The Art of Precision: China CNC Machining Factory Offers Custom Manufacturing with Up to ±0.05MM Tolerance

In today’s fast-paced manufacturing landscape, precision is key. To maintain a competitive edge, companies must prioritize accuracy and reliability in their products. This is where China’s CNC machining factories come in, offering custom manufacturing solutions with unparalleled precision. In this article, we’ll delve into the world of CNC parts custom manufacturing, exploring the benefits of partnering with a reputable China CNC machining factory, and highlighting the exceptional tolerances achievable with their cutting-edge technology.

The Benefits of CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process, where a computer-controlled machine tool moves along a predetermined path to remove material from a workpiece, resulting in a high-precision part. This technique offers numerous advantages, including:

- Accurate control: CNC machining allows for precise control over the manufacturing process, enabling the creation of complex geometries and intricate designs.

- Competitive advantage: By leveraging the benefits of CNC machining, companies can differentiate themselves from competitors, exploiting the precision and accuracy offered by this technology.

- Streamlined production: CNC machining’s computational control enables automated production, reducing labor costs and minimizing the risk of human error.

The Importance of Tolerance in CNC Machining

Tolerance refers to the acceptable range of variation in the size and shape of a manufactured part. In CNC machining, tolerance has a direct impact on the precision and quality of the end product. A close tolerance ensures a better-fitting part, with less material need to be machined away, resulting in cost savings and reduced production time. In contrast, a loose tolerance may lead to parts that do not fit as intended, requiring additional costly adjustments.

Meet the Tolerance Challenge with China’s CNC Machining Factory

China’s CNC machining factories have responded to the demand for precision manufacturing by developing exceptional tolerance capabilities, with some achieving a tolerance as low as ±0.05MM. This level of accuracy is only possible due to the factories’ commitment to technological advancements, rigorous quality control measures, and a relentless focus on customer satisfaction.

How China’s CNC Machining Factory Achieves Up to ±0.05MM Tolerance

To achieve such exceptional tolerances, China’s CNC machining factories employ a combination of cutting-edge equipment, experienced operators, and strict quality control processes. Some key factors contributing to their success include:

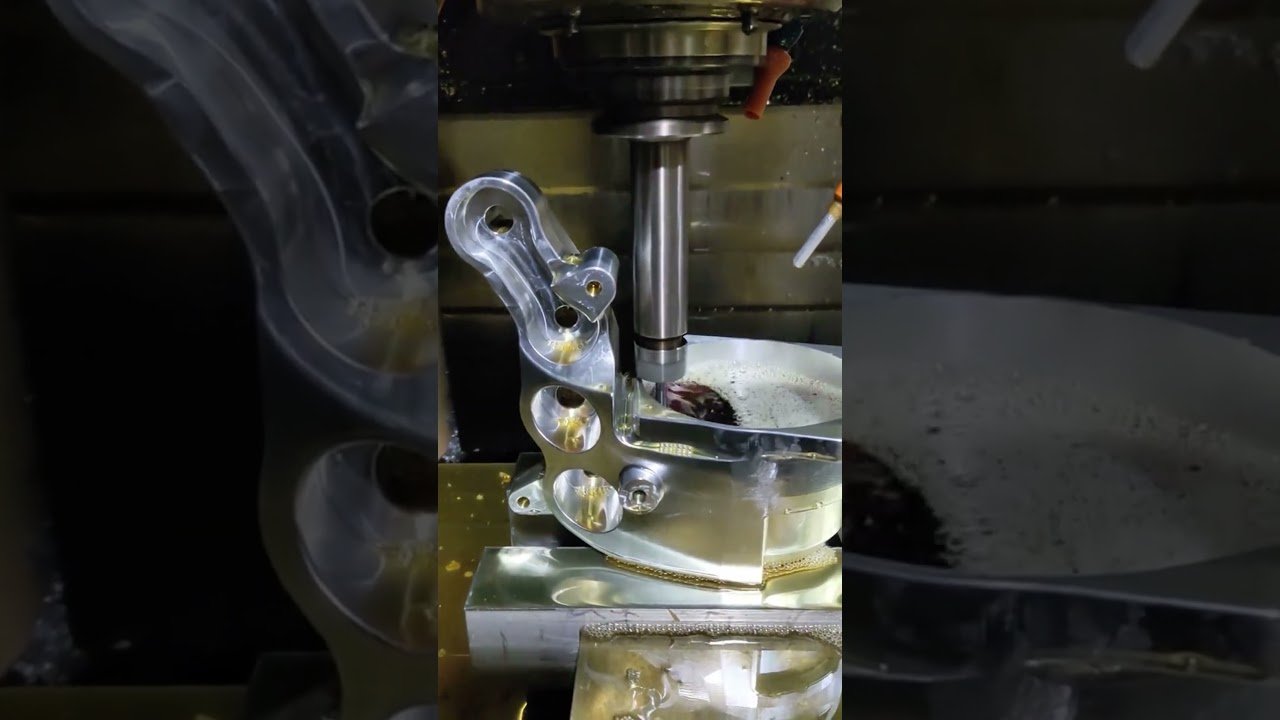

- State-of-the-art machines: China’s CNC machining factories are equipped with cutting-edge CNC machine tools, such as 5-axis machining centers, milling machines, and lathes. These machines provide increased precision, reduced vibrations, and improved surface finish.

- Operator expertise: Skilled and experienced operators are essential to ensuring accurate machining. China’s CNC machining factories boast highly trained staff, able to operate the latest machines with ease and precision.

- Quality control measures: A thorough quality control process is crucial to maintaining the highest standards of accuracy. China’s CNC machining factories implement strict quality control measures, including dimensional checks, surface finish evaluations, and material inspection.

- Material selection: The right material selection is critical to achieving the desired tolerance. China’s CNC machining factories choose from a wide range of materials, ensuring the optimal choice for each project.

Image: A comparison between ±0.05MM and standard industry tolerances

Case Studies: Where Precision Matters

The importance of precision in CNC parts manufacturing is evident in various industries, including:

- Aerospace Engineering: High-precision parts are critical in the aerospace industry, where minute tolerances can spell the difference between success and failure.

- Medical Devices: Medical devices, such as surgical instruments and implantable devices, require tight tolerances to ensure accurate function and minimize risk.

- Automotive parts: Automotive parts, such as gears, bearings, and engine components, demand precision to guarantee smooth operation and extend lifespan.

Conclusion

In today’s ever-evolving manufacturing landscape, precision is a decisive factor for companies seeking to maintain a competitive edge. China’s CNC machining factories have risen to this challenge, offering custom manufacturing solutions with unparalleled tolerances of up to ±0.05MM. By leveraging advanced technology, operator expertise, quality control measures, and material selection, these factories produce high-quality parts that meet and exceed customer expectations. Whether in the aerospace, medical, or automotive industries, precision is no longer a luxury, but a necessity. When precision matters, China’s CNC machining factories are the trusted partner to turn to.

Optimize your manufacturing process with us [Your Company Name] is a leading China CNC machining factory, dedicated to delivering precision parts with a tolerance of up to ±0.05MM. Our team of experts is committed to identifying the best manufacturing solutions for your unique requirements, ensuring your parts meet the highest standards of quality and accuracy. Contact us today to learn more about our CNC parts custom manufacturing services.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.