As a machining veteran, you’ve read countless pictures and dealt with countless things. When we talk about “geometric tolerance”, we are talking about professional knowledge that is both theoretical and practical. How well do you know her? In production, if we misunderstand the geometric tolerances shown on the drawings, the processing analysis and processing results will deviate from the requirements and even cause serious consequences. Today, let’s systematically understand the 14 geometric tolerances.

Let me show you the key points first. The following table presents the internationally unified 14-element geometric tolerance symbols. This is very important.

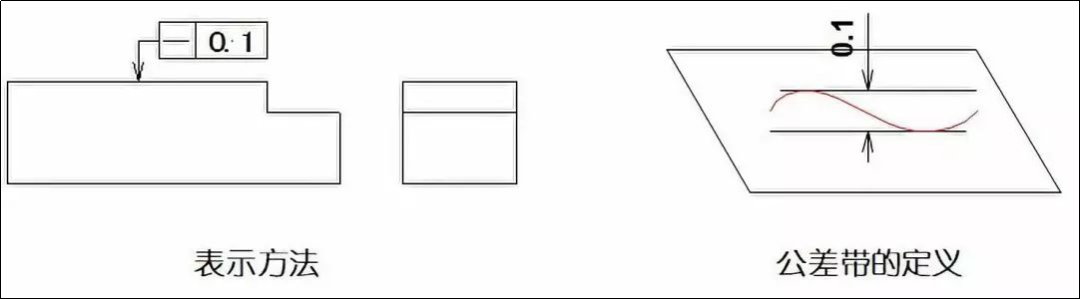

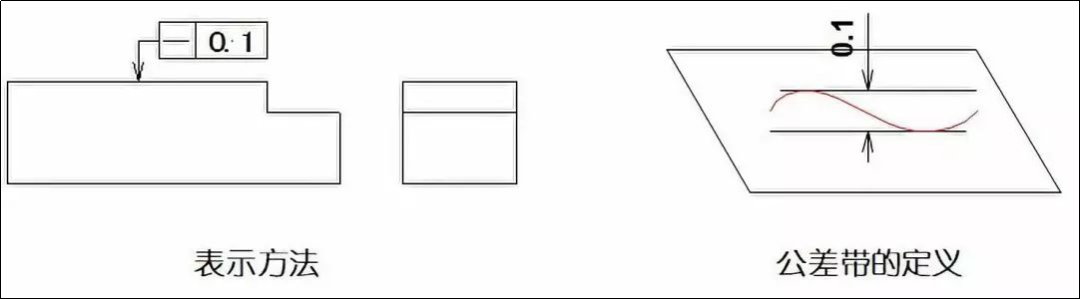

01 Straightness

Straightness, commonly referred to as straightness, refers to whether the actual shape of the straight line elements on the workpiece maintains an ideal straight line. Straightness tolerance is the maximum allowable variation of an actual line from an ideal straight line.

Example 1: In a given plane, the tolerance zone must be in the area between two parallel lines spaced 0.1 mm apart.

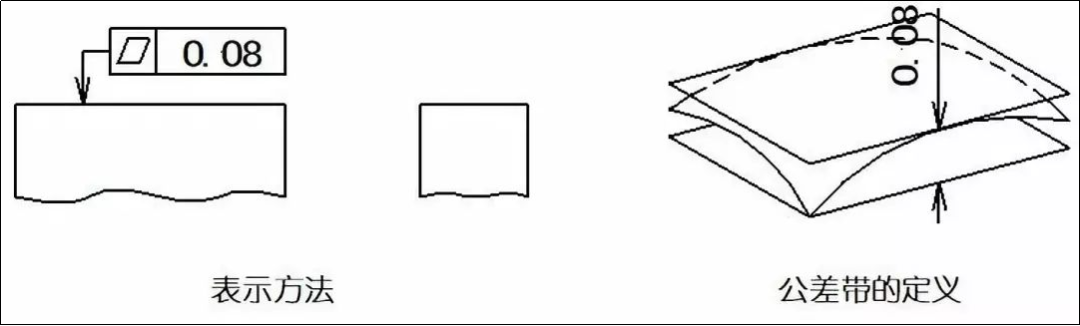

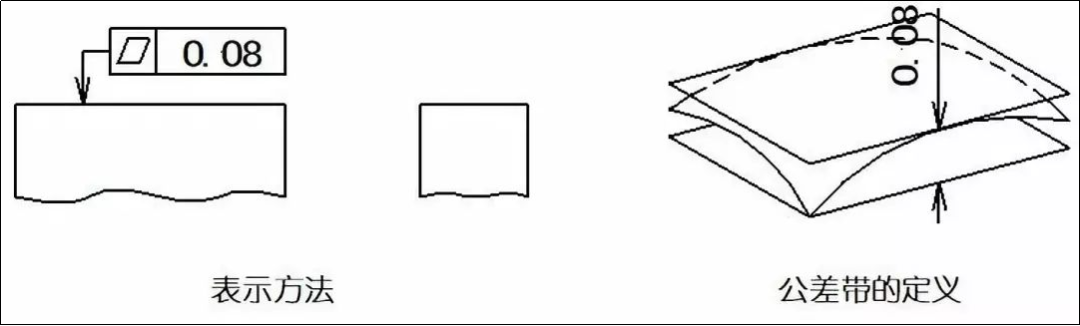

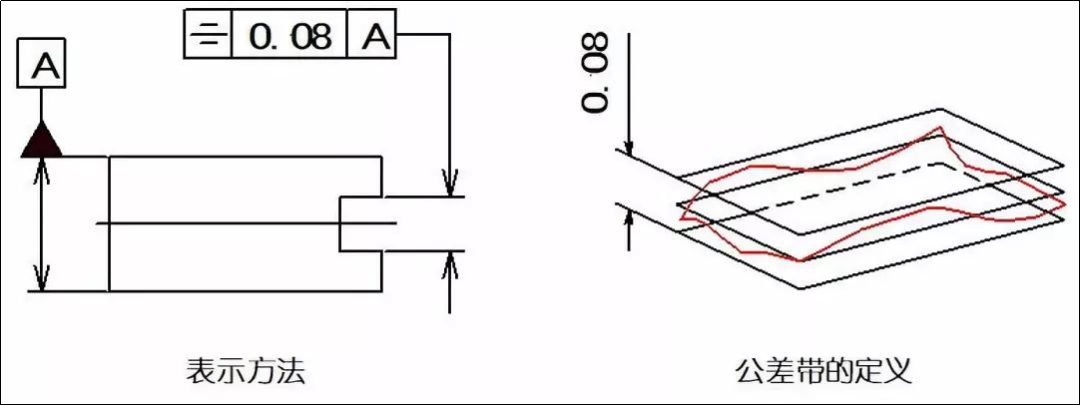

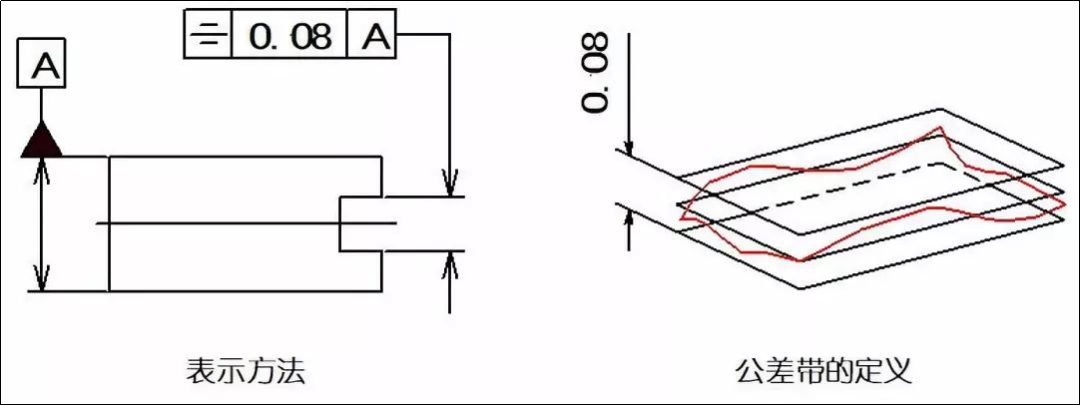

02 Flatness

Flatness, commonly called flatness, indicates the actual shape of the planar elements of the part and the condition of maintaining an ideal plane. Flatness tolerance is the maximum allowable variation of an actual surface from an ideal plane.

Example: The tolerance zone is the area located between two parallel planes 0.08 mm apart.

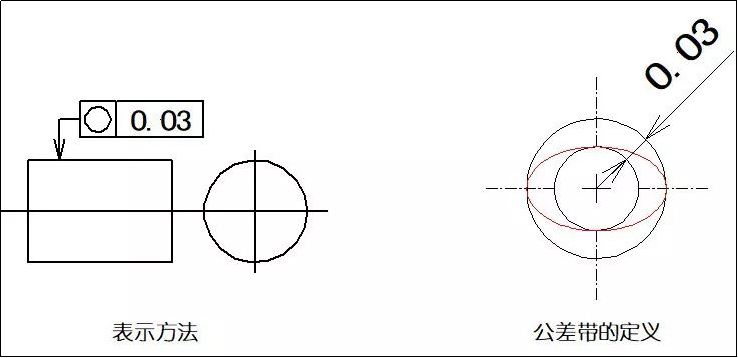

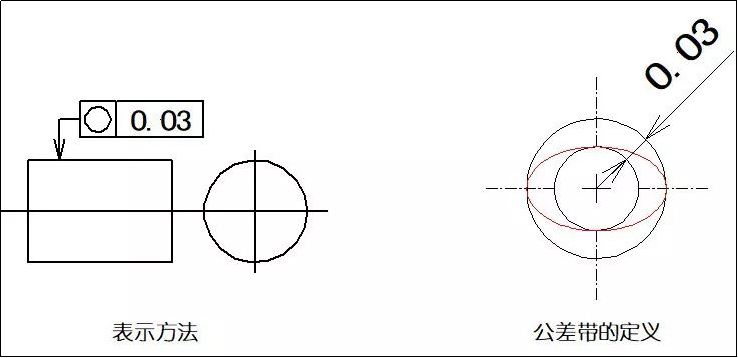

03 roundness

Roundness, commonly referred to as roundness, refers to the fact that the actual shape of a circular element on a part is equidistant from its center. The roundness tolerance is the maximum allowable variation of the actual circle compared to the ideal circle on the same section.

Example: The tolerance area should be on the same normal section, and the radius difference is the area between two concentric circles with a tolerance value of 0.03 mm.

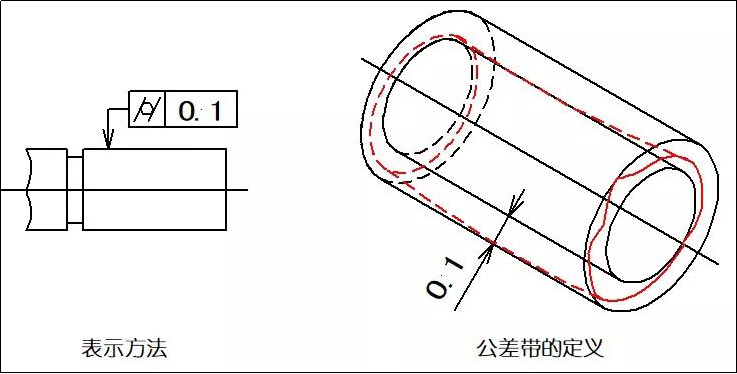

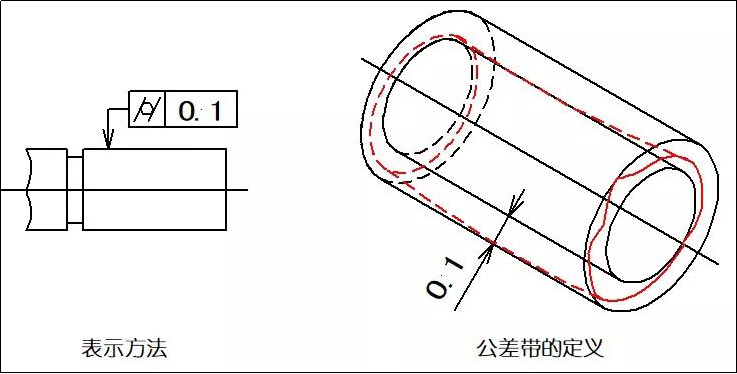

04 Cylindricity

Cylindricity means that all points on the contour of the cylindrical surface of the part are equidistant from its axis. Cylindricity tolerance is the maximum variation allowed between an actual cylindrical surface and an ideal cylindrical surface.

Example: The tolerance zone is the area between two coaxial cylindrical surfaces with a radius difference of a tolerance value of 0.1 mm.

Profile 05 lines

Line profile refers to the condition that any curve, regardless of its shape, maintains its ideal shape on a given plane of the part. Line profile tolerance refers to the allowable variation in the actual contour of a non-circular curve.

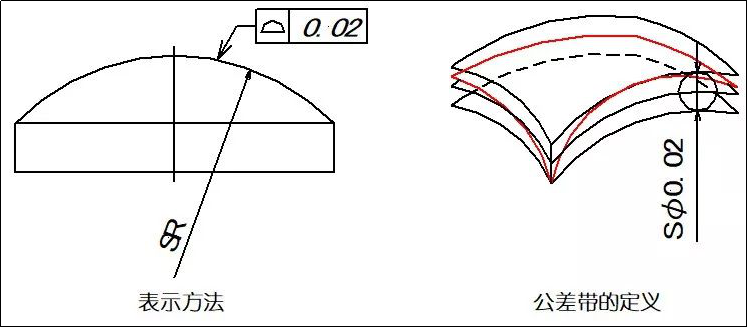

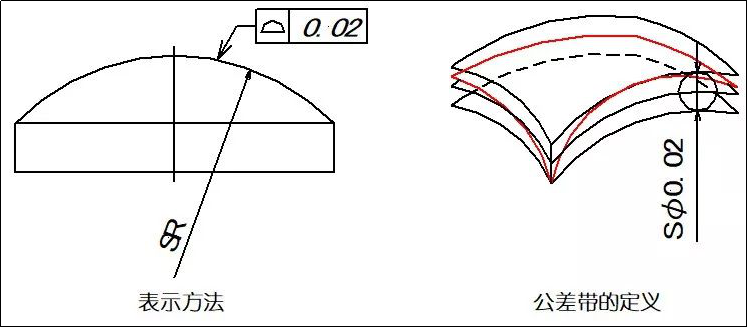

06 Surface contour

Surface contour refers to the condition in which an arbitrarily shaped surface on a part maintains its ideal shape. Surface contour tolerance refers to the actual contour line of a non-circular surface and the allowable variation from the ideal contour surface.

Example: The tolerance zone is located between two envelope lines enveloping a series of balls with a diameter of 0.02 mm. The centers of the balls should theoretically be located on the surface of the theoretically correct geometric shape.

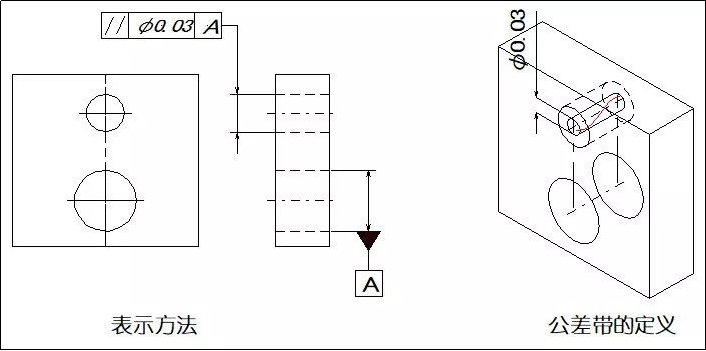

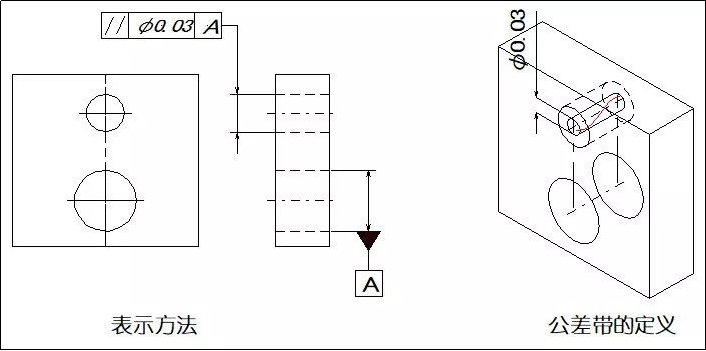

07 Parallelism

Parallelism, commonly called degree of parallelism, indicates that the actual elements measured on the part remain equidistant from the data. The parallelism tolerance is the maximum allowable variation between the actual direction of the measured element and the ideal direction parallel to the reference.

Example: If the Φ mark is added before the tolerance value, the tolerance zone is inside the cylindrical surface with a reference parallel diameter of Φ0.03 mm.

08 Verticality

The perpendicular, commonly called the degree of orthogonality between two elements, indicates that the element measured on the part maintains a correct angle of 90° with respect to the reference element. The verticality tolerance is the maximum amount of variation allowed between the actual direction of the measured element and the ideal direction perpendicular to the reference.

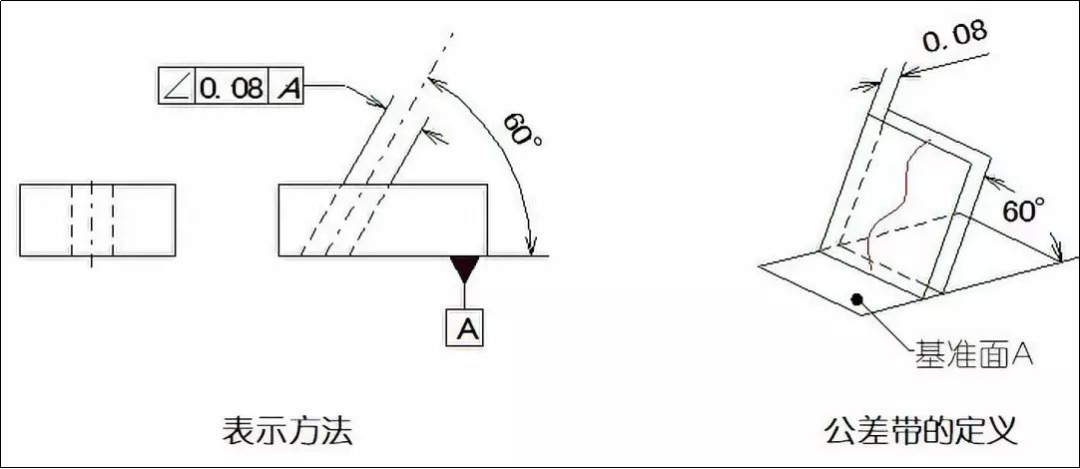

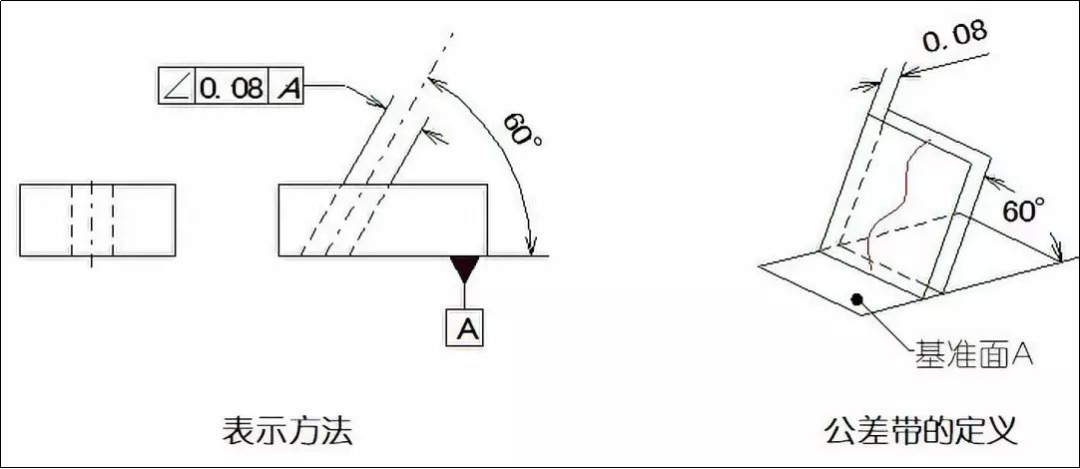

09 tilt

Tilt refers to the correct condition of maintaining a given angle between the relative directions of two elements of a part. The slope tolerance is the maximum amount of variation allowed between the actual orientation of the measured element and its ideal orientation at a given angle relative to the datum.

Example 1: The tolerance zone of the measured axis is the zone located between two parallel planes with a tolerance value of 0.08 mm and a theoretical angle of 60° with the reference plane A.

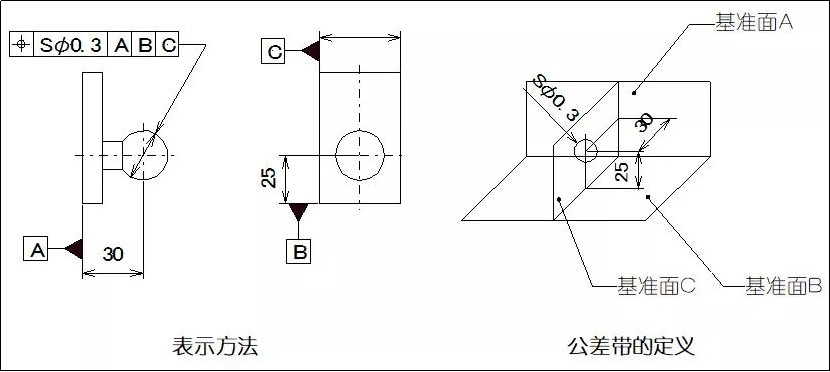

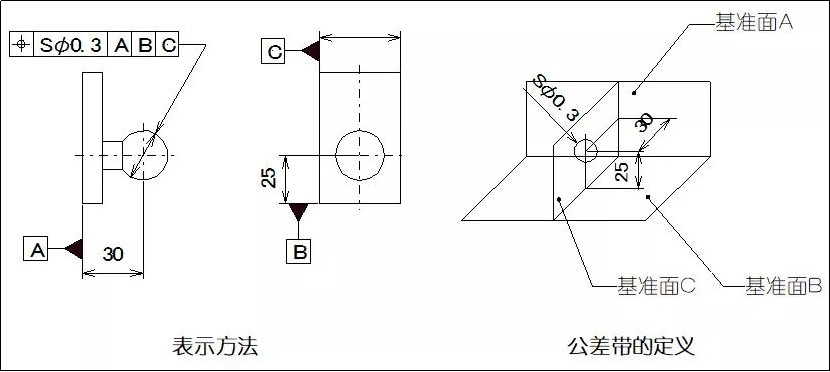

10 degrees of position

Position refers to the accuracy of points, lines, surfaces, and other elements in the part relative to their ideal positions. Position tolerance is the maximum allowable variation of the actual position of the measured element relative to its ideal position.

Example: When the SΦ mark is added before the tolerance zone, the tolerance zone is the area inside the ball with a diameter of 0.3 mm. The position of the center point of the ball tolerance zone corresponds to the theoretically correct size in relation to references A, B and C.

11 degrees of coaxiality (concentricity)

Coaxiality, commonly called coaxiality, indicates that the axis measured on the part remains on the same line in relation to the reference axis. The coaxiality tolerance is the allowable variation of the real axis measured relative to the reference axis.

12 degrees of symmetry

Symmetry refers to the state in which the two symmetrical center elements of the room remain in the same central plane. Symmetry tolerance is the amount of variation allowed by the central plane of symmetry (or centerline or axis) of the actual feature compared to the ideal plane of symmetry.

Example: The tolerance zone is the area located between two parallel planes or straight lines spaced 0.08 mm apart and arranged symmetrically in relation to the central reference plane or the central line.

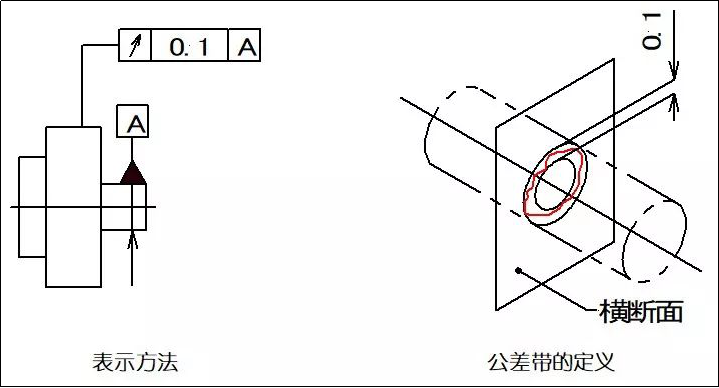

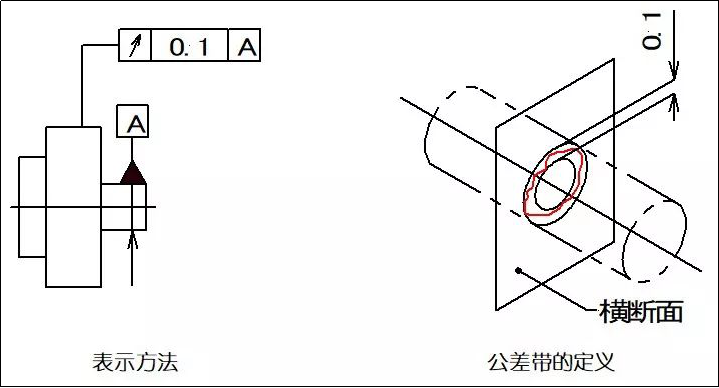

jump 13 circles

Circular runout means that the surface of revolution of the part maintains a fixed position relative to the reference axis in a limited measurement plane. Circular runout tolerance is the maximum variation allowed within a limited measuring range when the element actually measured rotates about the reference axis for one complete revolution without axial movement.

Example 1: The tolerance zone is the area located between two concentric circles perpendicular to any measurement plane, with a radius difference of 0.1 mm, and the center of the circle on the same reference axis.

14 complete beats

Total runout refers to the runout over the entire measured surface when the part rotates continuously around the reference axis. The total runout tolerance is the maximum amount of runout allowed when the actually measured item continues to rotate about the reference axis while the indicator moves relative to its ideal contour.

Example 1: The tolerance zone is the area between two cylindrical surfaces with a radius difference of 0.1 mm and coaxial with the reference.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.