible to produce advanced conceptions on a scale. Manufacturing with CNC machining and quality insurance provides the industry with innovative tools without restriction. . “”

Saeki’s machine (photo provided by: Saeki)

Made of kombucha3D printed biooink

National University of Sciences and Technologies of Seoul (A team of Researchers from Seoultech has developed an innovative biose based on nanocellulose extracted from Kombucha Scoby. This biomaterial acts as a support structure for cell growth and can be applied directly to damaged tissues using a digital biopen. By modifying the structure of the material and combining it with nanoparticles of chitosan and kaolin to improve its stability, which makes it suitable for 3D biopritis. Using a digital biopen, researchers can print high -resolution multilayer structures and directly treat complex wounds and deformations. This technology represents an important advance in the field of regenerative medicine because it can immediately repair tissues without the need for extracorporeal processes, which facilitates use in emergency and first aid situations.

Photo source:Seoultech

Q.BIG 3D has filed a record and seeks investors

With large format innovationThe 3D printing technology, the startup Q.big 3D has become one of the most promising startups in the 3D printing field in Germany. The situation went now and Bucknan’s young business has filed for bankruptcy. The reason is the difficulties of cash, because Q.BIG invested a lot of money last year, paving the way to the internationalization of the company. This objective is maintained and must succeed with the help of new investors. Pluta Rechtsanwalts-GmbH appointed a receiver to support the restructuring of Q.BIG 3D. “Commercial operations are continuing and we are now looking for investors for this innovative business,” said Bananyarli’s lawyer. The salary of these twenty employees will be guaranteed for the next three months.

Dennis Herman, founder of Q.BIG 3D (Photo source: Q.BIG 3D)

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.