In 2004, Professor Behrokh Khoshnevis of the University of South Carolina pioneered 3D printing technology for concrete walls. A truly iconic innovation in the construction industry is its Contour Crafting technology, which allows a house to be built in a fully automated manner in just 20 hours. The professor developed an FDM-type 3D printer mounted on a robotic arm capable of extruding concrete instead of plastic to create layers from a 3D model. Behrokh Khoshnevis was quick to demonstrate the benefits of additive manufacturing in the construction sector: reduced costs and waste, increased production speed, fewer workplace accidents and the ability to create complex shapes. His research marked the beginning of architectural 3D printing and paved the way for 3D printing of houses.

Construction industry leaders are beginning to take full noticeThe enormous potential of 3D technology and its impact on the future of the field. According to a recent market study conducted by Precedence Research, the 3D printing in construction market is expected to reach $1,418.16 billion by 2034, with an annual growth rate of 65%. This expansion is not the result of chance: more and more companies are adopting this technology to develop projects. Some of these projects are futuristic, while others have already come to fruition, such as the world’s largest 3D printed building in Saudi Arabia, measuring 9.9 meters high. 3D printing in construction is developing rapidly, integrating various technologies and materials, and has many advantages. But what does this technology really mean? What are the benefits for the industry? What are the future prospects? To find out more, continue reading this article.

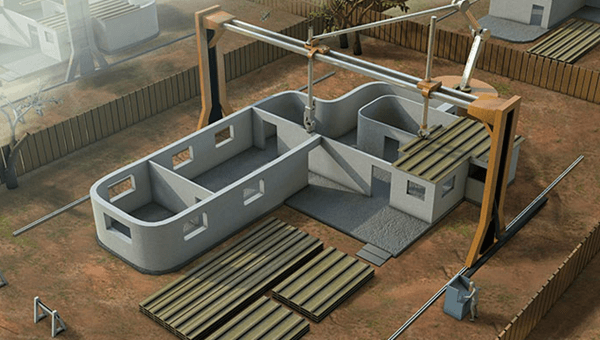

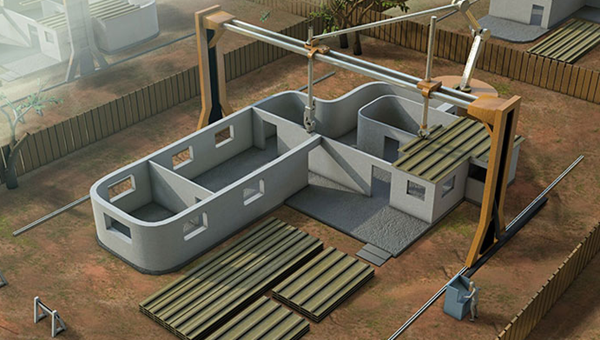

Figure 1: Early development of the contouring process.

What are the current construction sectors?3D printing process?

Robotic arm extrusion material

The Contour Crafting method marks the debut of 3D printing in the construction sector. This process involves laying down building materials to form a 3D model, enabling the creation of large-scale structures with a smooth surface finish. Guide rails are installed around the building floor to guide the robotic arm. The arm moves back and forth to apply the concrete layer by layer. Fixed paddles placed on both sides and above the nozzle flatten the extruded layer, ensuring adequate strength. Traditional concrete cannot be used for this process because it cannot support its own weight. We therefore use a specific concrete which hardens more quickly and allows for faster configurations.

Figure 2:Use a robotic arm3D printing.

The technologies used and developed by the different players in the field are very similar and based on the same basic principle: material extrusion. For example, FrenchConstructions-3D has designed a mobile polar machine capable of printing directly on construction sites, in the center of buildings under construction. The machine, easy to transport and highly adaptable, consists of a mechanical base and a robotic arm equipped with an extruder nozzle developed by the company. The arm has a printing area of 150 square meters and a printing height of up to 7 meters.

Some companies choose to focus on extruding materials other than concrete while maintaining the same technical principles. An example is a patentBatiPrint 3D process developed in cooperation with the University of Nantes, Bouygues Construction and Lafarge Holcim. The industrial robot places three layers of material directly on site: two layers of expanded polymer foam and a layer of concrete. “The foam provides thermal and acoustic insulation, while the concrete reinforces the structure, making it anti-seismic,” explains Benoit Furet, professor at the University of Nantes.

Figure 3: Development of BatiPrint additive manufacturing technology

junction of sand layers

In Europe, the ItaliansEnrico Dini developed a process using his D-Shape 3D printer. The system is based on the use of powder, which is solidified by a binder in the form of “ink”. In this process, a layer of sand or aggregate is deposited to the required thickness, then a print head equipped with 300 nozzles deposits droplets of adhesive which harden the sand. The machine has a cubic shape measuring 4 x 4 meters and is capable of creating large structures up to 6 cubic meters.

metals for solid structures

Dutch companyMX3D has developed an innovative construction method, WAAM (Arc Additive Manufacturing), which allows the use of 6-axis robots to manufacture metal structures. The robot can deposit up to 2 kilograms of material per hour, making the technology particularly suitable for complex and detailed welding work on metal structures in buildings.

To develop their technology,MX3D collaborates with Air Liquide and ArcelorMittal. The robot is equipped with a welding machine and nozzles that weld metal rods layer by layer. The process is compatible with a variety of metal alloys, such as stainless steel, bronze, aluminum or Inconel. In short, it is a “giant welding machine”: “We combined an industrial robot with a welding machine, to make a 3D printer that works with our own software,” explains the team.

Figure 4: MX3D robotic arm

Why used in construction3D printing?

One of the main advantages of 3D printing concrete is that it saves a lot of time. In fact, 3D printing can reduce construction time by 70% while reducing risks and accidents on site. Benoit Furet explains: “Reducing difficulties and risks is a reality and we built the 3.8 m high wall without scaffolding. In addition, we noticed that the construction site was very quiet. » His team succeeded in 3D printing a 95 m² house, which will be the first 3D printed social housing in the city, according to him, BatiPrint technology also makes it possible to create curved shapes at lower cost and makes it possible to automate work: the 3D printer can work continuously until the end of the project, which significantly reduces waiting time.

Compared to traditional construction methods used in constructionAnother benefit of 3D printing is the reduction in material usage. Unlike subtractive processes, the gradual addition of material limits the environmental impact and produces very little waste, largely thanks to topological optimization. Romain Duballet, co-founder of It becomes even more important.

Figure 5:by a French companyStructure created by XtreeE

One of the main challenges facing 3D printing in the construction sector is the lack of clear standards for certifying printed structures. Axel Thery, business manager at Constructions-3D, explains: “The main difficulty comes from the fact that 3D printing is not yet recognized as a construction method that complies with the codes and standards in force. Since printed structures are non-traditional, this is difficult. to assess their long-term robustness. This is why buildings intended for habitation must be tested step by step from the start”

However, some countries are starting to consider developing standards to integrate this technology into the construction sector. For example, in Dubai, the United Arab Emirates authorities are consideringUse 3D technology to build 25% of new buildings in 2030.

On the one hand, additive manufacturing creates many jobs, but what about construction workers? housesWill 3D printing and automation of construction processes make many jobs obsolete? What skills are needed to operate a 3D printer on a construction site? Concrete 3D printing experts agree that technology will transform these professions, but it will not eliminate them. We are seeing changes in career profiles. Benoit Furet explains: “Professions will continue to evolve, from architects to masons to masonry operators. Ultimately, the entire digitalization process will become simpler and construction professionals will take on the role of digital masons and robot controllers. »

Figure 6: Will 3D printed houses change current jobs?

The solution to the housing crisis?

3D printing allows structures to be created more quickly, which could provide an ideal solution to the housing crisis by providing affordable housing that can be built more quickly. Some companies have already adopted this technology for this purpose, such as the Italian WASP, which aspires to build a more sustainable world through 3D printing. The company has developed one of the world’s largest 3D printers, capable of building homes using local materials and renewable energy sources such as solar, wind or hydroelectric power. This allows even areas without electricity to create eco-friendly structures using local resources.

Figure 7:Italian companyDevelopment of WASP.

Some countries are considering3D printing as a solution to the housing crisis. For example, in Chile, the Casa Semilla project, the result of a collaboration between the University of Biobio and ANID, was recently launched. The move comes as more than half a million people in the country suffer from a housing shortage. Built in just 29 hours, the house is earthquake resistant, durable and adaptable to different regions of Chile, providing an innovative and feasible solution to housing problems.

While additive manufacturing could provide a solution to Earth’s housing crisis, it could also play a key role in space exploration, including building homes in space. The idea is already thereIt was explored as part of NASA’s 3D Printed Habitat Challenge, which aims to design technology to build habitats on the Moon or Mars. However, there are still many obstacles to overcome before we can see printed structures in space.

Figure 8:Moon3D printing projects

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.