1. Lead screw: linear transmission component. Its downstream applications are mainly in machine tools, industrial automation, automobile, etc. Humanoid robots should open up new spaces.

1.1 Screws mainly include trapezoidal screws, ball screws and planetary roller screws

The main function of threaded screw is to convert rotational motion into linear motion or convert torque into repeated axial force. It also has the characteristics of high precision, reversibility and high efficiency. The common forms of helical screw transmission mainly include trapezoidal thread screw, ball screw and planetary roller screw.

Trapezoidal thread screw: The spiral shape is an ordinary isosceles trapezoid. There is surface sliding friction during transmission, and heat is significant during continuous operation. In addition, the transmission efficiency is also low, and it is generally suitable for applications with large loads but low work rotation and work system requirements.

Ball screw: The ball chain is used to perform rolling motion between the screw shaft and the nut, converting the rotational motion into linear motion. Since the balls are constantly circulating between the two supporting surfaces, mutual collisions and sharp turns occur. ends, resulting in high speed conditions, the efficiency of the screw transmission is reduced, and the noise is high. It is generally only suitable for applications with medium performance requirements.

Planetary roller screw: Driven by the rotation of the screw, through the spiral movement between the screw and the roller, the roller drives the nut to move linearly. Planetary roller screws are mainly composed of screws, nuts and rollers. Screws and nuts are multi-threaded. Planetary rollers are generally single threaded. Threading teeth are provided at both ends of the rollers to engage internal threads. Toothed crown. Transmission principle and planetary gear system. Likewise, the screw is similar to a sun gear. The rollers serve as planetary gears and the nuts serve as ring gears. As the screw rotates, the rollers perform a planetary movement around the screw. At the same time, the rotational movement of the screw is converted. in linear reciprocating movement of the nut thanks to the principle of transmission by screw.

Source: Bote Seiko official website, “Application Status of Planetary Roller Screw Electric Cylinder” Deng Qi, Tianfeng Securities Research Institute

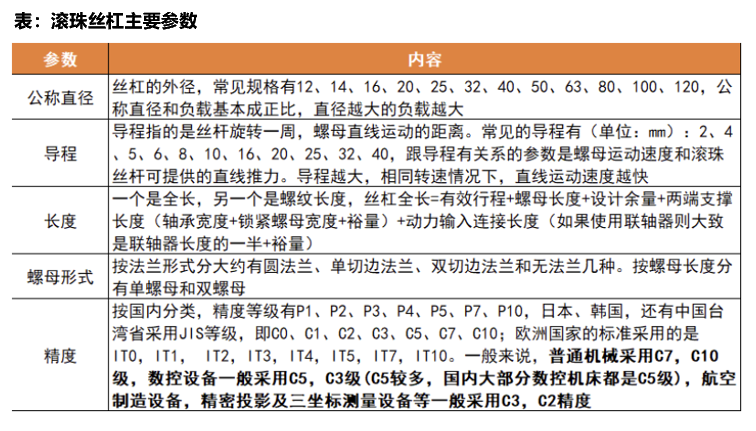

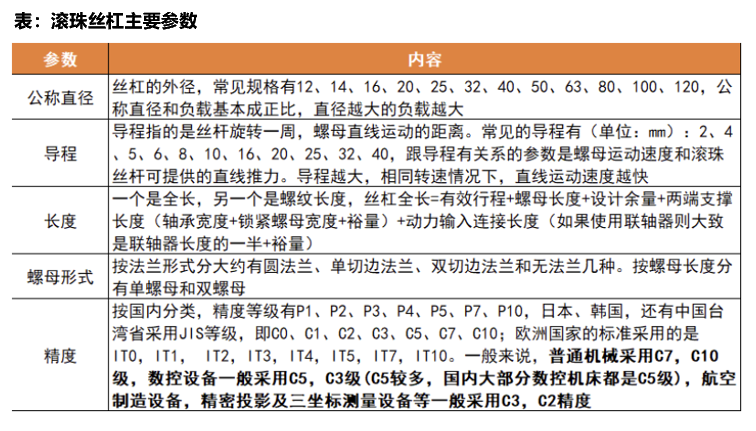

1.2 The main parameter of the screw is precision. The smaller the number under the JIS level, the higher the accuracy.

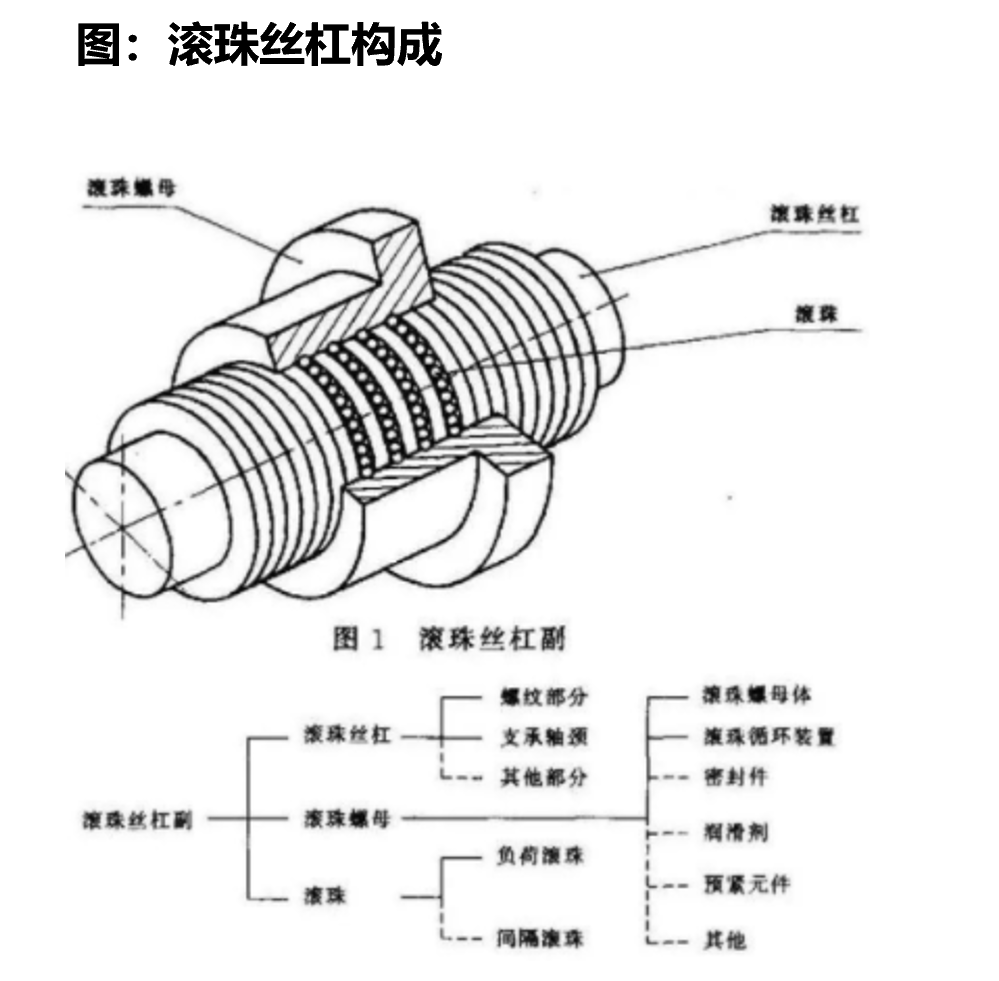

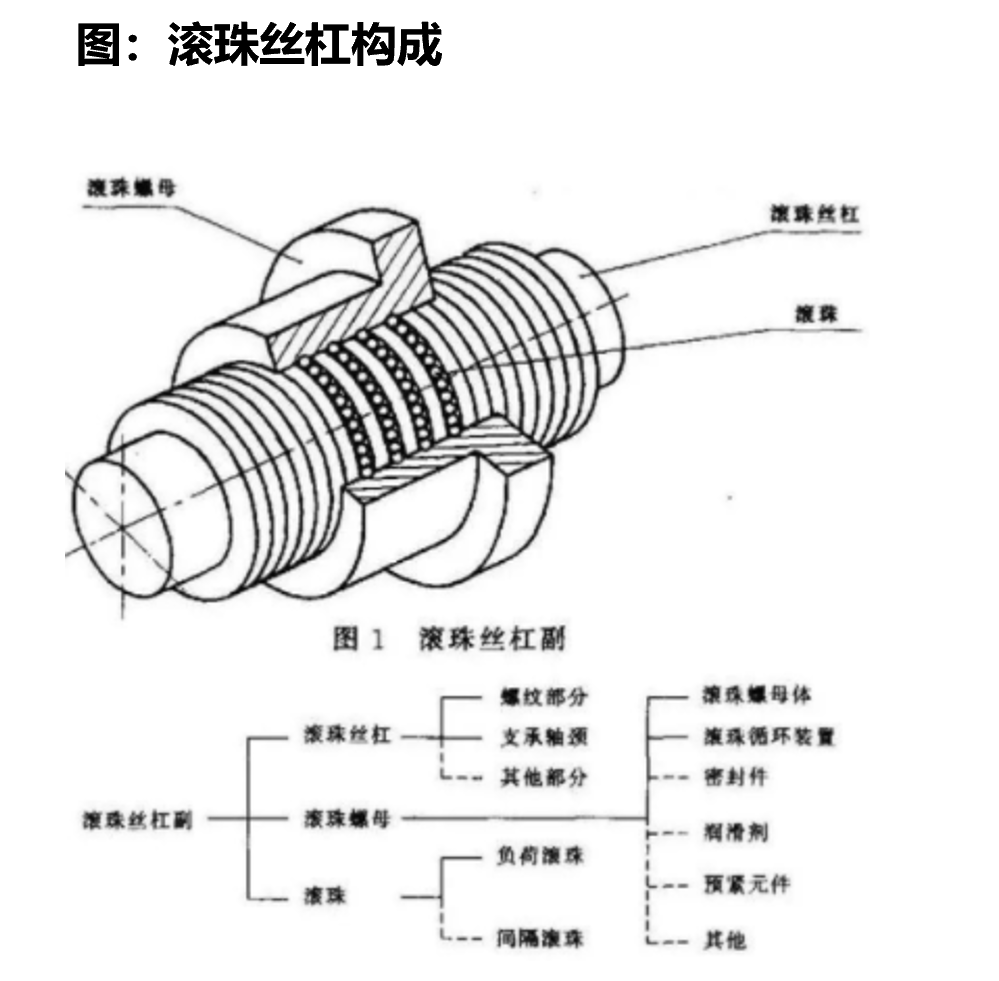

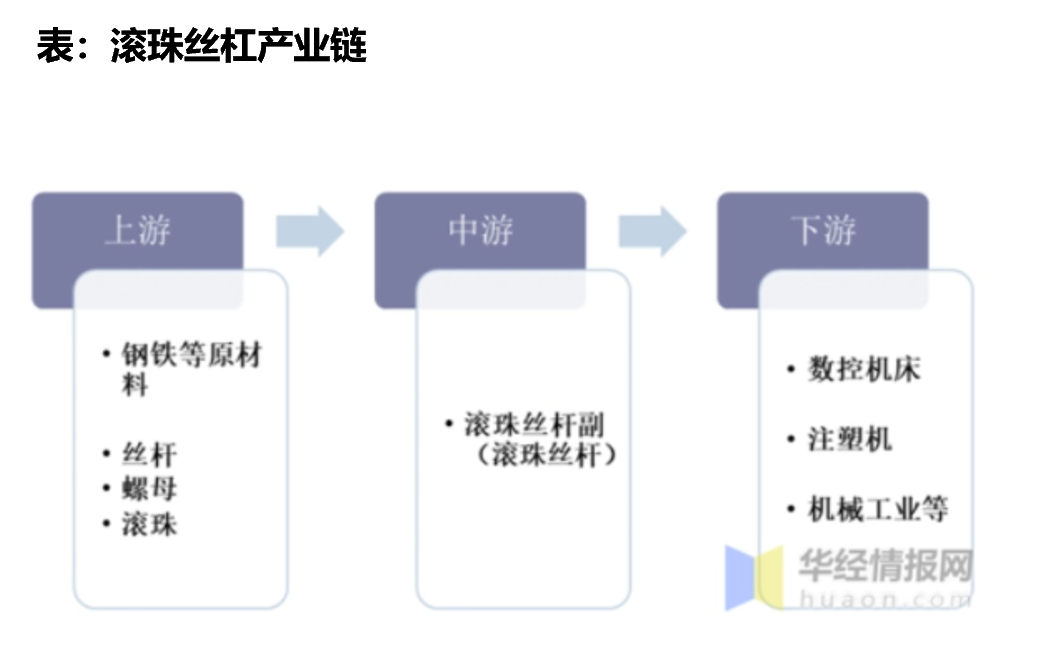

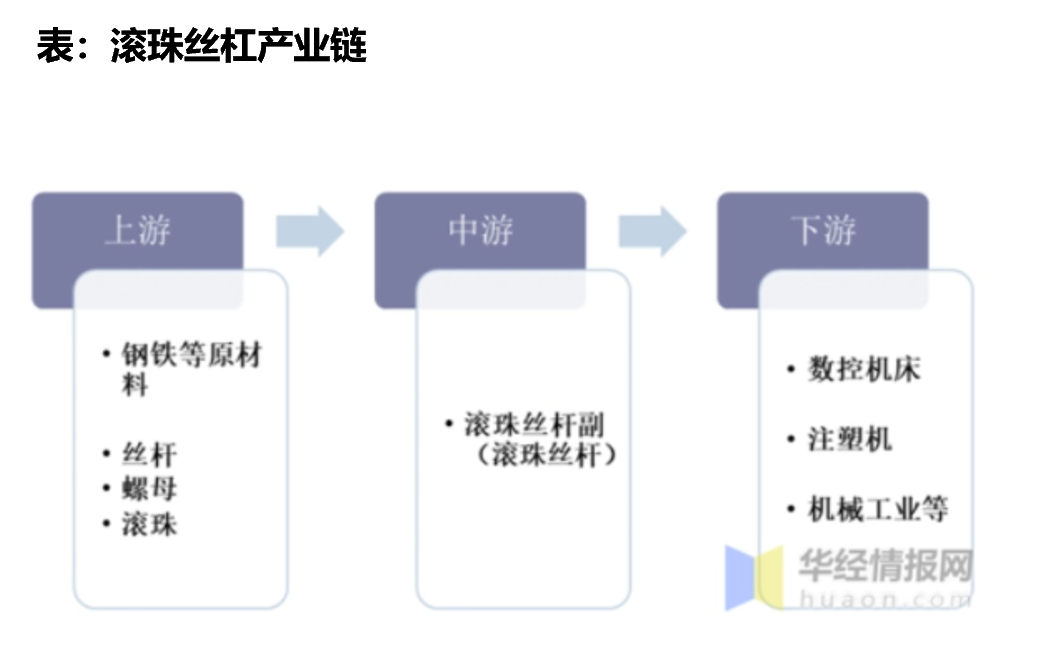

Ball screws are composed of screws, nuts, steel balls, pre-pressed parts, reversers and dust covers. These are common products in the industry. The main parameters include nominal diameter, pitch, length, nut shape and accuracy.

According to the national classification, the accuracy levels are P1, P2, P3, P4, P5, P7 and P10. Japan, South Korea and Taiwan Province of China adopt JIS levels, namely C0, C1, C2, C3, C5, C7. , and C10; Europe The national standards adopted are IT0, IT1, IT2, IT3, IT4, IT5, IT7 and IT10. Generally speaking, ordinary machines adopt C7, C10 level, CNC equipment generally adopt C5, C3 level (C5 is more, most domestic CNC machine tools are C5 level), aviation manufacturing equipment , precision projection and three-coordinate measuring equipment generally use C3, C2 precision.

Source: Metal Processing Public Account, Tianfeng Securities Research Institute

1.3 The transmission efficiency and precision of ball screws are significantly higher than that of trapezoidal screws

Transmission efficiency: The efficiency of sliding screw transmission is low, only 24%-26%; the efficiency of ball screw transmission is very high, up to 92%-98%;

Speed: The sliding friction of the sliding screw generates significant heat, and the general speed does not exceed 3000 RPS; the ball screw has point contact, and the rated speed is 3000-5000 RPS.

Pitch accuracy: sliding screws have low precision and uneven quality; ball screws are higher, but are often limited to millimeter levels by ball diameter.

Service life: The sliding screw has a short service life, and the sliding friction causes great damage to the components; The ball screw has a longer lifespan, just keep it clean and lubricated.

Micro-feeding: it is difficult to achieve with a sliding screw, and there is a crawling phenomenon in the sliding movement, it can be achieved with a ball screw, and the starting torque of the ball movement is small .

Self-locking: The sliding screw can self-lock, which is related to the angle of attack and the roughness of the working surface; the ball screw cannot self-lock and must be equipped with a braking device;

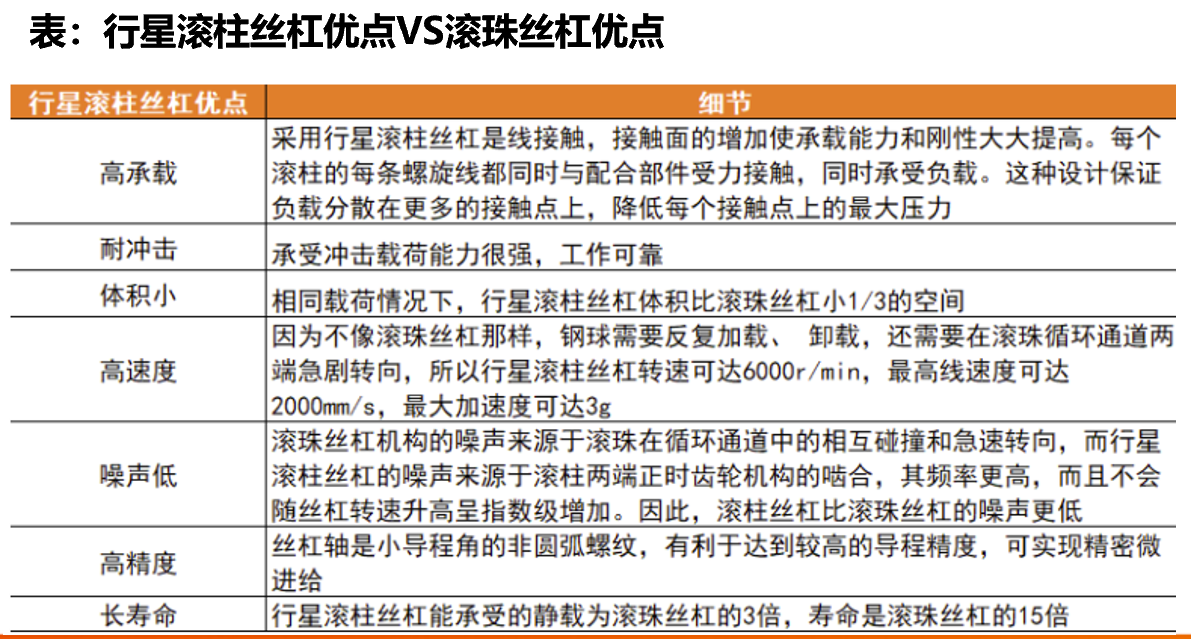

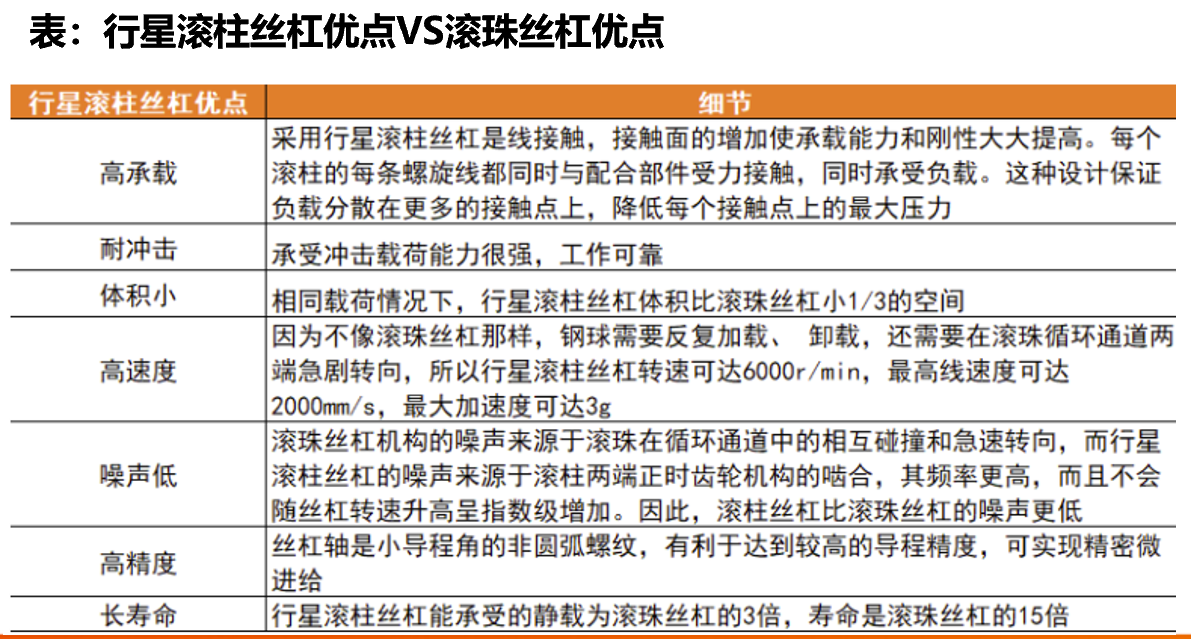

1.4 The advantages of planetary roller screws over ball screws mainly lie in impact resistance, load capacity and service life.

The rollers are in linear contact and the balls are in point contact. The load transmitting element of the planetary roller screw is a threaded roller, which is a typical linear contact, while the load transmitting element of the ball screw is a ball, which is a point contact;

The roller screw has better impact resistance, and its axial load capacity is 3-5 times that of the ball screw. Using threaded rollers instead of balls in a roller screw will allow the load to be quickly released through many contact points, resulting in greater impact resistance. The planetary roller screw mechanism combines the movement characteristics of a planetary gear train, a ball screw and a needle bearing. By arranging a number of planetary threaded rollers around the screw, the force contact area of the screw pair can be significantly increased. during the transmission process. The mechanism can withstand greater loads and impacts and has high reliability. Planetary roller screw drive is very suitable for high speed and heavy load applications.

The life of the roller is longer, more than 10 times that of the ball. For the same volume, the roller screw has a larger contact surface and evenly distributes the bearing force over a larger area. This reduces friction and extends service life.

Roller screws are less noisy than ball screws. The balls of the ball screw must change direction at a certain point on the roller table. The rollers and the main screw make circular movements synchronously, so the roller screw has less vibration and noise.

Source: Fang Yuanming Technology official account, Guanyan Report Network, Tianfeng Securities Research Institute

1.5 Planetary roller screws are subdivided into standard/reverse types. The difference lies in the different functions of the screw and the nut.

The planetary roller screw has 6 to 12 threaded roller screws arranged around the main threaded screw. The small threaded rollers used in the roller nut mesh with the main screw.

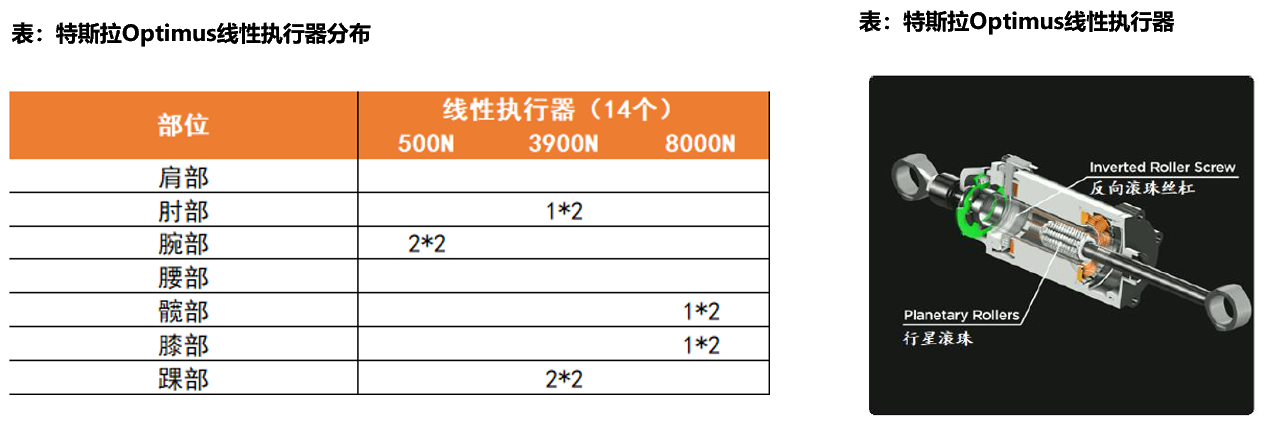

Planetary roller screws are classified based on their structure and movement characteristics, including standard planetary roller screws, inverted planetary roller screws (used by Tesla robots), circulating planetary roller screws and the differential planetary screws. Five types of roller screws and bearing ring planetary rollers. screw.

Standard planetary roller screw mainly consists of screw, roller, nut, inner ring gear, cage and retaining ring. The screw is generally used as the power input end and rotates only around its own axis; the nut is usually connected to the load and moves only along its own axis; the rollers carry out planetary movement and axial movement between the nut and the screw under the screw; screw action; the inner ring gear is fixedly connected to the nut, and the end teeth of the roller mesh with the inner ring gear to ensure that the rollers roll on the nut. is zero and they move axially with the nut.

The difference between inverted planetary roller screw and standard planetary roller screw is that the nut serves as a power input component and rotates around its own axis, and the screw serves as an actuator and moves along the axis. Gears are added at both ends; of the screw to replace the internal teeth. The ring meshes with the end teeth of the roller to ensure that the roller rolls on the screw. The roller and screw have no relative axial displacement and move together in the axial direction. The nut of the inverted planetary roller screw is the driving part and the screw is the output component. There is no relative axial movement between the roller and the screw. It is mainly used in application scenarios with low and medium loads, low and high strokes. Its maximum advantage is that its nut can be used as the rotor of the motor to realize the integrated design of the motor and the screw, forming a compact integrated electromechanical actuator.

Source: “Precision Analysis and Design of Planetary Roller Screw Transmission” Ke Hao, “Planetary Roller Screw Design” Wang Jiajian, Tianfeng Securities Research Institute

1.6 We estimate that the global ball screw market is about 10-15 billion yuan, with the main downstream sector being machine tools.

We estimate that the current global ball screw market space is 10-15 billion yuan, of which the domestic market accounts for about 20%. According to Qinchuan Machine Tool’s 22-year private placement prospectus: The global ball screw market is expected to reach 1.859 billion US dollars (about 13.6 billion yuan) in 2022, of which the ball screw market size of my country is about 2.77 billion yuan.

The sectors downstream of screws are mainly machine tools (representing more than 50%), industrial automation and automobiles. The machine tool transmission system must include two rolling linear guides and a pair of ball screws (a combination of a screw, a nut and several steel balls) to achieve precise movement. According to statistics from the China Machine Tool Association, China’s machine tool consumption in 2022 will amount to 27.41 billion US dollars. We assume that rolling functional components account for 10% of the value of machine tools (considering that the transmission system requirements of forming machine tools are high). lower than those of metal cutting machine tools), they can provide rolling functions. The market space provided by components (including screw + guide rail) is equivalent to RMB 18.4 billion.

Source: Huajing Information Network, 3rd Metal Processing Magazine User Survey on Rolling Functional Components, China Machine Tool and Tool Industry Association, Tianfeng Securities Research Institute

1.7 The global roller screw market space is 2 billion yuan, and humanoid robots are expected to significantly expand this market space.

At present, the global roller screw market is about 2 billion yuan and is mainly used in aerospace. According to persistent market research, the global roller screw market size in 2023 is around 300 million US dollars, and the domestic market size is around 13 million US dollars.

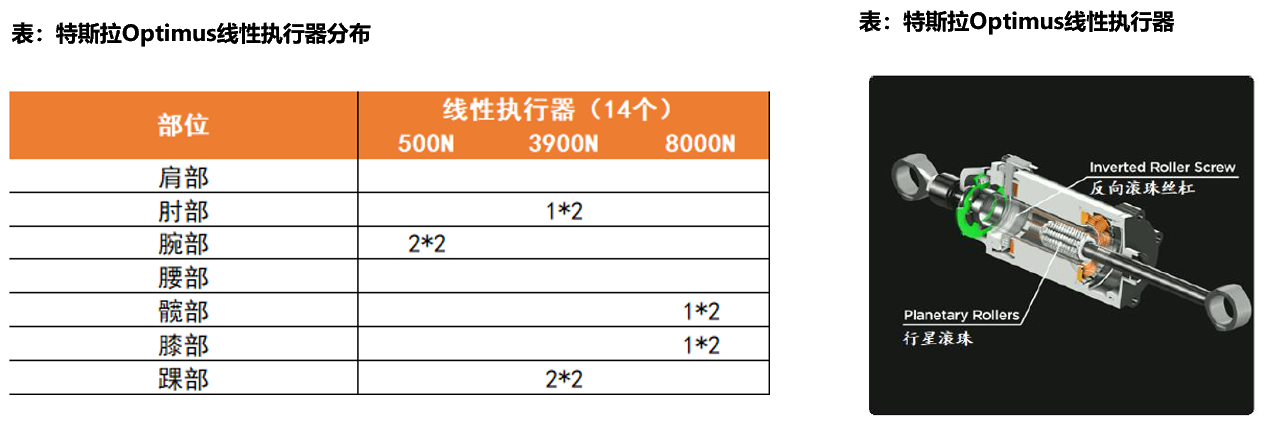

Tesla’s Optimus humanoid robot has 14 linear actuators. Linear joint actuators all use screws (rotary actuators use harmonics). According to the AI DAY video, most of them use planetary roller screws.

Considering that the role of the screw in the linear actuator corresponds to the harmonic reducer in the rotary actuator, we estimate that the future mass production price will be in the range of a few thousand yuan. We estimate that the corresponding unit price is 10, 50 and 1 million robots will cost 3000 yuan/unit, 1500 yuan/unit, 1000 yuan/unit, assuming that 10 of the 14 linear actuators use roller screws, the corresponding market space is 3 billion, 75 or 10 billion yuan. .

Source: Tesla AI DAY, Persistence Market Research, Tianfeng Securities Research Institute

2. There is a huge scope for domestic substitution in the screw industry, and the main obstacle lies in equipment and process know-how.

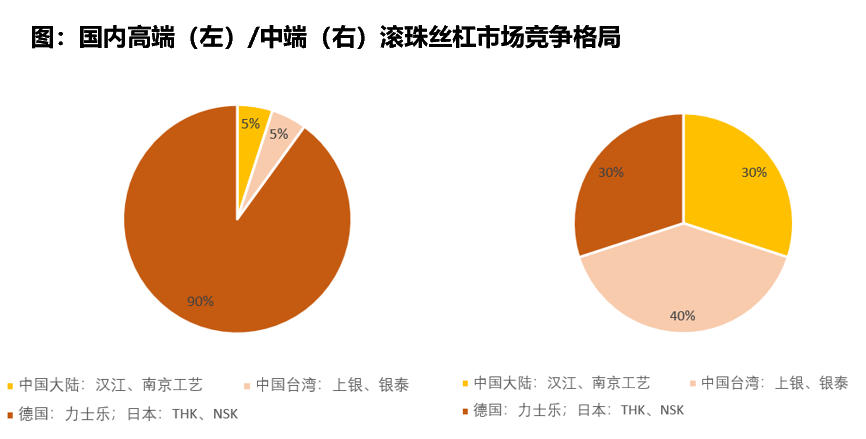

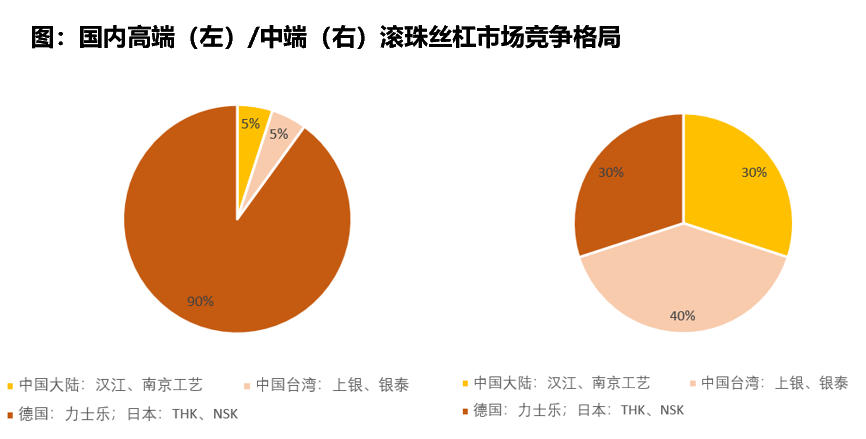

2.1 Ball screw head companies are mainly located in Europe and Japan, and the localization rate in the high-end market is low.

Looking at the global supply structure, the market share of CR5 from NSK, THK and others has reached around 46%.

Looking at the domestic supply structure, Shanghai Banking Group + Intime has a combined market share of almost 50%, and NSK and THK have a combined market share of 15%. Shanghai Silver Technology’s revenue in 2022 was 6.7 billion yuan (guide rails accounted for 64%, screws accounted for 22%), gross profit margin was 37%, and net profit was 1 billion yuan.

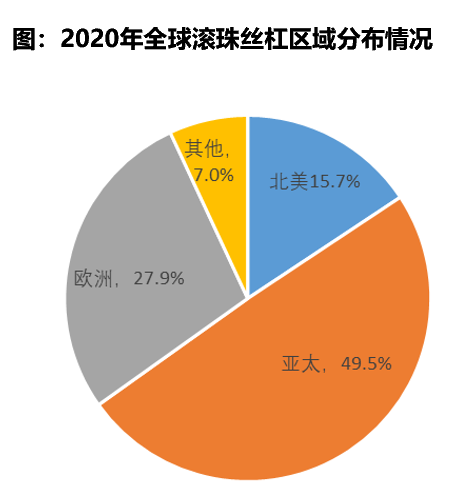

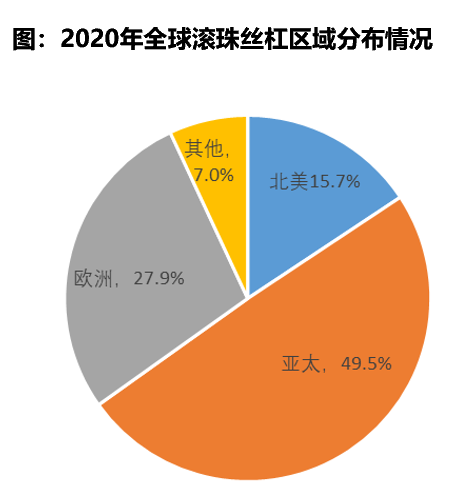

From the perspective of consumption region, the Asia-Pacific region is the leading global ball screw market. In 2020, the market shares in Asia Pacific, Europe and North America were 49.5%, 27.9% and 15.7%, respectively.

Source: Shanghai Silver Technology Annual Report, Metal Processing Public Account, Tianfeng Securities Research Institute

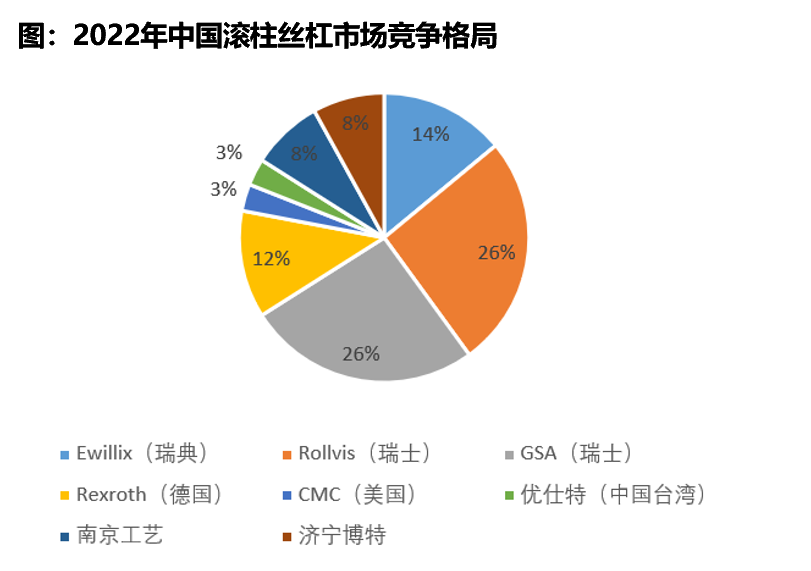

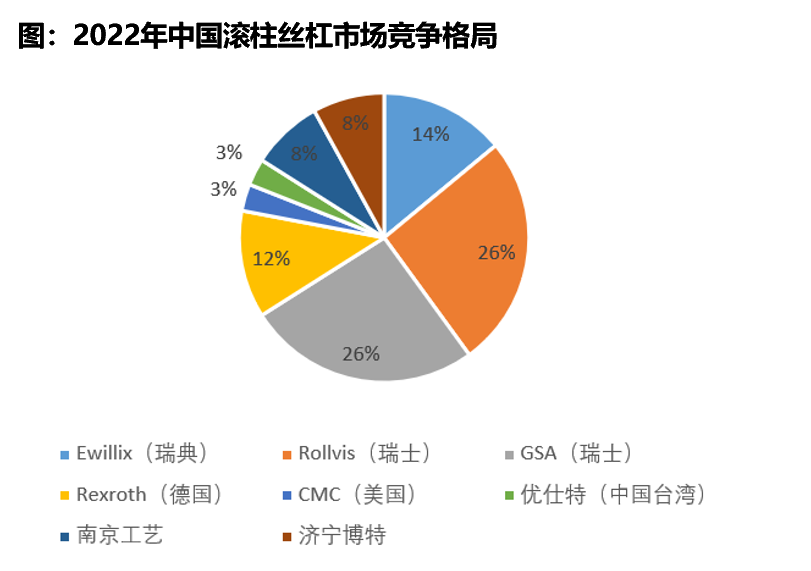

2.2 Foreign roller screws are all ahead of the domestic market. Typical leaders include the German Schaeffler, but domestically this product is still in its infancy.

The German Schaeffler, the American Exlar, the Swiss Rollvis, the Swedish company SKF, the Japanese NTN Co., Ltd. and other companies have formed a relatively mature planetary roller screw product system and set certain standards in terms of precision level, lubrication maintenance, application. platform, etc. The theoretical system has basically formed a technical monopoly in the field of planetary roller screws.

Schaeffler acquires Ewellix and becomes the absolute world leader in roller screws. Schaeffler is the global leader in bearings and linear motion products (revenue of 15.8 billion euros and EBIT of 974 million euros in 2022). On July 24, 2022, Schaeffler acquired the Swedish company Ewellix (the world’s leading provider of linear motion and drive solutions) for 582 million euros. Its main products are drives, ball screws, roller screws, etc., in 2021. Realized turnover of 216 million euros).

At present, the development of planetary roller screws by domestic manufacturers is still in its early stages. Although some manufacturers have successfully established small-scale production, the performance of their products still lags behind foreign products.

Source: “Research on Marketing Strategy of E Company Roller Screw Products” Wang Youxue, Schaeffler 2022 Financial Report, Schaeffler official website, Tianfeng Securities Research Institute

2.3 Ball screw manufacturing is divided into grinding and cold rolling. High precision requires grinding.

From the perspective of processing technology, ball screws are divided into ground ball screws and cold rolled ball screws.

Grinding ball screw: Using the center holes at both ends as a reference for the processing process, it is completed one by one by dozens of processes such as heat treatment, turning and grinding. It is suitable for positioning components for high precision equipment. ;

Cold Rolled Ball Screw: It is manufactured using cold working molds. The mold opening process is highly automated after mass production, the cost is low and the efficiency is high. However, manufacturing accuracy is not ideal and usually is. used as a transmission component in equipment.

Source: “Research on the regulation of precision ball screw machining process” Zheng Hong, Tianfeng Securities Research Institute

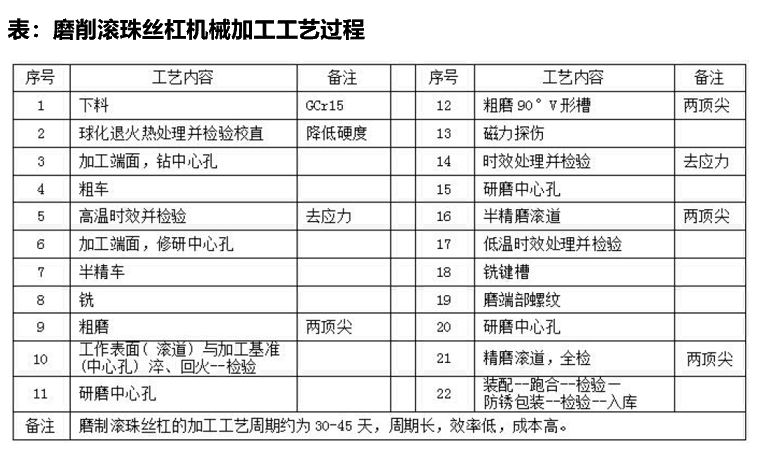

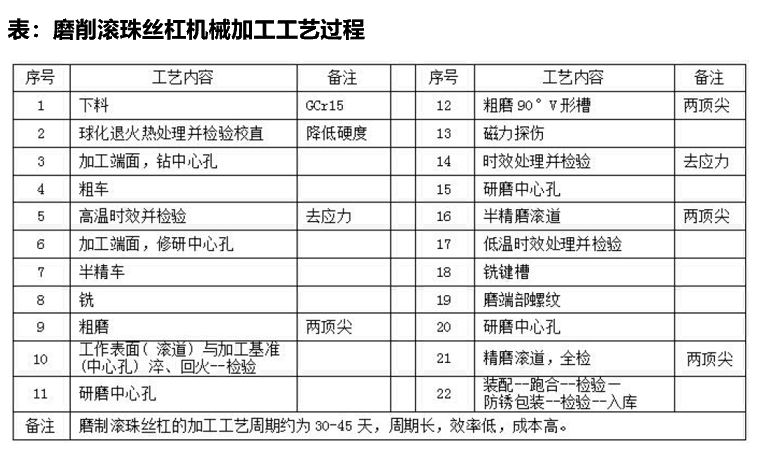

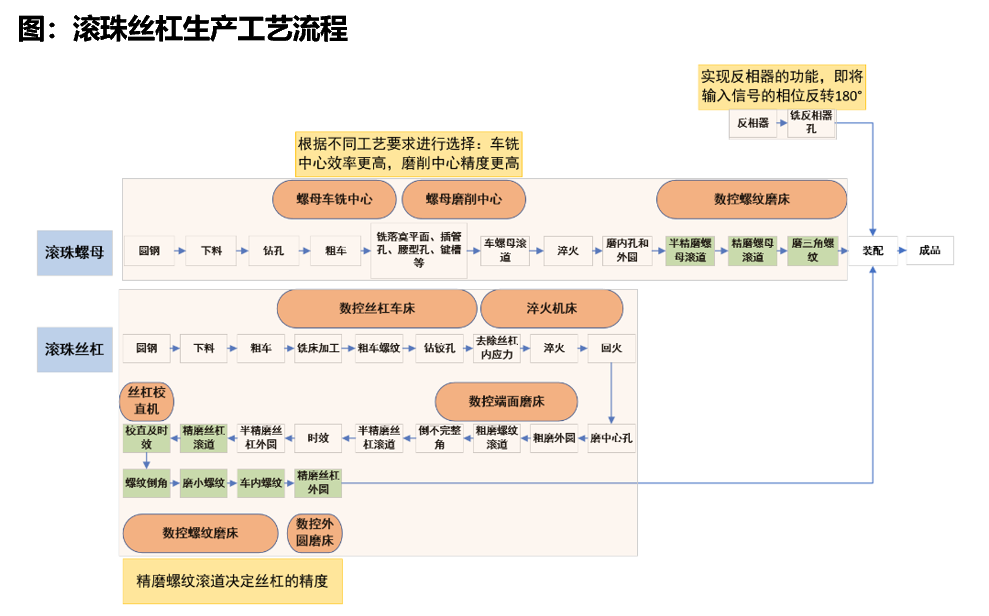

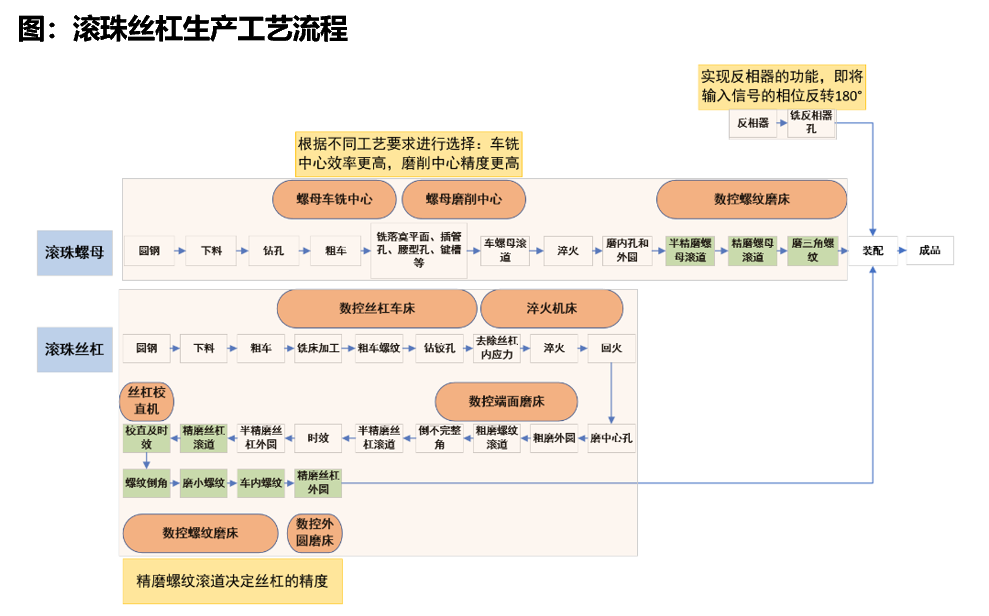

2.4 Grinding The main process of ball screw production is grinding, and high-end product equipment depends on imports.

The main production process of ball screws includes cutting, rough turning, coarse grinding, semi-fine grinding, thread turning, fine grinding and other processes. In addition, the production process also requires stress relief, quenching, tempering, straightening, etc. the part according to the customer’s needs. Surface treatment and other processes.

We believe that the essential part of screw production is grinding, and the basic equipment is the grinder. The well-known grinder supplier is Mitsui from Japan. There is still a big gap between domestic crusher equipment and imported crusher equipment. The basic equipment involved in the production of ball screws includes: 1) Grinding machine: including CNC thread grinder and CNC cylindrical grinder, used to grind the outer diameter, inner diameter and long diameter of the screw. Related companies operating grinding machines include Qinchuan Machine Tool (Hanjiang Machine Tool subsidiary), Rifa Precision Machinery, Shenyang Machine Tool, etc. 2) Lathes: including CNC lathes and milling machines, used for processing guide rods, nuts and threaded shafts. 3) Machine tools: Quenching machine tools are used for heat treatment. Heat treatment equipment (such as box furnaces, oil quenching equipment, quenching furnaces, etc.) improves the toughness, strength and wear resistance of the screw. Hengjin induction.

The production process and equipment of roller screws are almost the same as those of ball screws.

Source: Bote Seiko Environmental Assessment, Tianfeng Securities Research Institute

2.5 The technical barriers to CNC thread grinding machines are high, and domestic enterprises are in the catching-up stage.

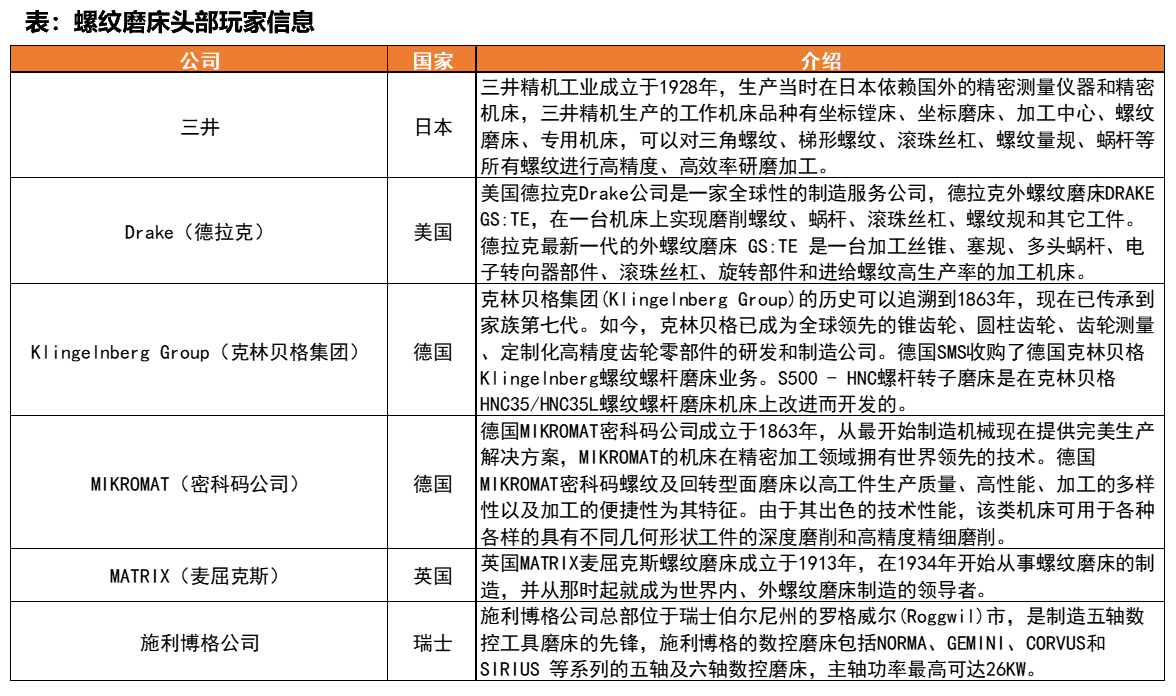

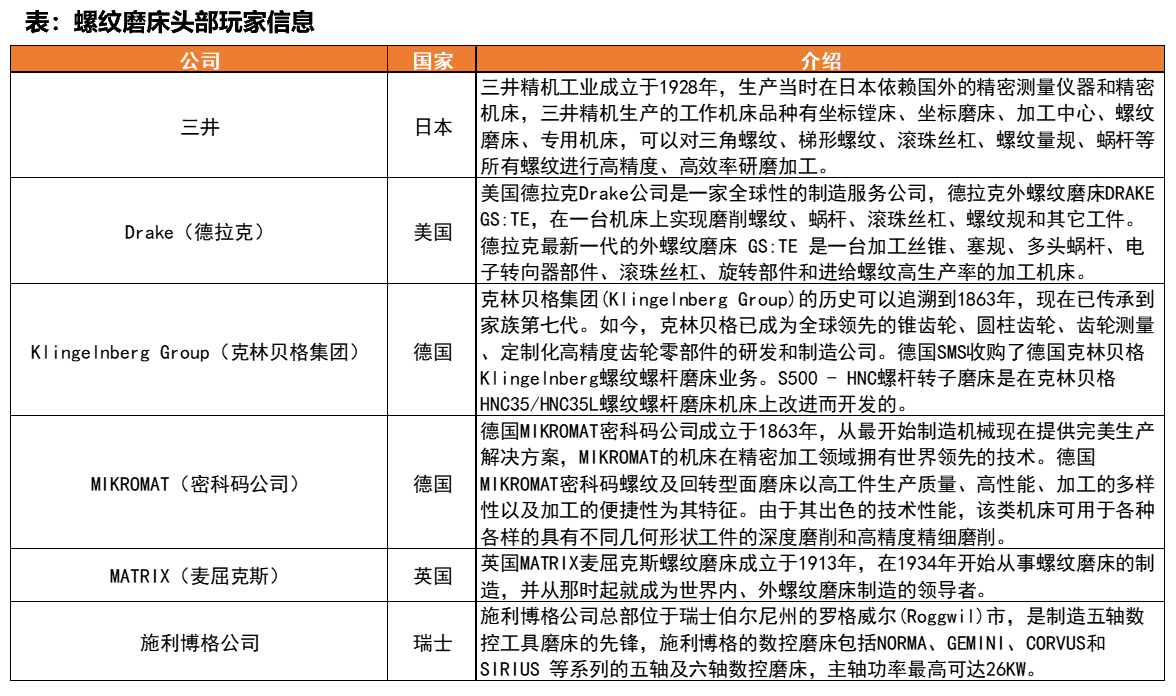

CNC thread grinder mainly includes machine bed, CNC device, servo system, grinding wheel dressing device, cooling circulation system, lubrication and protection system, etc. At present, domestic CNC thread grinding machines are still in the early stages of catching up with foreign players (major foreign players include Japanese Mitsui, German Klingenberg and American Drake, etc.).

The technical barriers of CNC thread grinders are: 1) The accumulation of thread grinding process and the foundations of grinding technology: involving the grinding conditions (such as the precision of the machine tool itself, the grinding wheels, clamping, cooling and lubrication systems, etc.) and grinding factors (stress deformation, thermal deformation and vibration, etc.); 2) Accumulation of online detection technology for machining precision in thread grinding process; 3) The main component CNC system is stuck abroad;

Source: Company official website, Tianfeng Securities Research Institute

2.6 Cyclonic milling instead of grinding is expected to reduce costs and improve efficiency, thereby providing growth opportunities for PCBN tools.

The rough machining method for grinding ball screw bearing races is divided into wheel grinding (the most commonly used), hard turning and cyclone milling. 1) Grinding wheel grinding: Using grinding wheel grinding to grind a 90° V-shaped groove has low production efficiency. 2) Hard Turning: Turning hardened materials is used as a new process for rough machining or final machining and finishing. It generally uses high cutting speed and large cutting depth. The metal removal efficiency is more than 3 times that of grinding. is very effective, but the disadvantage is that it is suitable for ball screws with a small aspect ratio. 3) Cyclone milling: milling the threads of the workpiece using a carbide forming tool installed on a high-speed rotating cutter head, with the highest production efficiency. The disadvantage is that it is suitable for ball screws with a high + length-to-diameter ratio. high precision is difficult to produce.

The commonly used equipment for grinding wheel grinding is a screw grinder or slot grinder. The latter two more efficient processes require the use of CBN cutting tools and CNC lathes.

The biggest advantage of cyclonic milling is its high efficiency (in theory it can be up to 10 times more efficient than traditional machining) and it does not require high technical requirements from workers (it uses forming blades).

High-efficiency production screws are of great importance for cost reduction in future markets such as robots. Schaeffler’s planetary roller screws currently sell for tens of thousands of yuan, and their grinding efficiency is low (the production cycle is 30-45 days. Therefore, high-efficiency production is of great importance for cost reduction).

Source: “Cyclone hard milling technology and its application in precision ball screw machining” Song Xianchun, “Research on regulations on precision ball screw machining process” Zheng Hong, Tianfeng Securities Research Institute

3. Investment advice

Under the trend of humanoid industry, we are optimistic about the location of mid-to-high-end screws, and it is recommended to pay attention to screws, equipment and consumables (tools).

The mid-to-high-end ball screw and roller screw markets are mainly monopolized by foreign giants. With the industrial trend of humanoid robots, there is a huge domestic substitution margin for mid-to-high-end screws. pay attention to:

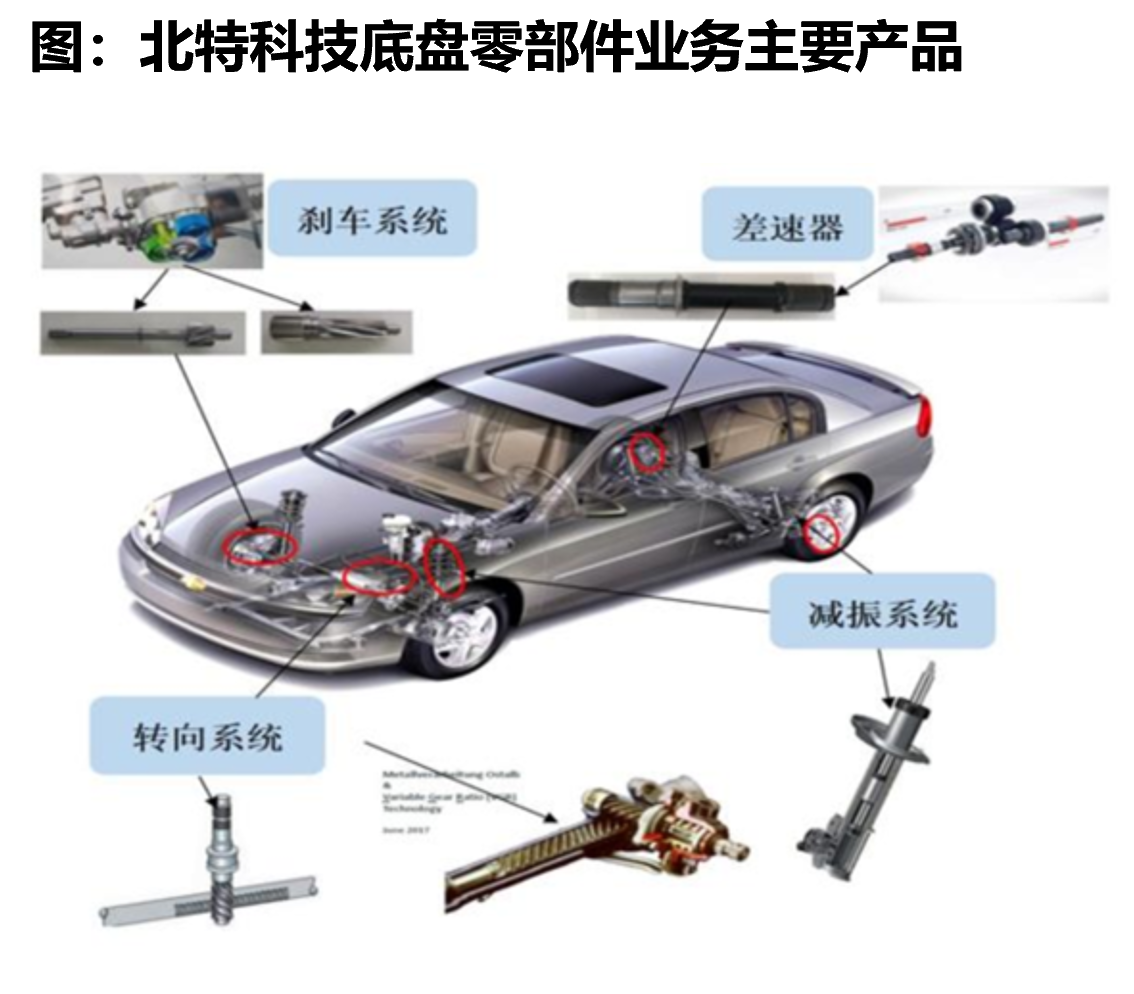

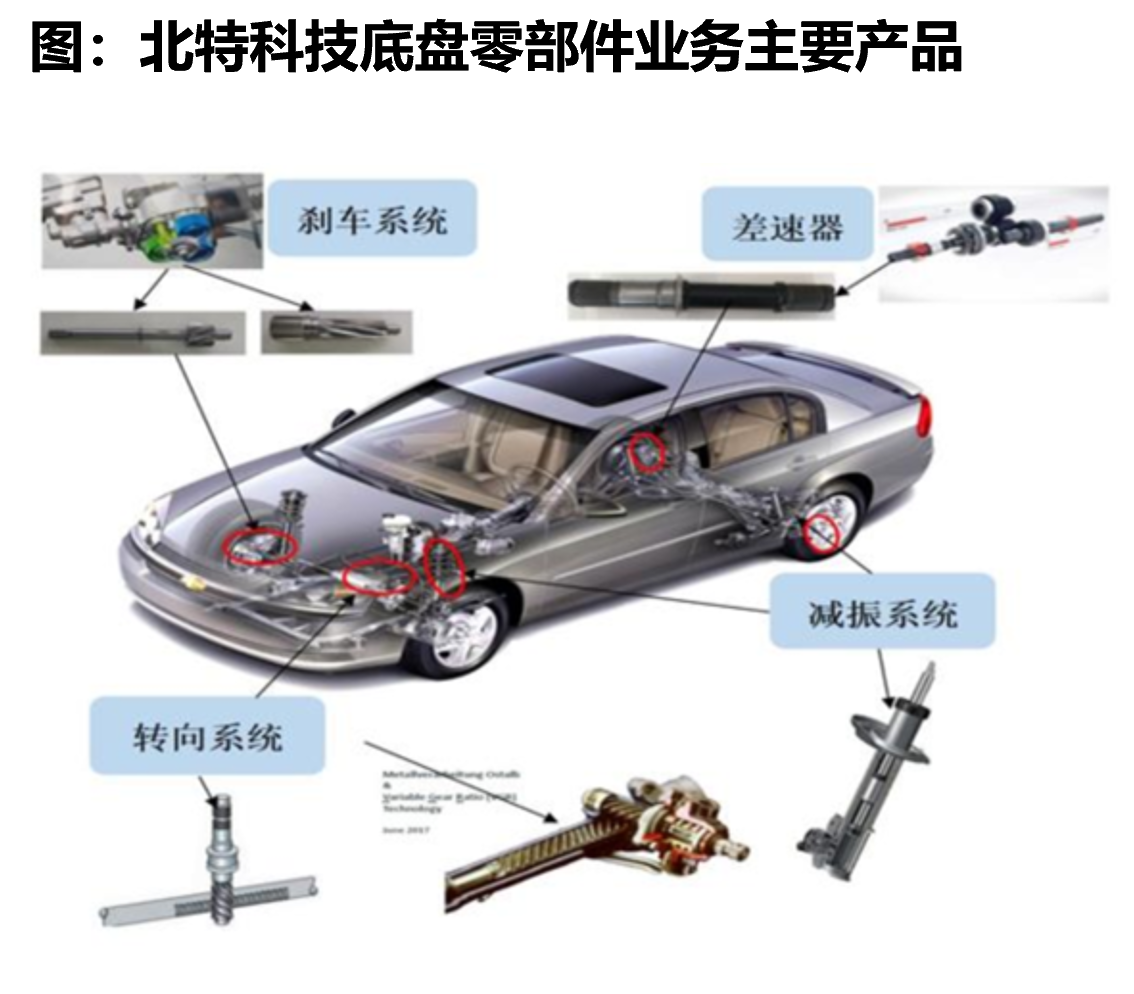

1) Screw: mainly engaged in automobile chassis parts,[Beite Technology]has accumulated a lot of know-how in precision machining, grinding, raw material packaging and surface heat treatment; the first equipment[le meilleur]advantages.

2) Equipment:[Huachen Equipment]a leading enterprise in the domestic roller mill industry, now has R&D and production capabilities for guide rails and screws; it specializes in high-end lathes and has the technology to replace grinding with cars. customer base includes Best, Wuzhou,[Zhe Heidemann]who sells Shuanghuan, etc. And[Rifa Precision Machinery]which already offers CNC thread grinder products;

3) Consumables: PCBN tool company[Wold]as part of the cyclone milling process.

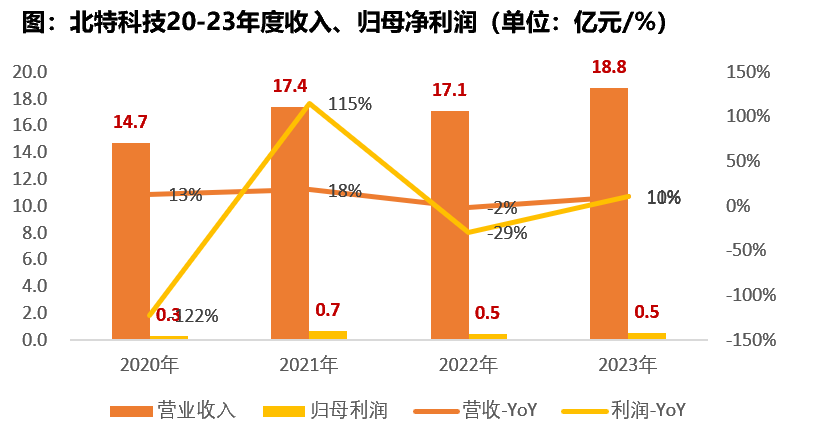

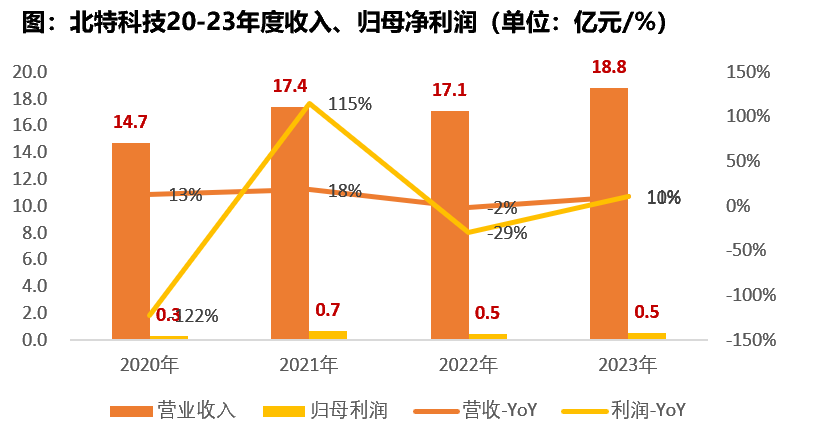

3.1 Beite Technology: Adhere to the dual-drive strategy that “auto parts business is the cornerstone and humanoid robot business is the future”

The Company’s main products include chassis parts, lightweight aluminum alloys and air conditioning compressors. The main products of chassis parts are steering racks, gears, shock absorber piston rods and wire brake IPB flanges, which are the main safety components of automobiles; core aluminum forging technology for lightweight aluminum alloys is mainly used in the direction of lightweighting new energy vehicles; In the air conditioning compressor industry, we are the largest OEM supplier of commercial vehicle compressors in China, with a full range of products, and our R&D and test verification capabilities are at the leading level in the field. country.

The company strategically attaches great importance to the humanoid robot industry, promotes the research and development of prototype screw products for humanoid robots, and at the same time promotes the construction of large-scale production lines of screw products for humanoid robots. According to the needs of Tier 1 automotive customers, it studies the use of lead screw products applied to automobile rear wheel steering (RWS) systems.

The advantages of Beite Technology for entering the screw market are: 1) Product synergy: The production process of automobile chassis parts and the production process of screw products have high homology. The R&D team specializes in precision turning, grinding and quality adjustment of raw materials. , surface heat treatment, defect detection, alignment and other aspects have formed a set of highly professional and systematic process flows and production plans 2) Collaboration with customers: The company is rooted in automobile chassis parts industry for more than 20 years and has established a relatively complete customer system with high quality and good market reputation, and the diversity of products makes it possible to share the company’s customer resources for each product , thereby reducing market development costs; 3) R&D advantages: The company’s high-speed cyclone turning is independently developed, and the related technologies have reached advanced levels domestically and internationally.

Source: Beite Technology Announcement, Tianfeng Securities Research Institute

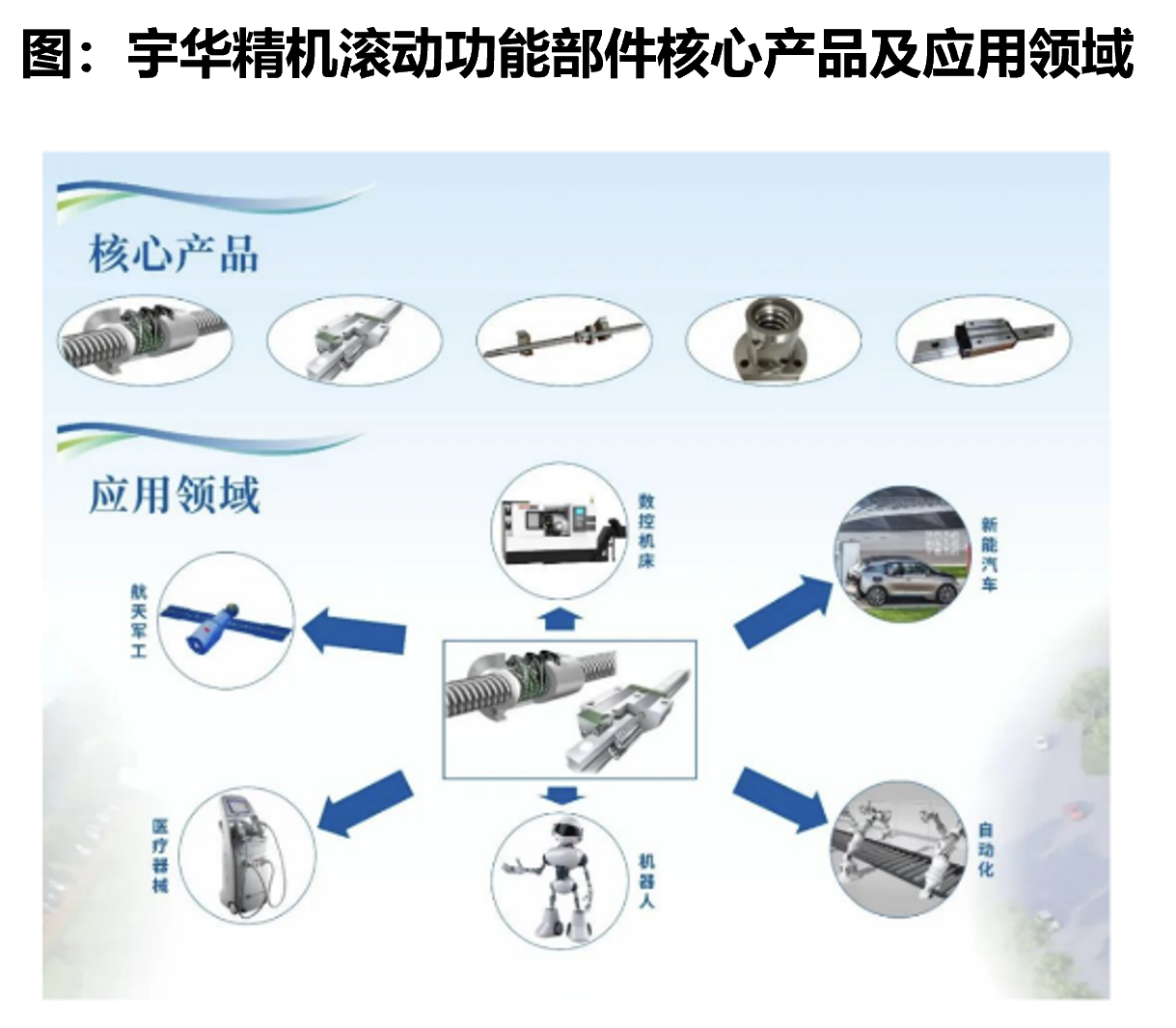

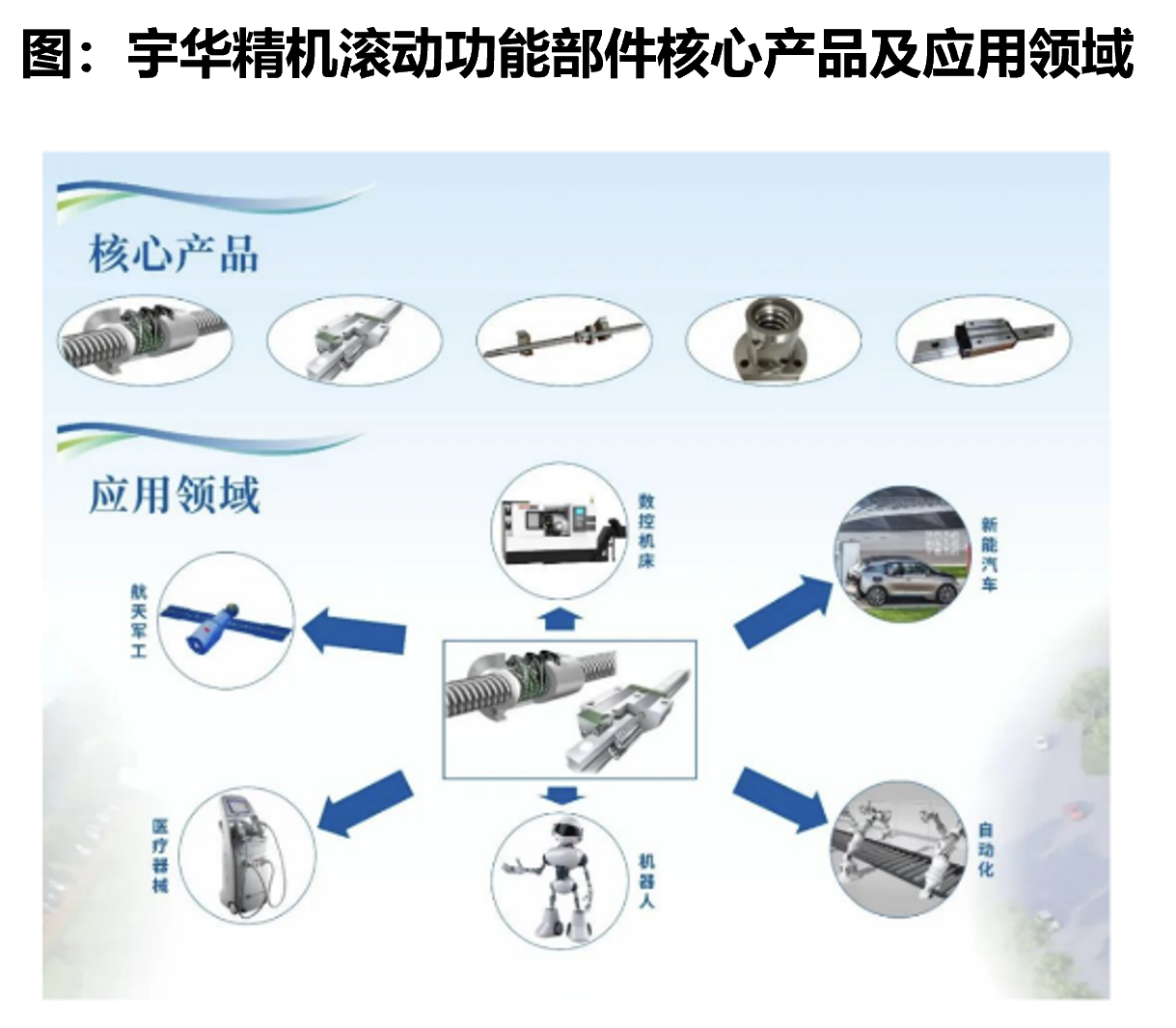

3.2 Best: Turbocharging industry is strong, new energy auto parts and ball screws open up the second and third growth poles

The company’s core business is strong (turbocharger parts revenue has increased by 10-15% in recent years) and the gross profit margin has been stable at around 35% for many years. The second growth pole (new energy vehicle parts) has begun to develop. volume increase in 2022, and the Anhui plant Under construction, the third growth pole ball screw is under development and is expected to gradually increase in volume over the following years.

In early 2022, a wholly-owned subsidiary, Yuhua Precision Machinery, was established to design functional linear bearing components, targeting machine tools, robots and other high-end markets. The project will introduce about 300 sets of imported production and testing equipment (including 70 sets of R&D equipment), more than 30 sets of software and supporting systems and public auxiliary facilities during 23H1, pairs of ball screws high precision, pairs of linear guides, etc. . were completed. The first set of products has rolled off the production line and samples have been sent.

We believe that Best’s advantages for entering the screw market are as follows: 1) Product process synergy: Ball screws involve precision machining + multi-channel processes, which are similar to the main business requirements of the company, that of turbocharged parts. experience in precision machining. More experience; 2) Customer Collaboration: Lead screw’s largest endorsement is machine tools, as well as automobiles. One of the major downstream markets, these two fields are the company’s current main products. The company maintains close relationships with major domestic engine manufacturers and complete vehicle manufacturers. 3) Equipment advantages: Ball screws/columns involve more imported equipment; The delivery time of the equipment is long, and the company takes the lead in arranging the equipment, providing a major advantage in equipment.

Source: Best Company Announcement, Best Official Website, Public Account of Wuxi Best Precision Machinery Co., Ltd., Tianfeng Securities Research Institute

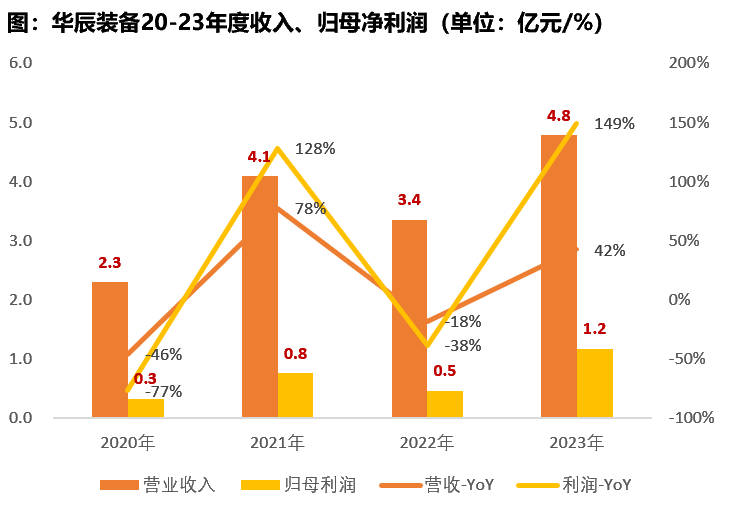

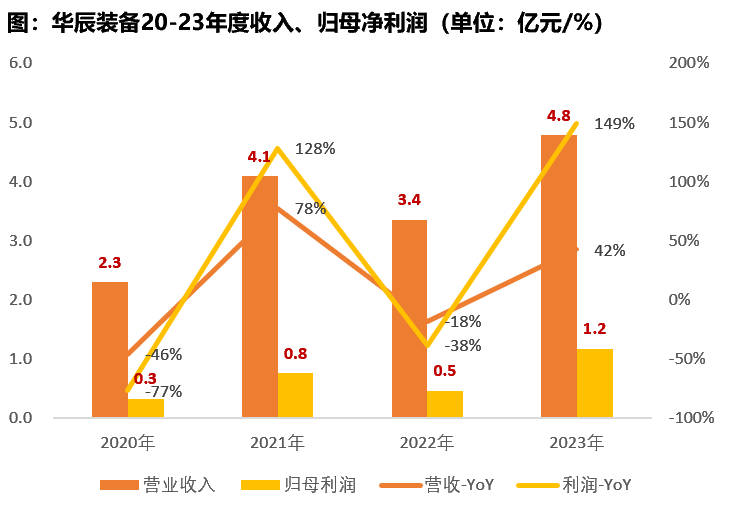

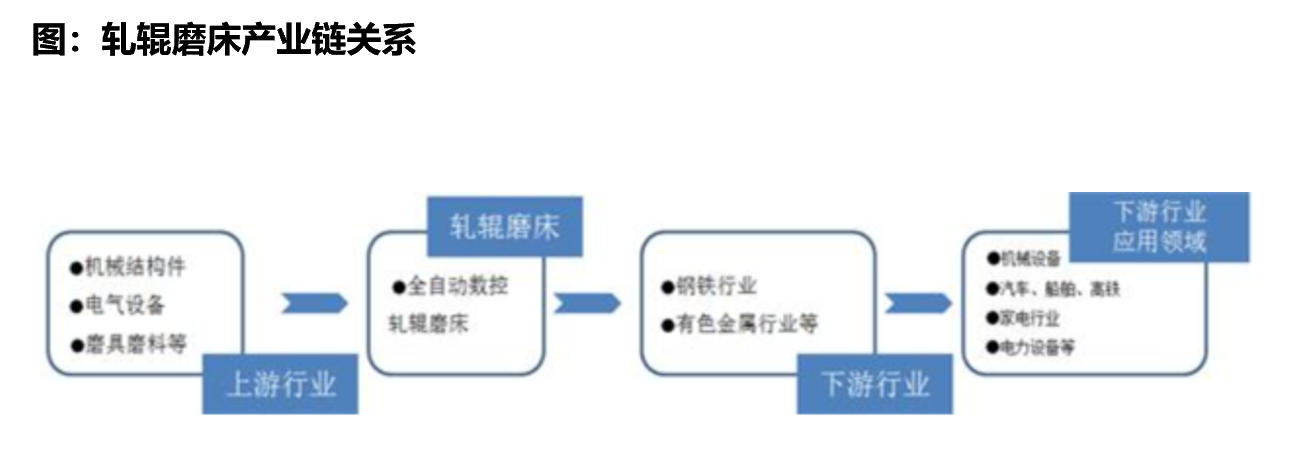

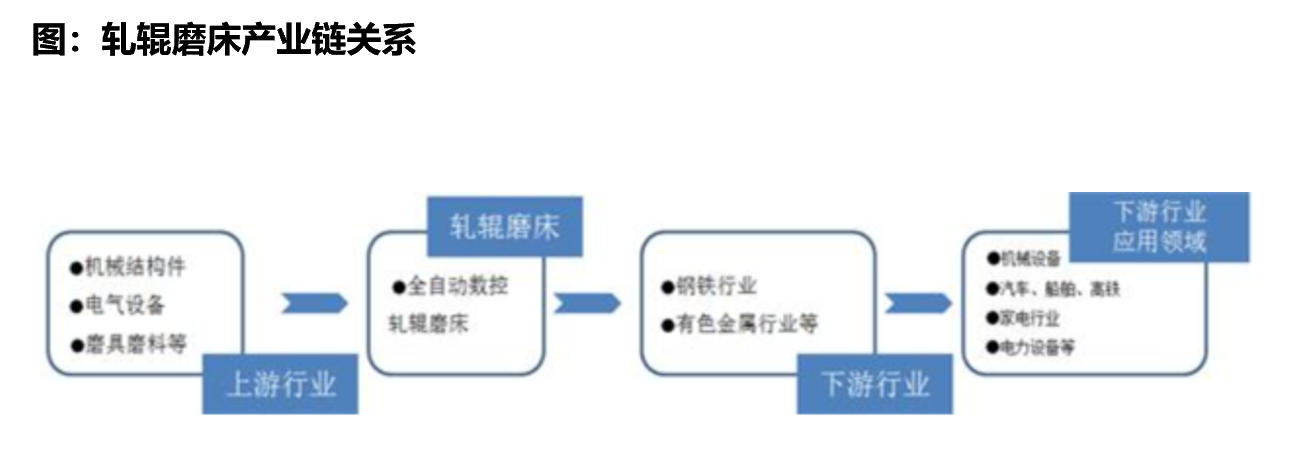

3.3 Huachen Equipment: A leading enterprise in the domestic roller grinder industry, it now has R&D and production capabilities of guide rails and screws.

The company’s main business is fully automatic CNC roller grinders and is a leading enterprise in the domestic roller grinder industry. Fully automatic high precision CNC roller grinder is an important supporting equipment specially used for precision roller repair. It currently represents the majority of the company’s revenue (representing 84% in 2023).

The company first mentioned precision thread grinders and CNC linear guide grinders in its 2023 annual report.

Precision thread grinder: Compared with world-class products, all precision indicators reach the same level as world-class products. The processing precision of standard screw samples ground by this product can reach P0 level. The products are widely used in industrial machinery, robot manufacturing, aerospace, auto parts manufacturing, equipment manufacturing, precision instrument manufacturing, etc.

CNC linear guide grinder: It can realize automatic grinding and automatic error compensation of linear guides. This product can provide high-precision, high-efficiency automated grinding processing for linear guide pairs of key equipment in industries such as industrial machinery, robot manufacturing, aerospace, automobile parts manufacturing and manufacturing of precision instruments.

Source: Huachen Equipment Company announcement, Huachen Equipment official website, Huachen Precision Equipment public account, Tianfeng Securities Research Institute

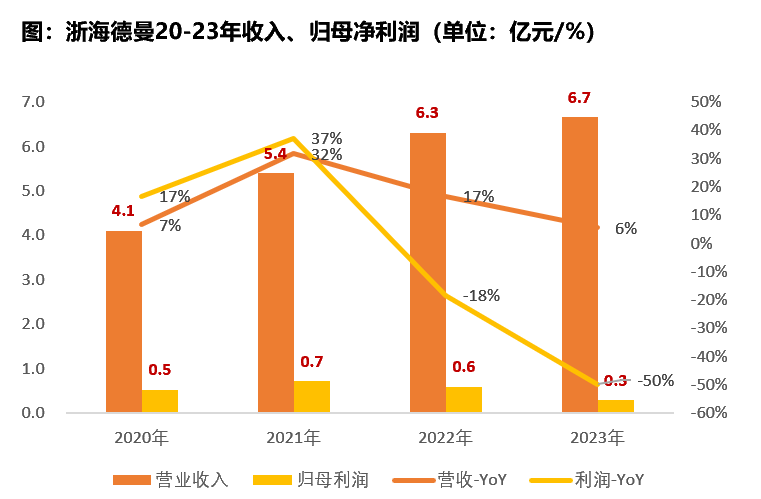

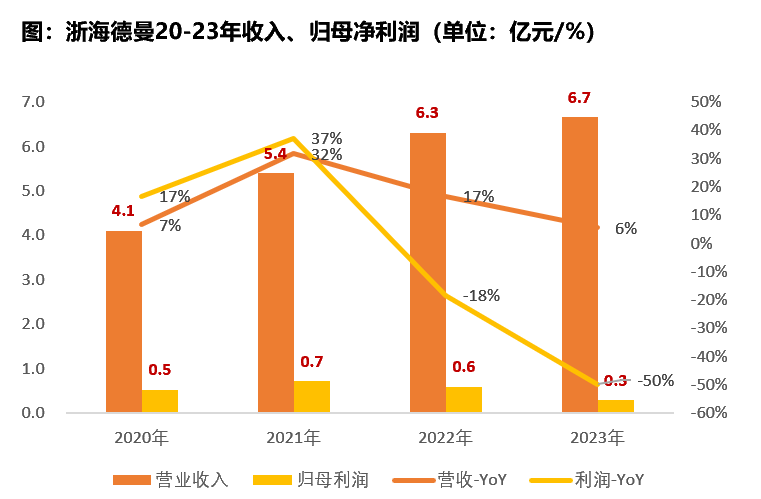

3.4 Zhejiang Heidemann: mainly engaged in high-end lathes, with the technology of using lathes instead of grinding, and its customer base covers Best, Wuzhou, Shuanghuan, etc.

The company’s main business is the research and development, design, production and sales of CNC lathes. Its downstream industries are automobile manufacturing, engineering machinery, general equipment and military industry. The company’s current products are divided into four categories: high-end T series CNC machine tools, automated production lines, parallel machining centers composed of turning and milling and ordinary CNC lathes. At present, the company has mastered the technology of high-precision CNC lathe spindles with spindle end runout less than 1 micron. In terms of industrial applications, 60% are mainly used in automobile manufacturing and 40% in engineering machinery, aerospace, general equipment, mold manufacturing, medical equipment and other industries.

The company’s customers include Best, Wuzhou Xinchun and Double Ring Transmission, and it has the technology to use cars instead of grinding. The company’s high-precision and high-rigidity CNC lathes have the important effect of replacing grinding with turning. Best, Wuzhou Xinchun, Double Ring Transmission, etc. have established cooperative relations with Heidemann for many years.

Source: Zhejiang Heideman Company Announcement, Zhejiang Heideman Official Website, Tianfeng Securities Research Institute

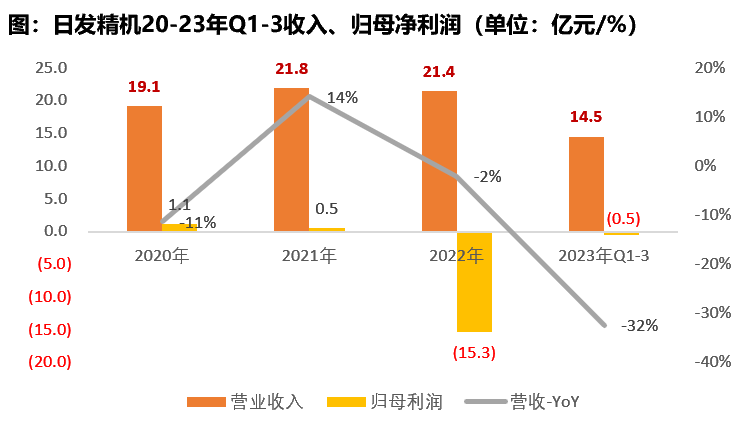

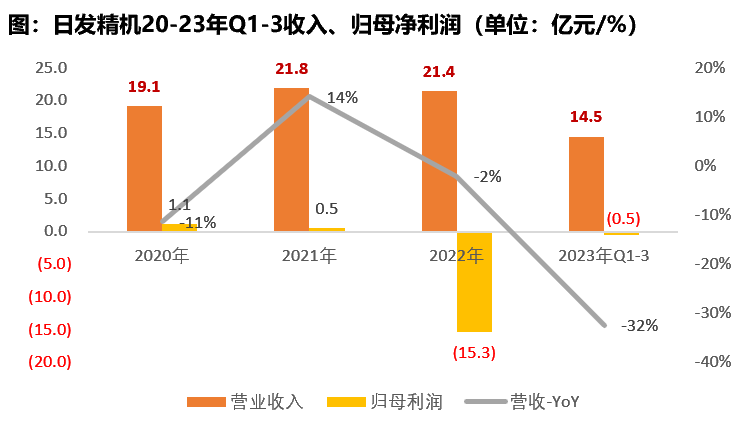

3.5 Rifa Precision Machinery: a leading domestic high-end CNC machine tool enterprise which will launch CNC thread grinder in 2023 and has made progress in market development.

The Rifa Machine Tool subsidiary is mainly active in mid-to-high-end CNC machine tools. Its downstream industries are high-precision machinery and parts manufacturing industries such as automobile, engineering machinery, agricultural machinery, petrochemical industry and railway transportation. Its products include bearing and ultrasonic CNC grinding machine tools and production lines, metal cutting CNC machine tools and production lines, including grinding, supermachining and High-end bearing assembly companies account for the largest share of the domestic market. The rate ranks among the best; Rifa Aviation Equipment is engaged in the processing and manufacturing of high-precision aerospace parts; Italian MCM is the world’s leading manufacturer of horizontal machining centers and has a technically advanced monitoring system. JFMX is engaged in the civil sector; aviation cargo aircraft Design, renovation, maintenance, rental and sales services. The company’s machine tools and digital intelligent production lines account for more than 50% of its revenue.

The company launched CNC thread grinder in 2023. CNC external thread grinder is mainly used for precision grinding of external threads of screws, worms, lead screws and other parts. CNC internal thread grinder is mainly used for outer circle, end face. and the arc of the ball screw nuts. Precision grinding consisting of internally threaded raceways. CNC thread grinders are used to process screw rods and nuts in industries such as new energy vehicles, humanoid robots and industrial machinery. At present, the company has made progress in market development. Cylindrical end grinders for nuts and internal and external thread grinders for screws and nuts have been delivered to customers. The Company will focus on following the technology development paths of downstream customers and end users of CNC thread grinders, and regard product research and development in related fields as the key future development direction.

Source: Rifa Precision Machinery Company announcement, Rifa Holdings official website, Tianfeng Securities Research Institute

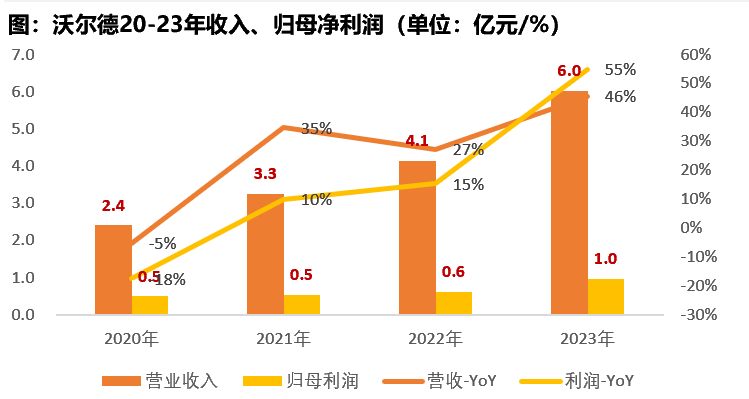

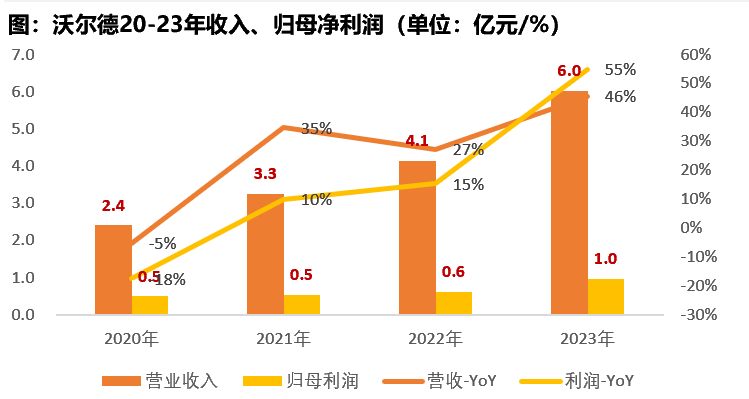

3.6 Wald: National leader in ultra-hard tool industry, PCBN tools use milling instead of grinding to efficiently process ball screws.

The company’s main business is cutting tools, cultured diamonds and CVD diamond functional materials, targeting the high-end market. Tool products include diamond grinding wheels, diamond grinding wheels, PCD/PCBN milling cutters, etc., and can develop and design more than 55,000 customized tools for customers; companies in China that can master the three major CVD method preparation processes, products include diamond membrane acoustic devices, diamond heat sink materials, etc.

PCBN (polycrystalline cubic boron nitride) is second only to diamond in hardness and has good thermal conductivity and wear resistance, high thermal stability and excellent chemical stability. It is an ideal material for cutting iron-based metals. PCBN cutting tools are mainly used for semi-finishing and finishing of high temperature alloys, hardened steel, chilled cast iron and other difficult-to-machine materials. Application industries include automotive, 3C, aerospace, new energy, engineering and general machinery. household appliances, etc.

Commonly used materials for ball screws are 42CrMo and GCr15. The hardness after heat treatment is between HRC58-62, and the geometric tolerance and dimensional accuracy of the processed part are strictly required. PCBN cutting tools have high hardness and thermal stability, and can effectively process ball screws by milling instead of grinding.

The company has developed a variety of brands for hard turning milling of ball screws. Products include forming knives, contour knives and chamfering knives, with a wide range of applications. Rotary milling inserts and PCBN cutting heads suitable for processing ball screws in high-end CNC machine tools and other fields have been supplied in batches, achieving market breakthroughs and profit growth operating.

Source: Wald Company announcement, Tianfeng Securities Research Institute

4. Risk Warning

The development of humanoid robots is lower than expected: progress in lead screw localization depends in part on the development and volume of humanoid robots. If the industry’s progress is lower than expected, it will affect the logical deduction of the full article.

The progress of Tesla’s humanoid robots is not as good as expected: The core of the development of humanoid robots depends on the development of Tesla’s humanoid robots. If Tesla’s progress is not as good as expected, it will affect the subsequent recommendation logic.

The entry of domestic suppliers into Tesla’s humanoid robot supply chain is less significant than expected: Tesla’s humanoid robots have not yet been mass-produced and suppliers have yet to be determined. This article discusses suppliers that could enter Tesla’s supply chain. Anything less than expected will affect our recommendation.

Progress in lead screw localization is lower than expected: many companies are deploying lead screws. If progress is less than expected, it will affect our vision.

Calculations are subjective: The calculations in this article are based on certain assumptions. There is a risk that the results of the calculations may be biased due to factors such as subjectivity, incorrect assumptions and less than expected market performance.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.