Prototype to Production LiDAR Hardware Companies: A Comprehensive Guide

The LiDAR (Light Detection and Ranging) industry is transforming rapidly through innovations in autonomous vehicles, robotics, and geospatial mapping. Transitioning from a LiDAR prototype to full-scale production requires meticulous planning, precision engineering, and a partnership with trusted prototype-to-production companies. In this guide, we delve into the step-by-step process for prototyping LiDAR hardware, explore cost factors and challenges, and outline what to consider when moving from concept to market-ready products. Whether you’re an emerging startup or an established enterprise, understanding these stages is essential to achieving cost-effective, scalable production.

How to Prototype a LiDAR Product

Step-by-Step Prototyping Process

- Conceptual Design:

The process begins with defining your LiDAR product’s specifications such as range, resolution, and field of view. Employ CAD software like SolidWorks or Fusion 360 to create a detailed 3D model of the LiDAR components, including optics, sensor housings, and mechanical supports. - Material Selection:

Selecting the right materials is crucial. For optical elements, choose between glass lenses for superior clarity or durable polymer alternatives that may reduce weight and cost. For housings, lightweight aluminum is ideal for prototyping, whereas titanium offers high strength for final production in high-stress applications. - Prototyping Methods:

- 3D Printing: Utilize 3D printing for rapid iteration, particularly for non-optical parts such as brackets or structural enclosures.

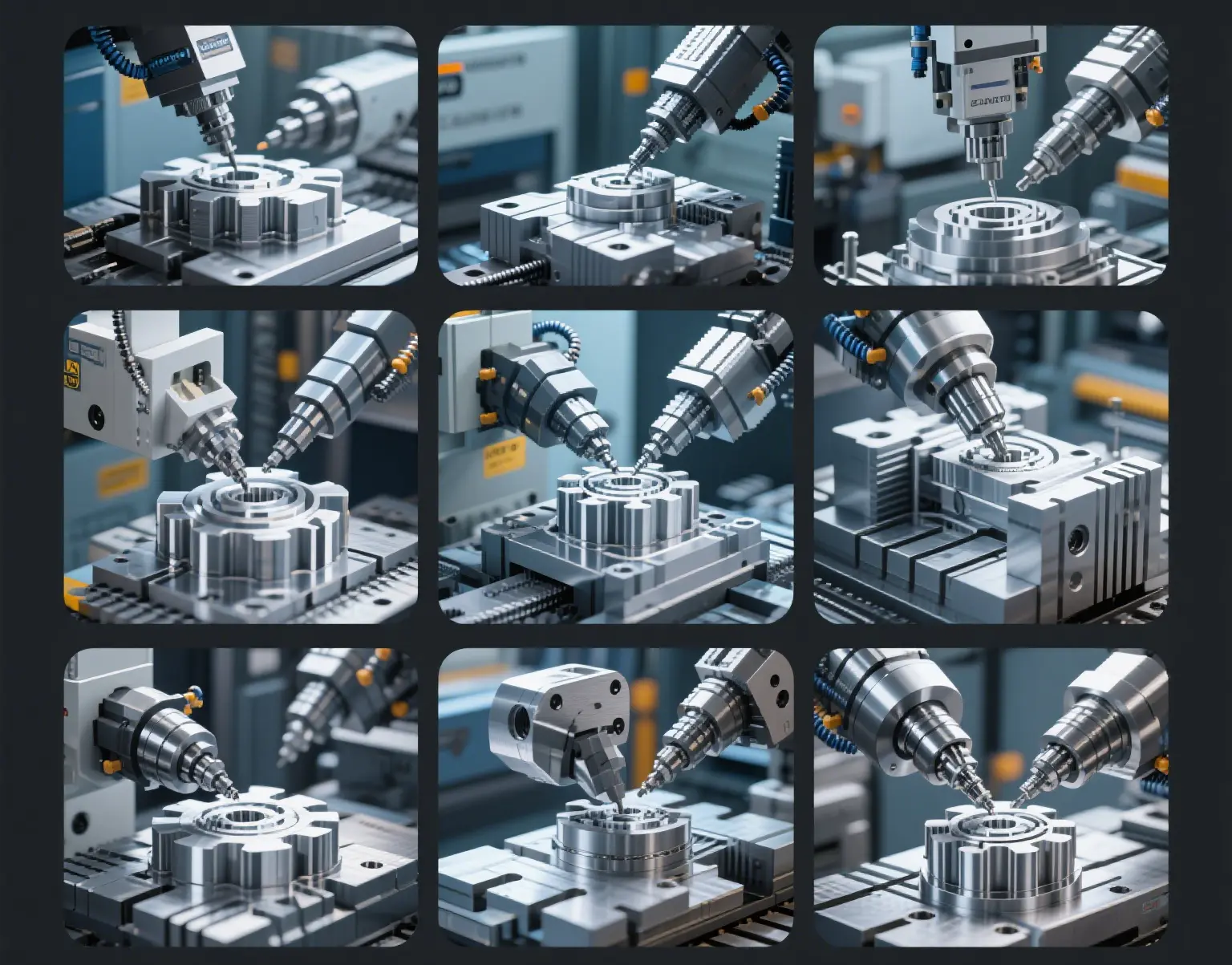

- CNC Machining: Precision components like lens mounts, sensor housings, and intricate metal parts are best produced with high-precision 5-axis CNC machining.

- Laser Cutting: For flat, detailed components, laser cutting using acrylic or polycarbonate materials allows for rapid optical testing and evaluation.

- Testing & Validation:

Once a prototype is produced, it must be rigorously tested. Environmental tests (vibration, thermal cycling) and optical alignment verification via interferometry ensure that the prototype can perform under real-world conditions. Early-stage testing helps identify design flaws and refine the product before large-scale production.

Cost to Prototype a LiDAR Product

Cost depends on the prototyping method and component complexity. Here’s a sample cost breakdown:

| Component | Prototyping Method | Cost Range |

|---|---|---|

| Laser Housing | CNC Machining | $500 – $2,000 |

| Optical Lens | Precision Grinding | $1,000 – $5,000 |

| PCB Assembly | Rapid Prototyping | $300 – $1,500 |

This table provides a rough idea of the cost ranges for essential components. Early prototyping costs may be higher due to short-run inefficiencies but tend to decrease as volumes increase or when hybrid sourcing is employed.

Challenges in LiDAR Prototyping

Key Considerations

- Optical Precision:

LiDAR systems demand sub-micron precision alignment, especially for laser diodes and lens assemblies. Any misalignment can drastically affect performance. - Thermal Management:

Prototypes typically need to withstand thermal cycling and proper heat dissipation. Compact designs require effective strategies to manage heat, such as enhanced cooling in CNC machining. - Regulatory Compliance:

Depending on the application—especially in automotive or industrial sectors—meeting standards like ISO 26262 is critical. This involves thorough testing and documentation.

Common Pitfalls

- Over-Engineering:

Overcomplicating the design early in the process can lead to unnecessary production costs. It’s vital to simplify designs where possible without compromising performance. - Material Mismatch:

Avoid using prototype-grade plastics for final product applications. Material substitution must be carefully evaluated to ensure durability and performance in the production phase.

Transitioning from Prototype to Production

Partnering with Prototype-to-Production Companies

Leading LiDAR hardware companies, such as Great Light CNC, provide end-to-end solutions to scale your product from prototype to mass production. Their comprehensive approach includes:

- Design for Manufacturability (DFM):

Optimizing initial designs to ensure that the product can be efficiently produced at scale while minimizing waste and reducing machining complexity. - Advanced Manufacturing Techniques:

- 5-Axis CNC Machining: Utilized for precision components such as sensor housings and mounting brackets, ensuring tight tolerances (±0.005 mm).

- Injection Molding: Best suited for high-volume production of polymer components once the design is finalized.

- Supply Chain Integration:

Seamless sourcing of optics, sensors, and semiconductor components is vital. Reliable partners can ensure consistent material quality and timely delivery.

Case Study: Autonomous Vehicle LiDAR Sensor

- Client: An emerging autonomous vehicle startup.

- Challenge: Transitioning from 10 prototypes to an annual production of 5,000 units while maintaining high precision and reducing costs.

- Solution:

- Leveraged Great Light’s 5-axis CNC machining to produce aluminum sensor housings with tolerances of ±0.01 mm.

- Implemented in-house anodizing for enhanced corrosion resistance.

- Result: Achieved a 40% cost reduction compared to traditional methods and scaled production efficiently.

Top Prototype-to-Production LiDAR Companies

Selecting the right partner can significantly influence your project’s success. Here’s a brief comparison:

| Company | Specialization | Key Strengths |

|---|---|---|

| Great Light CNC | Precision machining & assembly | 5-axis CNC expertise, ISO 9001-certified, end-to-end services |

| Velodyne Lidar | Full-stack LiDAR solutions | Proprietary sensor technology, market leadership |

| Luminar | Long-range automotive LiDAR | Scalable production pipelines, robust R&D |

| Hesai Technology | MEMS-based LiDAR systems | High-volume manufacturing, rapid prototyping |

These companies illustrate a range of strengths from high-precision manufacturing to scalable production, helping you choose a partner that best fits your technical and budgetary needs.

Cost-Saving Strategies for LiDAR Production

To optimize cost efficiency when transitioning from prototype to production, consider the following strategies:

- Modular Design:

Reuse common components across multiple product lines to reduce development and production costs. - Bulk Material Purchasing:

Negotiate favorable rates for raw materials like aluminum or titanium when scaling production volumes. - Hybrid Prototyping:

Combine rapid prototyping methods like 3D printing (for non-critical parts) with high-precision CNC machining for essential components. - Efficient Supply Chain Integration:

Work with partners offering integrated solutions (e.g., material sourcing, machining, and post-processing) for smoother production workflows and cost control.

How to Choose a Prototype-to-Production Partner

5 Essential Criteria

- Technical Expertise:

The partner must have proven experience in LiDAR-specific manufacturing, including optical alignment and precision machining. - Scalability:

Their ability to scale production from 10 prototypes to 10,000+ units without compromising quality is critical. - Certifications:

Verify that the company holds industry certifications, such as ISO 9001, IATF 16949 (automotive), or ISO 13485 (medical), which attest to their quality processes. - Post-Processing Capabilities:

In-house services for anodizing, laser marking, and sealing are vital for ensuring the final product meets performance and durability standards. - Location and Logistics:

Regional production can reduce logistics costs; for instance, a partner like Great Light offers global production with strong support in Asia and complementary local offices.

Red Flags to Avoid

- Limited Material Options:

A supplier unable to source high-quality, aerospace-grade materials can hinder product performance. - No Testing Support:

Companies without in-house environmental or optical testing capabilities may fail to guarantee product reliability. - Vague Pricing Models:

Look out for hidden fees, unclear setup costs, or lack of transparency regarding tooling expenses.

Future Trends in LiDAR Manufacturing

The LiDAR industry continues to evolve with new technologies and process optimizations:

- Automation and AI:

AI-driven quality control and toolpath optimization are emerging, ensuring more accurate, efficient, and predictable manufacturing. - Miniaturization:

There is a trend towards ultra-compact LiDAR systems for drones and wearable technologies, pushing the limits of precise machining. - Sustainability:

Recyclable materials and energy-efficient production processes are becoming more prevalent, aligning with global environmental standards. - Hybrid Manufacturing:

Integrating additive (3D printing) with subtractive (CNC machining) processes allows for the production of complex near-net shape components with minimal waste.

Why Partner with Great Light CNC?

As a leader in prototype-to-production CNC machining, Great Light CNC is at the forefront of LiDAR hardware manufacturing. Our strengths include:

- 5-Axis Precision:

Our state-of-the-art machines deliver ultra-precise components with tolerances as tight as ±0.005 mm, perfect for intricate LiDAR housings and structural elements. - End-to-End Solutions:

We offer a complete suite from initial design consultation (DFM analysis) and prototyping to final assembly, ensuring your product transitions seamlessly from concept to mass production. - Cost Efficiency:

Great Light provides competitive pricing that is 30–50% lower than many North American suppliers, thanks to our global production capabilities. - Global Logistics and Quality Assurance:

With ISO 9001 and other industry certifications, our processes are rigorously monitored for precision and reliability. Our global logistics network ensures fast, on-time delivery.

Conclusion – Transforming Your LiDAR Hardware Journey

Transitioning from prototype to production for LiDAR hardware is a challenging yet rewarding process that requires precision engineering, innovative manufacturing technologies, and experienced partners. By understanding the prototyping process, key cost drivers, and strategic partnering considerations outlined in this guide, you can effectively navigate the journey from concept to market-ready product.

For startups and established enterprises alike, working with a trusted partner like Great Light CNC ensures that your LiDAR hardware is produced with uncompromising quality, efficiency, and cost-effectiveness. Our commitment to innovation and excellence means that you can focus on driving your business forward while we handle the manufacturing complexities.

Start Your LiDAR Journey Today:

- Upload your CAD files for a free DFM analysis.

- Receive instant, transparent quotes tailored to your project needs.

- Enjoy end-to-end support from prototyping to mass production.

Request a Quote – Innovate Faster, Scale Smarter!