In the manufacturing sector, the integration of new technologies is the key to remaining competitive in an increasingly demanding and dynamic global market. The adoption of new tools is often aimed at increasing efficiency, reducing time and costs, and improving the parts manufactured. For example, additive manufacturing is being integrated as a transformative technology in industries that use well-established traditional processes. Whether as a complementary tool or in a hybrid system,3D printing is fully compatible with traditional methods.

Traditional manufacturing remains the method of mass production, but it faces challenges in sustainability, design flexibility and material efficiency. Yet its ability to produce large quantities at low cost remains unmatched in many cases. The need to innovate and adapt to modern requirements is driving the adoption of process improvement technologies such as additive manufacturing. Understanding the importance of having the best of both worlds, here we explore how additive manufacturing complements other production methods. 8 reasons.

1: Rapid prototyping

Rapid prototyping offers several advantages over traditional manufacturing methods. It allows you to imagine several iterations to validate the design before mass producing the final part. Additive manufacturing is an ideal tool for designing prototypes. Thanks to their flexibility, these products can be manufactured at lower cost, without using existing tooling, and relatively quickly. Many businesses rely on 3D printing to validate their concept before choosing another more suitable manufacturing method. Additionally, rapid prototyping helps reduce waste associated with trial and error in traditional manufacturing. By leveraging the design flexibility offered by additive manufacturing, resource usage can be optimized and waste minimized. This is not the case for subtractive technologies like machining. This approach, combined with the ability to manufacture on demand, also eliminates the need for large inventories and minimizes waste associated with overproduction.

2: More efficient mold

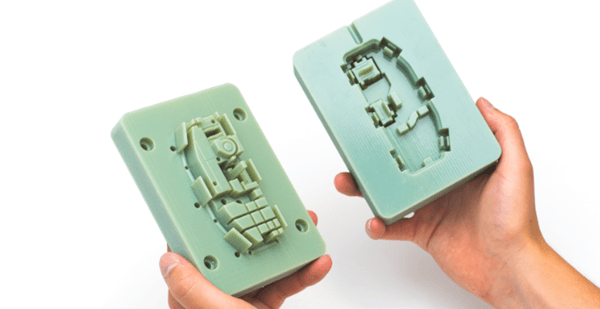

3D printing allows you to create molds for processes such as injection molding. Since molds can be printed with complex geometries, such as cooling channels, it is possible to achieve better heat distribution and faster cooling times for parts. In contrast, functional mold designs can be created easily and quickly, whereas traditional mold manufacturing can take weeks or even months, depending on the complexity of the mold.

3D printing accelerates and optimizes injection mold production (Photo: Protolabs Network)

3: 3D printed model for lost wax casting

Lost wax casting is a traditional process for manufacturing high precision parts. 3D printing can create models with complex, detailed designs in wax or burnout resin that would be difficult to create using traditional methods. Ultimately, this not only reduces production time but also eliminates the need for expensive tools such as molds. Additionally, with 3D technology, model designs can be iterated quickly, making adjustments easier before entering the prototyping phase. This approach therefore combines the flexibility of digital design with the precision of traditional manufacturing.

4: Optimization of cutting tools

In addition to improving the final part, additive manufacturing can also help optimize the traditional mold itself. Milling tools (usually made from carbide inserts) wear quickly due to the heat generated during the cutting process. They are also difficult to manufacture by machining. to use With 3D printing, tools can be created with custom geometries and internal cooling channels to dissipate heat in the cutting zone, significantly extending tool life and performance.

5: Manufacturing fixtures and fittings

In manufacturing, jigs and fixtures are essential tools designed to improve process accuracy, efficiency and repeatability. With additive manufacturing, jigs and fixtures can be produced more quickly and customized to meet the specific needs of each process. These include, for example, drilling jigs, fixtures, welding jigs and molds, etc. As a result, a welding jig can be printed that ensures precise positioning of parts in complex assemblies, minimizing human error and maximizing repeatability. This is particularly useful in industries such as automotive and aerospace, where precision is essential to product functionality and safety.

Jigs and fixtures guarantee the precision of traditional manufacturing (Photo credit:Pieces to take away)

6: Combined materials

Another reason to integrate additive manufacturing into traditional processes is that multiple materials can be used in a single part during the manufacturing process. 3D printing makes it easier to use advanced materials such as alloys, ceramics or reinforced polymers to create complex internal structures or custom components that would be difficult to achieve using traditional methods.

With hybrid manufacturing, materials can be combined during the manufacturing process, such as when a product requires heat or tensile strength in one area rather than the entire part. By following this procedure, manufacturers can use specific materials for the parts they need and use more economical materials for the rest of the part without altering the final quality.

7: Repair and maintenance

3D printing also contributes to the maintenance, repair and aftermarket of traditional manufacturing by providing fast and efficient solutions to extend the life of tools and components. For example, with reverse engineering, a physical part can be analyzed via 3D scanning, creating a digital copy that can be converted into a CAD model. The model can then be modified or replicated to restore obsolete or hard-to-find parts, avoiding long delivery times and higher costs associated with replacement.

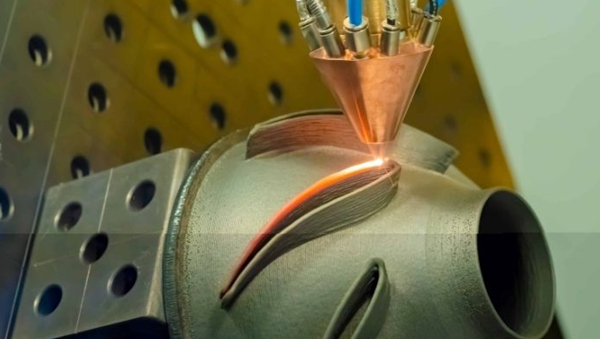

Additionally, the concentrated energy depositionThe 3D printing process (DED) makes it possible to repair metal parts by adding material only to the damaged area, while preserving the rest of the structure. This is particularly useful in applications where parts are expensive or lead times are long. Not only does this reduce costs over time, but it also minimizes waste by preventing the premature disposal of repairable tools or equipment.

DED technology can apply metal or aluminum alloys to the parts you need.

8: Faster time to market

By leveraging additive manufacturing’s ability to quickly create prototypes, products can be brought to market faster. 3D printed prototypes allow companies to validate and test their designs faster and more cost-effectively than traditional methods, significantly reducing product development time. Using this technology, companies can cost-effectively produce small batches of products while waiting for large-scale production facilities to be ready to operate.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.