Why Small Scale Production Before Product Prototype Phase is Essential for Success

When companies venture into new product development, every stage plays a crucial role, particularly small scale production before full prototyping. This phase has become pivotal for ensuring not only the functionality and feasibility of product designs but also for minimizing risk and enhancing market responsiveness. Small scale production acts as a preliminary test, allowing companies to verify concepts, adjust processes, gather user feedback, and optimize for market readiness.

In this article, we’ll explore in-depth the benefits of small-scale production, covering feasibility testing, market risk reduction, process optimization, and acceleration of product launch. We’ll also discuss how precision CNC machining and rapid prototyping can further enhance these stages.

Understanding Small Scale Production Before Full Prototyping

Before committing to large-scale manufacturing, companies can benefit immensely from small-scale production, which enables them to produce limited quantities to refine design, analyze feasibility, gather user insights, and establish quality control. This step helps avoid potential setbacks in full scale production by validating the design’s viability and making necessary adjustments early in the development process.

1. Verifying Feasibility and Functionality of Product Design

Functional Testing

Small scale production is a valuable opportunity for initial functional testing. By creating a limited batch of the product, companies can conduct hands-on evaluations to ensure that the design specifications translate well into physical form. This stage identifies potential design flaws and addresses them before entering the prototype or large scale production phase, thereby reducing costly mistakes.

User Experience Evaluation

Another advantage of small scale production is the ability to conduct user experience trials. Bringing the product to a select audience of target users provides direct feedback on usability, functionality, and appeal. Collecting user insights at this stage allows for informed iterations and modifications, ensuring the product aligns with market needs and user expectations.

2. Reducing Market Risks

Market Demand Validation

Small scale production provides an excellent way to gauge market demand. By releasing a limited quantity to select markets or audiences, companies can test whether there’s genuine demand for the product. Data collected from this initial market exposure allows the company to adjust product features, marketing strategies, and production volume based on real-world feedback, reducing the risk of launching a product that may not perform well in the market.

Cost Control

Small scale production helps manage and anticipate costs before committing to a larger rollout. Manufacturing a smaller batch allows companies to calculate initial production costs more accurately, which provides valuable insights for setting prices and developing cost-efficient production processes. This approach minimizes the risk of under- or overpricing, improving both profitability and competitiveness.

3. Optimizing Production Processes

Process Improvement

The small scale production phase allows for fine-tuning manufacturing processes. By running the product through a preliminary production cycle, companies can identify areas where the process can be streamlined, improving efficiency and reducing waste. Process improvements made during this phase are beneficial in ensuring a smoother transition to large-scale production.

Quality Control

Establishing quality control protocols is essential during small-scale production. Companies can use this stage to set benchmarks for quality and conduct rigorous testing to ensure each product meets performance standards. These measures ensure consistency and reliability, setting a foundation for higher quality in full-scale production.

4. Accelerating Product Launch

Shortening the R&D Cycle

Small scale production offers companies the chance to accelerate research and development. Through functional testing and user feedback, companies can quickly refine designs, enabling faster iterations and shorter development cycles. This efficiency not only speeds up the product launch timeline but also improves the product’s relevance and appeal by meeting evolving market demands.

Flexible Strategy Adjustments

With insights from market testing and user feedback, companies can make informed, flexible adjustments to product strategies and production plans. This agility allows them to react swiftly to changing market conditions or consumer preferences, ensuring the product remains relevant and competitive.

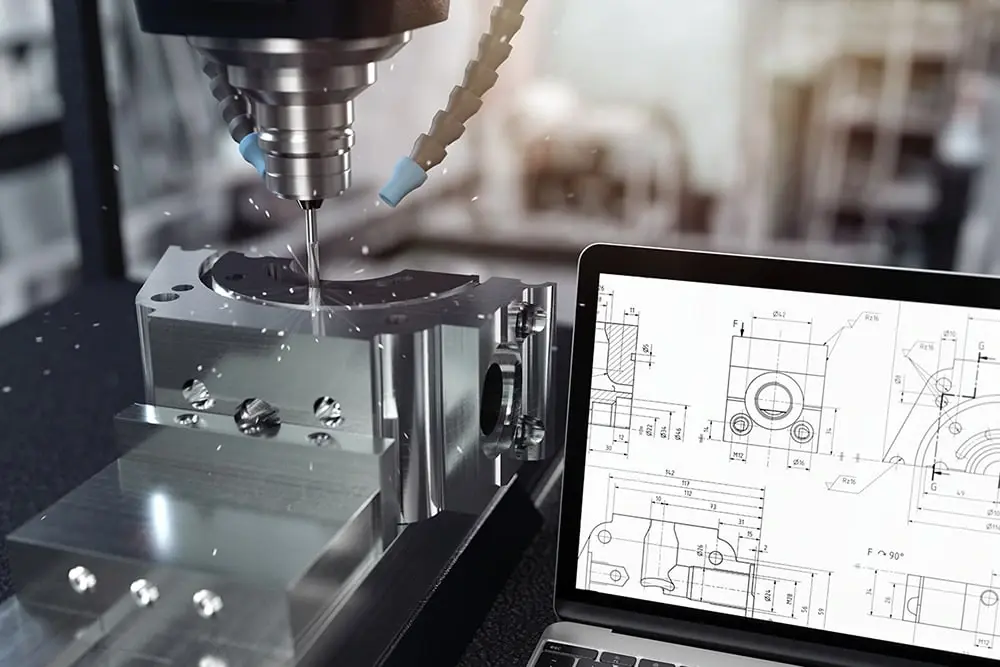

Leveraging Precision CNC Machining and Rapid Prototyping in Small-Scale Production

GreatLight, a trusted name in CNC machining and rapid prototyping, offers advanced solutions tailored to meet the demands of small-scale production. Equipped with state-of-the-art 5-axis and 4-axis CNC technology, GreatLight ensures precise, high-tolerance manufacturing, enabling companies to create functional prototypes and small production runs efficiently. This precision is essential for quality control, allowing companies to identify and resolve potential production challenges early.

Benefits of CNC Machining for Small-Scale Production

- Accuracy and Repeatability: CNC machining delivers high precision, ensuring consistent quality across all units, which is crucial for testing product viability.

- Efficient Material Use: By optimizing material use, CNC machining reduces costs, which is vital when experimenting with small-scale production.

- Quick Turnaround: GreatLight’s rapid prototyping capabilities mean faster iteration, which helps companies respond quickly to testing outcomes and market feedback.

Conclusion

Small Scale Production Before Product Prototype Phase is a strategic approach that provides invaluable insights into product feasibility, cost, and market demand. By verifying design functionality, gathering user feedback, minimizing risks, optimizing processes, and accelerating the R&D cycle, companies can position themselves more effectively for a successful product launch. Utilizing precise CNC machining, such as that offered by GreatLight, can further enhance the benefits of small-scale production, ensuring high-quality outcomes, cost-efficiency, and timely delivery.

For companies aiming to bring innovative, high-quality products to market, embracing small scale production as an integral part of the development process is key to unlocking competitive advantage and long-term success.

By integrating the insights from small scale production into the product development lifecycle, companies can significantly increase their chances of market success, reduce risks, and ensure their products meet both company standards and market demands.