CNC parameters are the soul of CNC machine tools. Normal operation of CNC machine tool software and hardware is “communicated” via parameters. Manufacturing accuracy and accuracy recovery after maintenance of machine tools also need to be adjusted via parameters. There are no parameters, CNC machine tools are equivalent to a pile of scrap metal. If all CNC parameters are lost, the CNC machine tool will be paralyzed.

There are many parameters related to servo control in the CNC system. CNC systems from different CNC manufacturers have different parameter names, types and functions. Whether the parameter settings are correct or not will directly affect the accuracy and stability of the feed movement. Users without experience and authority are prohibited from adjusting these parameters at will, otherwise the CNC machine tool may not work properly.

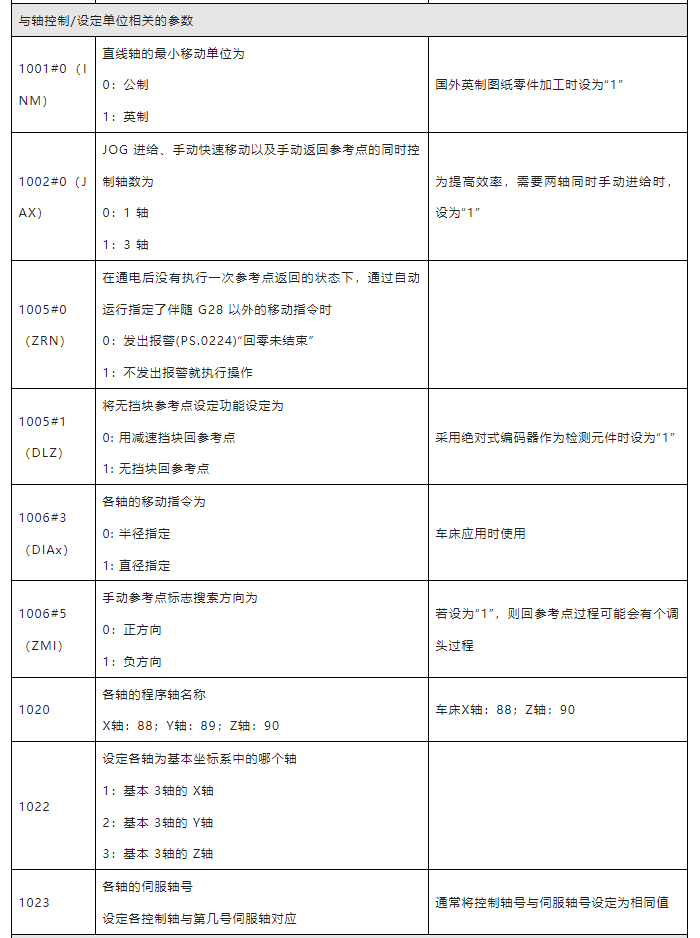

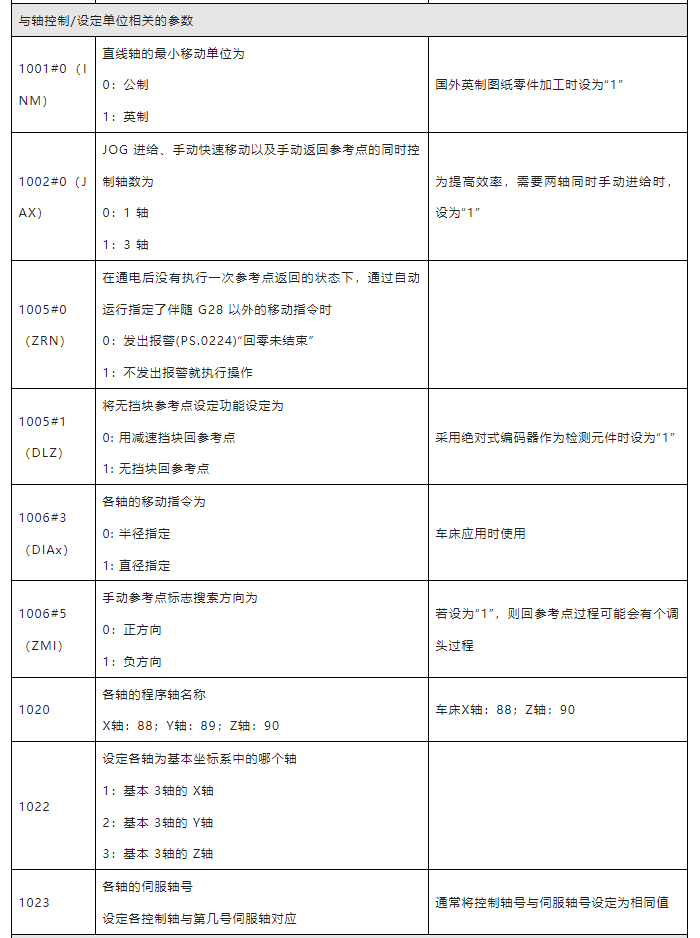

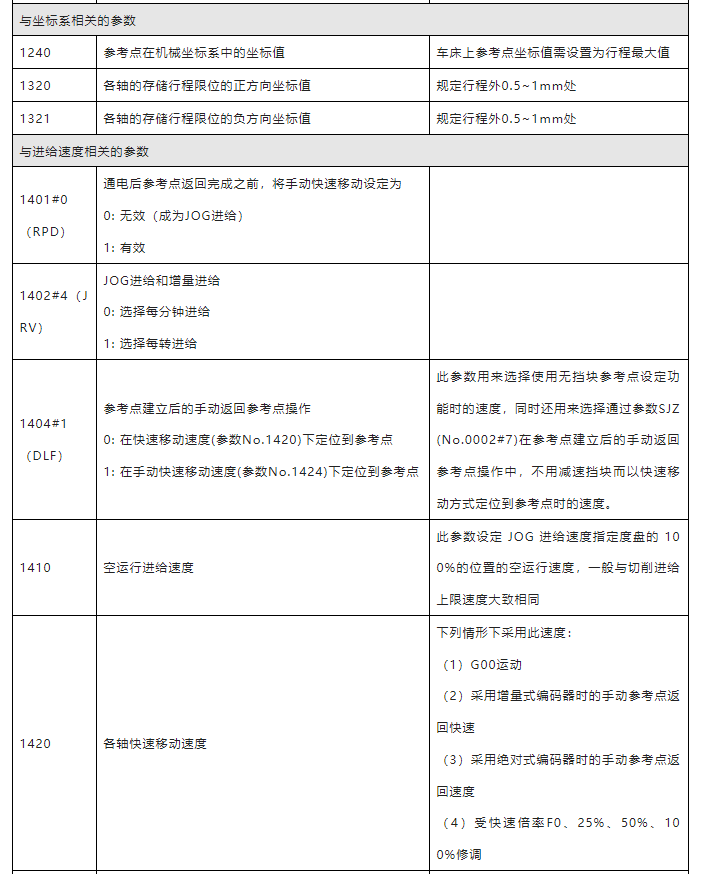

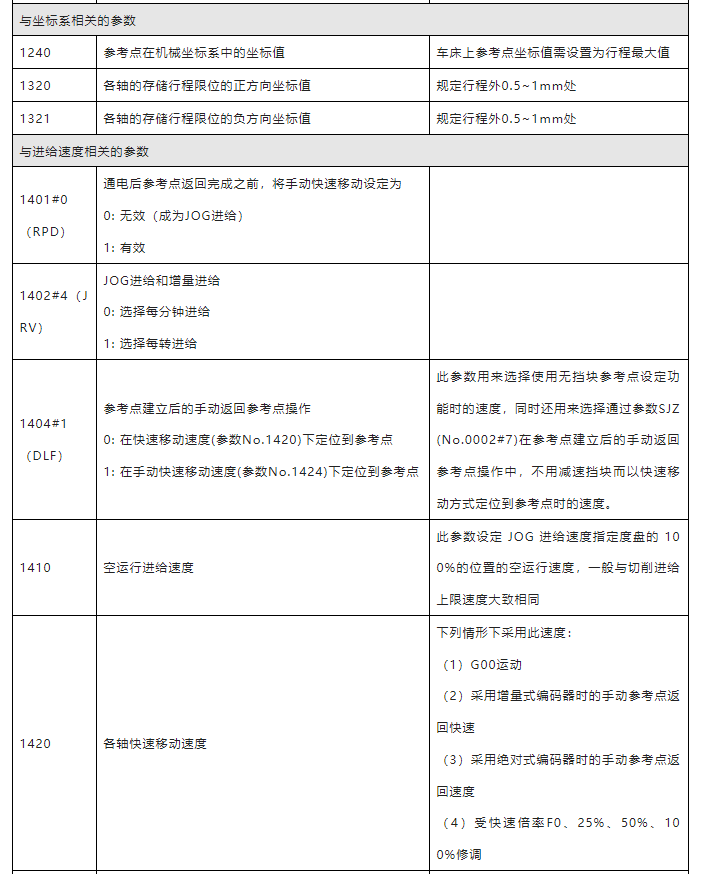

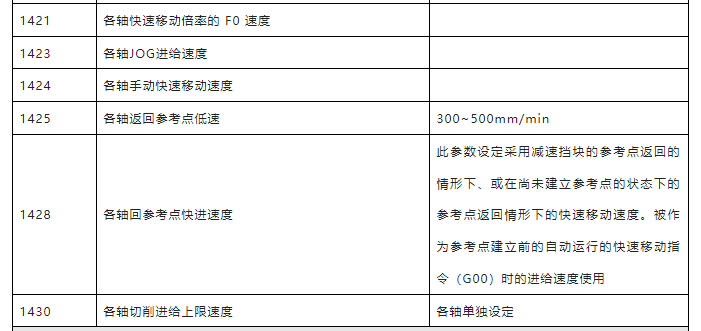

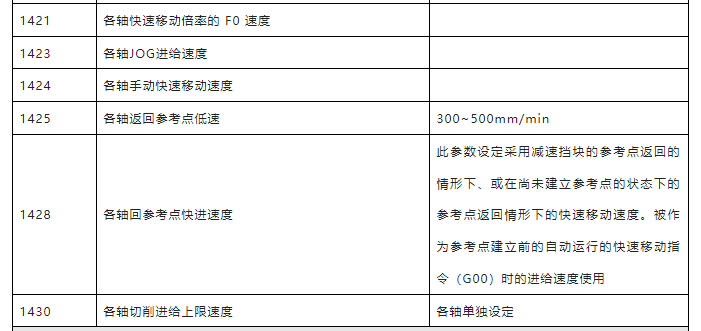

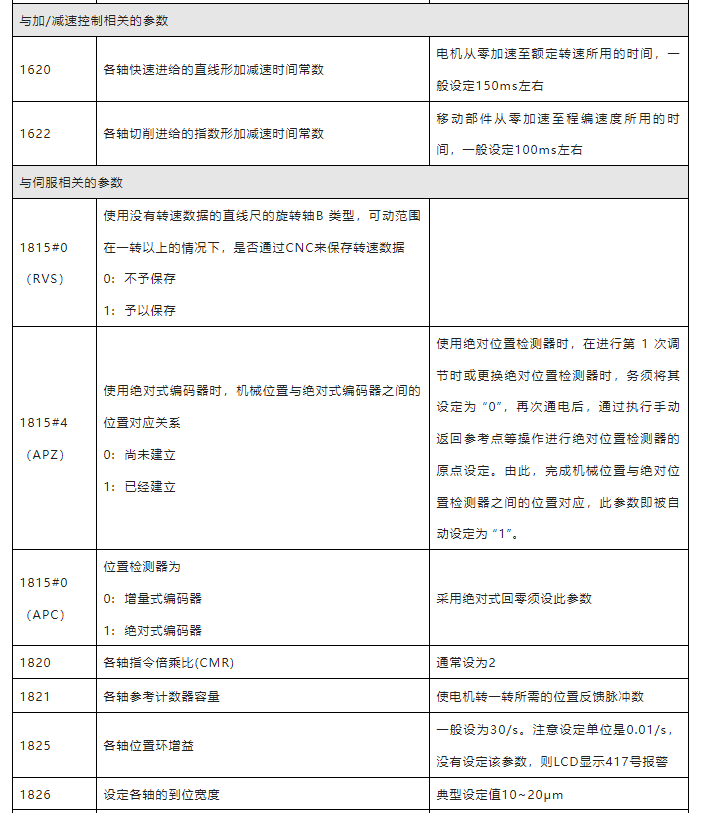

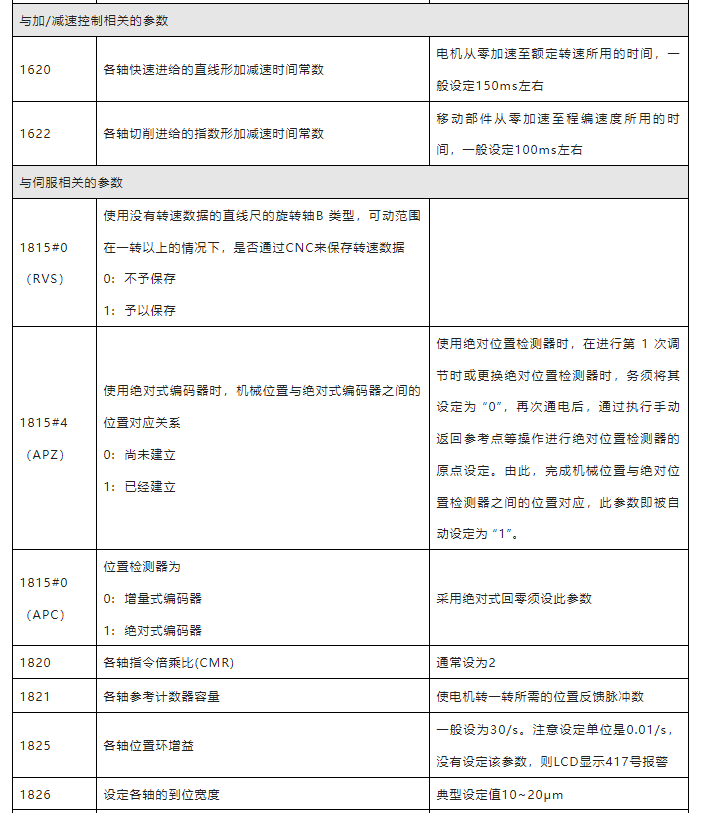

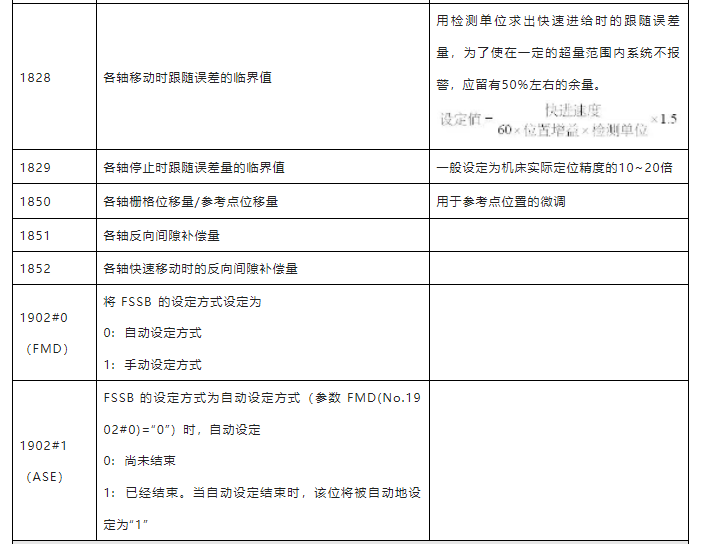

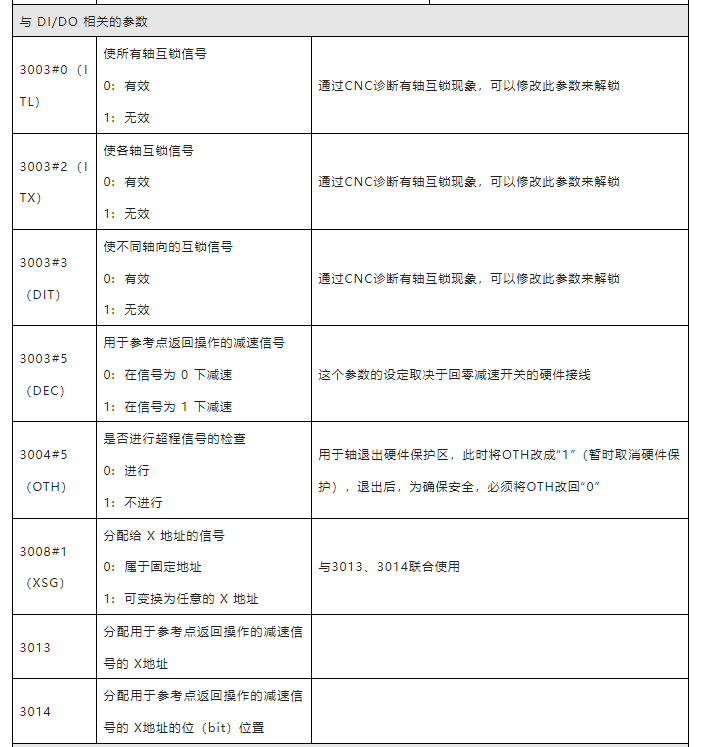

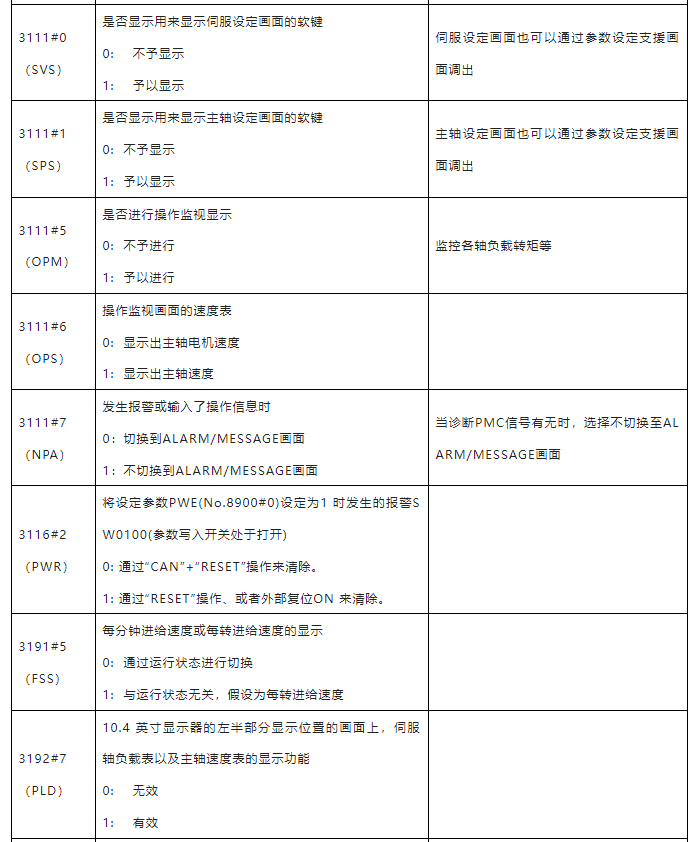

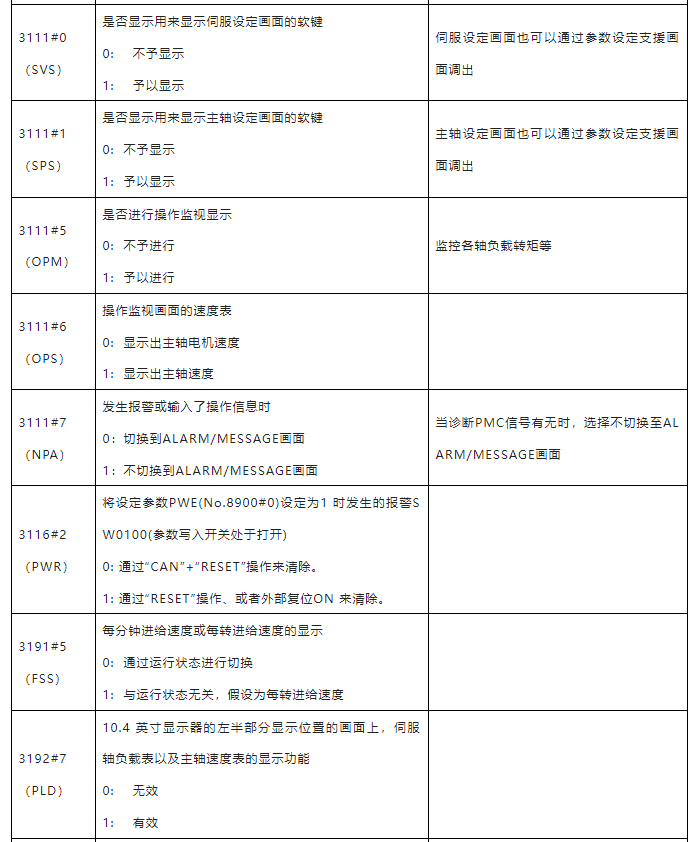

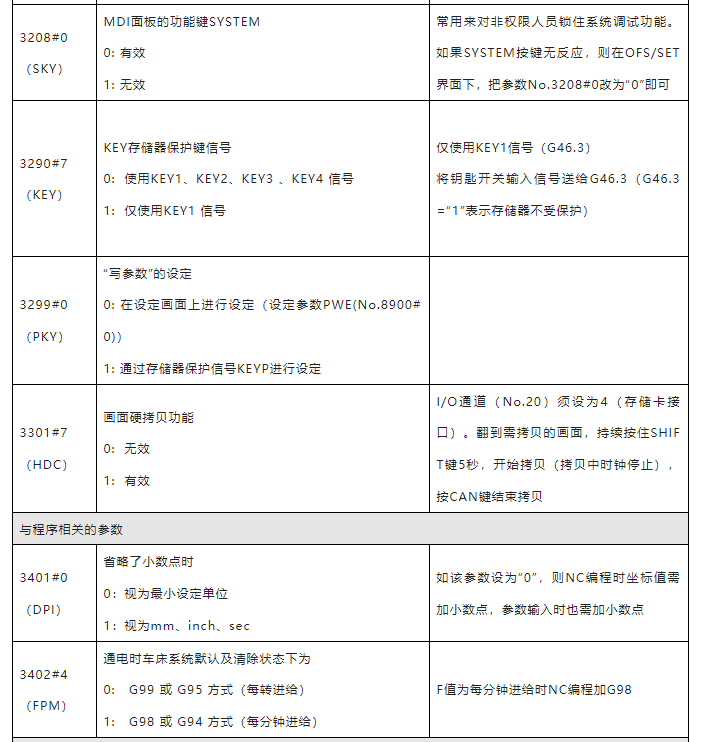

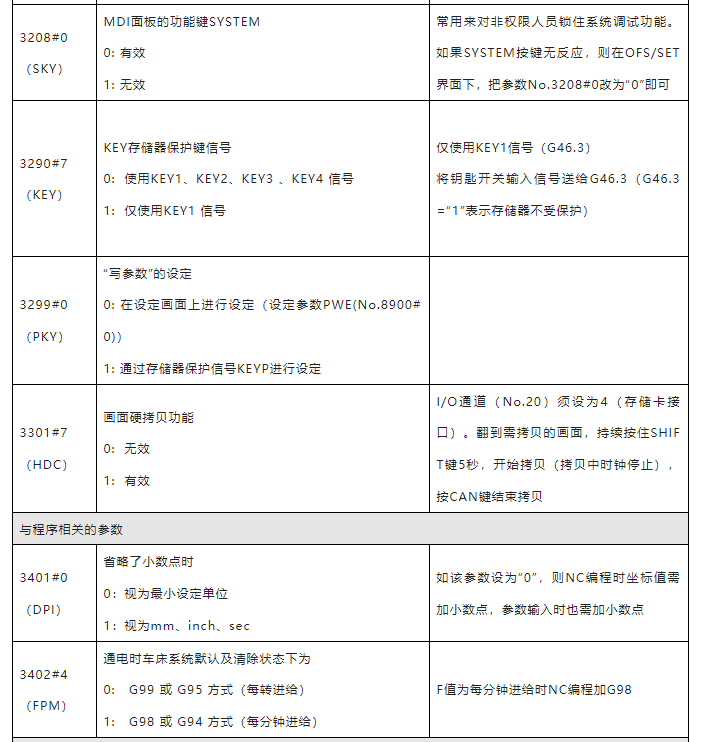

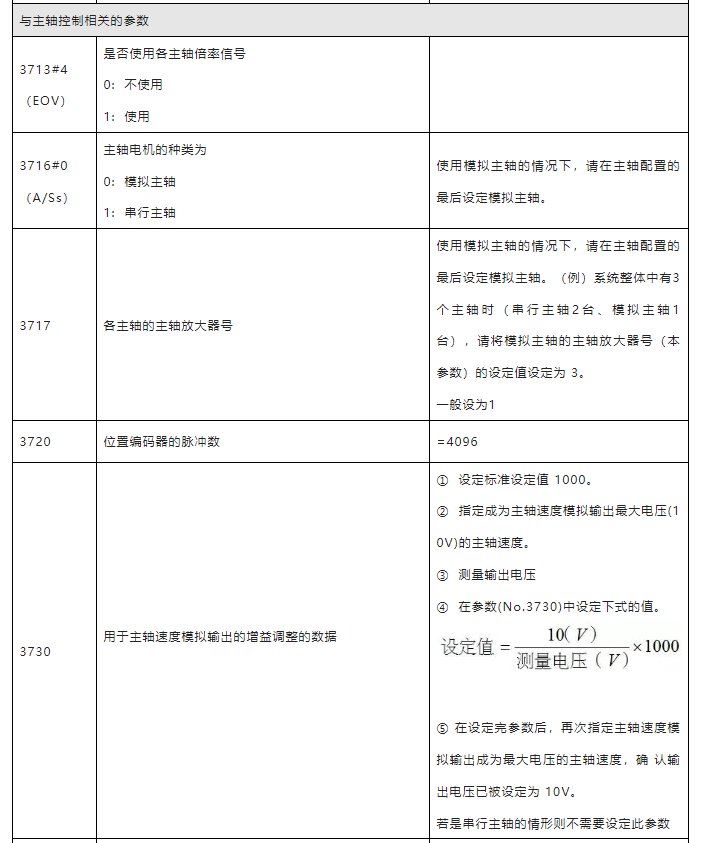

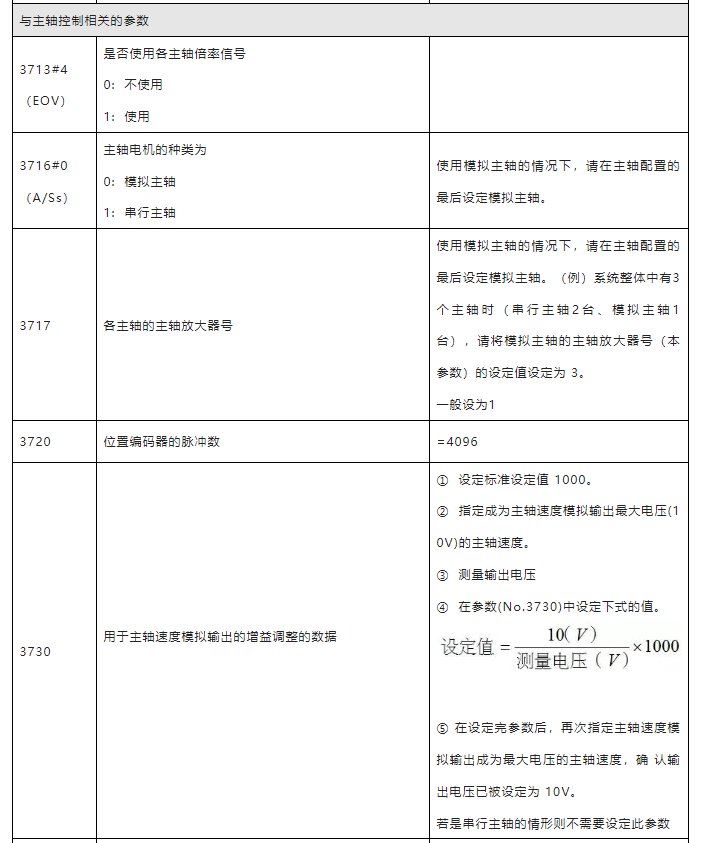

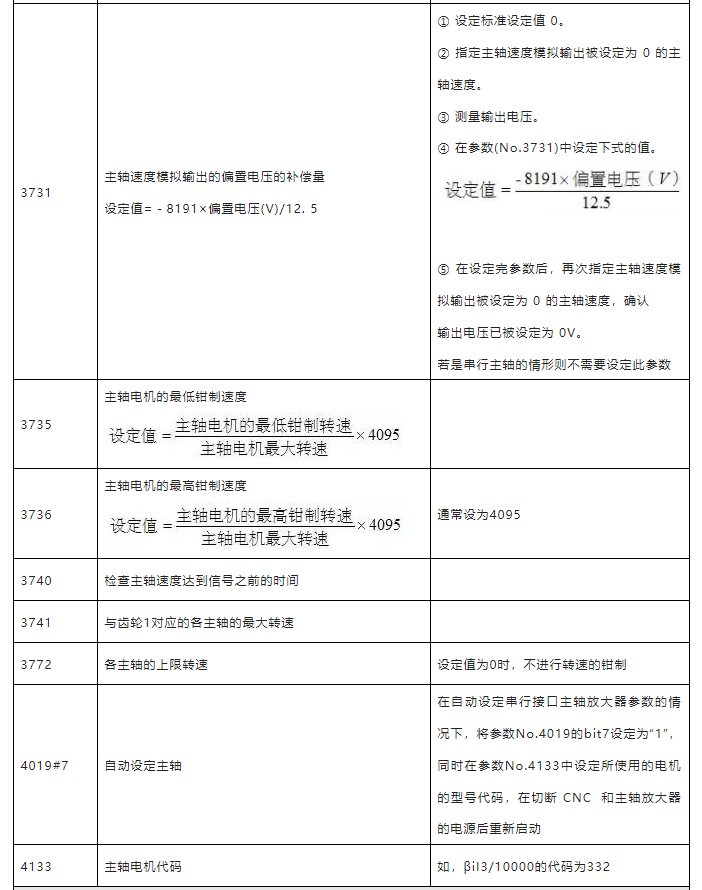

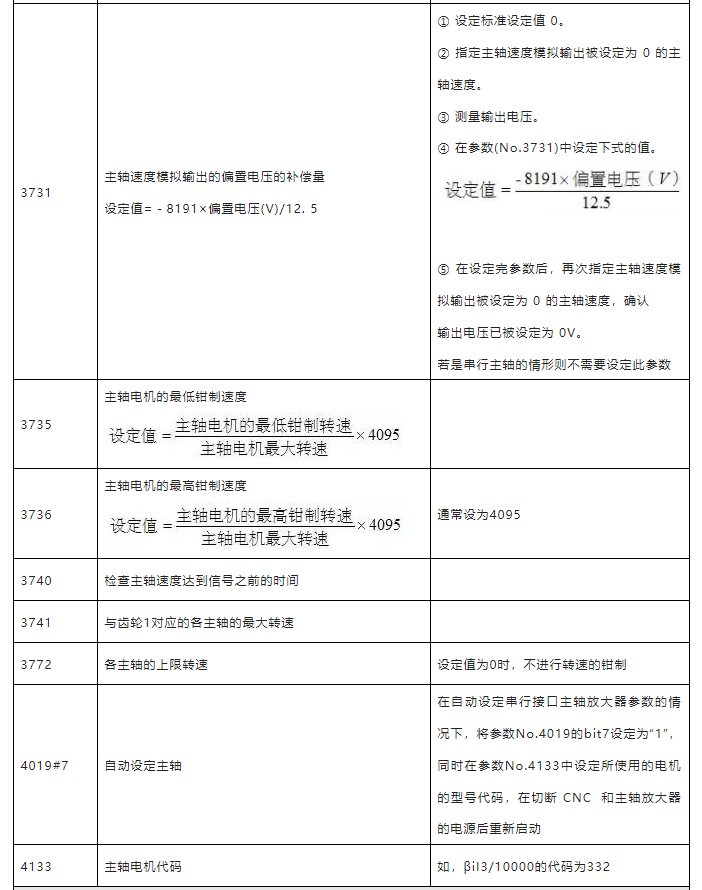

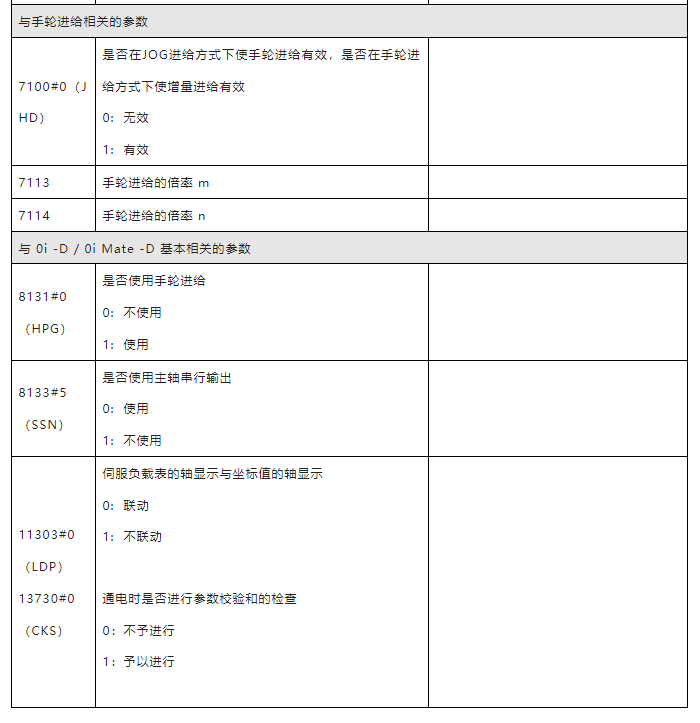

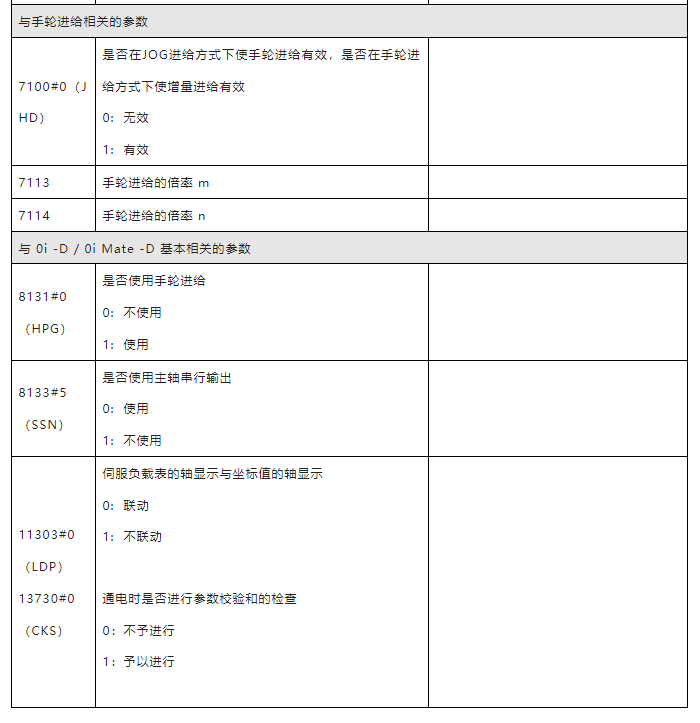

The following lists the most commonly used CNC parameters in FANUC system applications, hoping to help you quickly find the parameters you need.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.