1. Scope

1. This standard specifies tolerance levels and limit deviation values of general tolerances for linear and angular dimensions for which tolerances are not specified.

2. This standard applies to the dimensions of metal cutting processing, and also applies to the dimensions of general stamping processing of non-metallic materials and other processing methods.

3. Processing dimensions can be adopted as a reference.

4. This standard only applies to the following dimensions without tolerances

5. Linear dimensions such as external dimensions, internal dimensions, step dimensions, diameter, radius, distance, chamfering radius and chamfering height.

6. Angle dimensions include angle dimensions that do not usually indicate angle values, such as those mentioned in right angles or except for the angles of equipolygons.

7. Linear and angular dimensions of machined assemblies

This standard does not apply to the following sizes

1. Linear and angular dimensions involved in other general tolerance standards

2. Reference dimensions in parentheses

3. The correct theoretical size in the rectangular frame

2. Reference standards

The provisions contained in the following standards constitute the text of this standard by reference in this standard. The versions indicated at the time of publication of the standards are.

To remain valid, all standards are subject to revision. Parties using this standard should explore the possibility of using the latest edition of the following standards:

1. GB/T 1800.1-1997 Limits and bases of coordination, part 1, vocabulary

2. GB/T 1184-1996 Shape and position tolerances do not indicate tolerance values

3. GB/T 4249-1996 Tolerance principles

4. GB/T 6403.4-1986 Rounding and chamfering of parts

3. Definition

1. This standard adopts the relevant terms and definitions given.

2. General tolerances

These are dimensions with general tolerances that can be guaranteed under normal workshop processing conditions. It is not necessary to indicate the limit deviation value after the dimensions.

Note: The Guidance Appendix appendix gives the concept and explanation of general tolerances.

4. General principles

The tolerance levels specified in this standard take into account the general manufacturing accuracy of various factories. If higher tolerance requirements are required for a certain item due to functional requirements, they must be marked directly on the drawing in accordance with the provisions of GB/T. 1182; more daring. Tolerance requirements should only be met if it is economically advantageous for the plant.

Where geometric tolerances specified in this standard are used in drawings or related documents without tolerances being noted, they shall be marked in accordance with the provisions of Chapter 6 of this standard, which applies to all elements which do not are not individually marked with geometric tolerances.

In addition to tolerances not stated for each element specified in this standard, other elements such as line, surface contour, inclination, position and total runout shall be determined by the injected geometric tolerance or not indicated, the linear dimensional tolerance or the angular tolerance of each element. control.

5. Tolerance levels and limit values for deviations from general tolerances

General tolerance levels are divided into precision, medium roughness and coarser. The total tolerance level is divided into linear dimensions and angular dimensions without tolerances.

The deviation limit values for each tolerance level are not indicated.

5.1 Linear dimensions

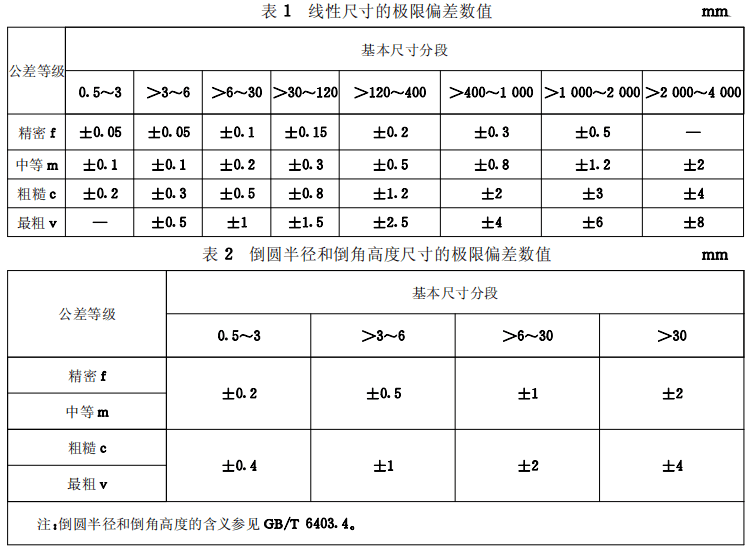

Table 1 gives the limit deviation values for linear dimensions

Table 2 gives the limit values for deviations from the dimensions of the rounding radius and the chamfering height.

5.2 Angular dimensions

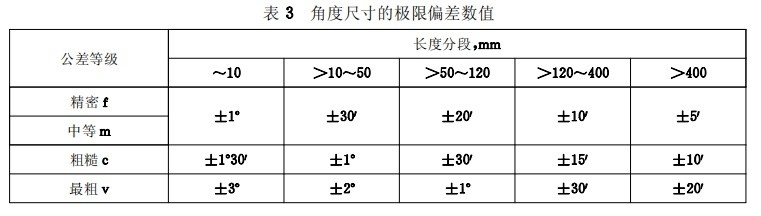

Table 3 gives the limit values for deviation of angular dimensions. The value is determined based on the length of the short side of the angle. For the angle of the cone, it is determined according to the length of the first line of the cone.

6. Drawing representation without tolerance values

If the general tolerance specified in this standard is adopted, the standard number and tolerance quality code should be noted near the title bar of the drawing or in technical requirements and technical documents such as corporate standards. For example, when selecting medium quality. must be marked as follows:

GT/T 1804-m

7. Judgment

Unless otherwise stated, when the geometric error of a part element exceeds the unstated tolerance value but the function of the part is not damaged, the part should generally not be rejected.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.