Invisible Engine: Precision CNC machining and driving New Zealand innovation

New Zealand. Amazing landscape, world-class agriculture and… cutting-edge precision engineering? Absolutely. Below the tranquility is a prosperous industrial sector that demands the absolute pinnacle of manufacturing capacity, especially Accurate CNC machining. This is not a simple metal puff. This is an invisible backbone of aerospace, medical equipment, marine technology, high-value electronics, and professional equipment that are crucial to our unique economy.

For manufacturers facing pressures of global competitive pressures, complex designs and strict quality requirements, the positioning of standard processing often means compromise. Complex geometric shapes shrink on drawing boards, stretching ahead of time and cost balloons. That’s the power of change here Advanced five-axis CNC machining Go into the spotlight and New Zealand, Great As a leader working to solve these exact challenges.

Why Precision CNC is the cornerstone of New Zealand’s manufacturing

Geographical isolation in New Zealand forces innovation and lean, high-value manufacturing. Accurate CNC machining can be done through:

- Overcome design constraints: Traditional 3-axis machines struggle with parts that require complex curves (such as impellers or turbine blades), undercut angles, composite angles, or features machining from multiple directions simultaneously. Five axis solves this problem.

- Ensure perfect accuracy and repeatability: High-tech fields such as aerospace and medical need tolerances measured in microns (µm) are much thinner than human hair. CNC machining provides this consistency after batch.

- Material versatility: From lightweight, powerful aerospace alloys such as titanium and inconel to complex polymers such as PEEK, as well as stainless steel to copper, New Zealand produces parts in different materials.

- Driving efficiency: Reduced setup, complex parts machining in a single operation, and minimized manual intervention translates into faster lead times and lower total cost of complex components.

- Enable Prototyping and Customization: Whether it is a one-time prototype for research and development breakthroughs or customized professional components, CNC provides flexibility for what NZ Innovators need.

Five-axis CNC: The game-changer

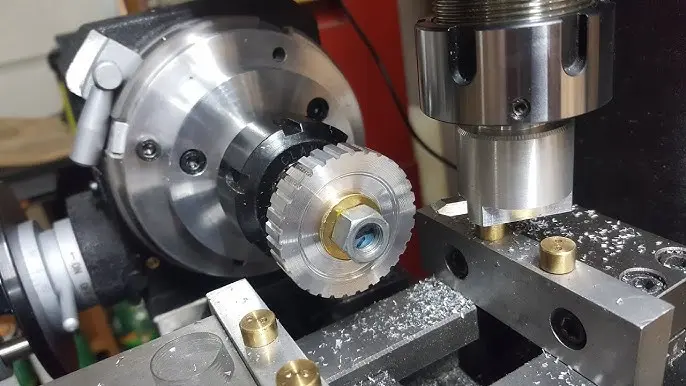

Go beyond traditional 3-axis machining (X, Y, Z linear motion), Five-axis CNC machining Add two axes of rotation (usually A and B) to the tool or workpiece. This creates near-boundary freedom of movement. Think of freely carving complex sculptures, not just chisels chiseled from the top and sides. The benefits are profound:

- Complex geometry mastery: Production of previously impossible parts or overly expensive machines in a single setup – deep cavity, engraved surface, organic shapes.

- Single setup solution: Processing functions from five aspects greatly reduce the need for multiple settings and fixes. A setting means:

- Save a lot of time: Eliminates the time spent repositioning parts.

- Cumulative error elimination: Each re-installation introduces the potential for misalignment. A single setting guarantees excellent position accuracy.

- Improved finish: Continuous tool paths on complex surfaces reduce witness lines and provide excellent final finishes.

- Best tool access and tool lifespan: Always orient the tool perpendicular to the workpiece surface for better cutting actions, reducing vibration and prolonging tool life – reducing costs.

- Shorter tools: The ability to work direction avoids the need for too long tools, improves rigidity and completion.

- Processing complex thin walls: Precise control of the cutting angle prevents deflection and vibration during delicate operation.

Greghime: Improve NZ’s precision manufacturing capabilities

Greglight is firmly at the forefront of providing these advanced capabilities in the New Zealand market. We know that accurate CNC is more than just machines. It’s about expertise, process and commitment to comprehensively addressing customer manufacturing challenges.

- Invest in advanced technologies: Our facilities have the most advanced Five-axis CNC machining center. This is not just hardware; it matches high-precision tools, detection systems (in-camera inspection for instant verification) and robust temperature control to ensure stability during machining – critical for micron-scale accuracy.

- Deep material expertise: New Zealand’s diversified industries require a variety of materials. Greatlight has the knowledge and proven process:

- Aviation alloy: Titanium (Ti6al4v), Aluminum (7075, 2024), Inconel.

- Stainless steel: 316, 304, 17-4ph.

- Engineering Plastics: PEEK, UHMWPE, DELRIN/ACETAL, PTFE.

- Appearance: Copper alloy (C101, C110), brass, special tool steel.

- Beyond the Machine: One-stop Precision: We go beyond the original processing. Our Comprehensive post-processing capabilities Make sure the parts arrive and are ready to be installed:

- Surface finish: Anodizing (engineering + decoration), painting, powder coating, bead blasting, polishing, passivation, heat treatment (pressure relief, hardening, cooling).

- Other processes: Precise grinding, engraving/marking, assemble (if needed), carefully packaged.

- Partnerships to solve problems: Gregmaind not only needs to receive orders; we work with engineers and designers. Our team provides Manufacturability (DFM) feedback designhelps optimize 5-axis efficiency, cost-effectiveness and performance design. We can solve complex manufacturing problems head-on.

- Quick customization and value: Do you need a prototype this month? Or special components designed for compaction specifications? GRESTLIGHT specialized research Custom precision machining delivers quicklyprovide competitive value while maintaining unswerving quality standards. Your precise parts are delivered on time on budget.

New Zealand Advantages: Greatlight right place

New Zealand manufacturers often operate in challenging niches – small batches, high value, complex, demanding quality. Outsourcing brings a lot of lead times, communication barriers, IP concerns and variable quality control. Greglight offers compelling local solutions:

- Reduce logistics and lead time: Local manufacturing means faster fulfillment and smaller minimum order quantity (MOQ) are feasible.

- Direct collaboration: Work face to face (or between screens) with the team that processes parts. Faster communication equals faster problem solving.

- Quality Assurance Control: Strict internal quality agreements ensure that parts meet the most demanding New Zealand and international standards. See the process for yourself.

- Support NZ innovation: Invest locally to fuel domestic high-tech industries.

Conclusion: Accuracy is not optional – this is essential

In demanding global markets, New Zealand businesses need manufacturing partners that can turn ambitious designs into accurate, reliable reality without compromise. Accurate CNC machining, especially advanced features of five-axis technology, is no longer an option. Maintaining competitive advantages in high-value fields is crucial.

Greglight embodies this commitment. Combined with tip Five-axis CNC machinerydeep technical expertise across different materials, and Comprehensive internal organization serviceWe provide seamless One-stop solution. We focus on effectively solving complex manufacturing problems and delivering Customized precision parts quicklyoffers extraordinary value in the context of New Zealand.

Whether you are developing next-generation aerospace components in Christchurch, groundbreaking medical devices in Oakland, Nelson’s engineering expertise in marine equipment, or advancing your complex ideas in high-tech agricultural technology in North Palmerston North, transforming your complex ideas into a tangible, advanced spiritual reality.

Stop letting manufacturing constraints limit your innovation. Work with New Zealand manufacturing leaders dedicated to precision, flexibility and partnerships.

FAQ: Priority CNC machining with Greatlight (New Zealand)

Q1: What exactly is it yes 5-axis CNC machining, why is it better than 3-axis?

A: Traditional 3-axis machining moves the tool up/down, left/right, forward/backward. 5-axis adds two rotation axes (such as tilting parts or tool heads). This allows for the machining of complex shapes in a single setup, changing the fixtures. Benefits include handling of complex geometries, faster production (less set-up), better finishes, longer tool life, and extremely high accuracy for complex parts. 3 axes are perfect for simpler parts; 5 axes unlock complex design freedom.

Question 2: Which parts and industries do you usually work with?

A: We specialize in complex, high-precision components in the following departments:

- aerospace: Bracket, housing, engine assembly (non-flight critical), instrument parts.

- Medical equipment: Surgical tool components, implanted prototype/fixture/fixture, diagnostic equipment parts (using biocompatible materials).

- Marine Corps: Customized prop components (usually prototypes), fluid system parts, instrument housing.

- Electronics and high-tech: Precise housing, radiator, communication components, specialized fixtures/fixes.

- Robots and automation: Arms, joints, final effectors, sensor mounts.

- Professional machinery: Custom components for agriculture, forestry and R&D equipment in New Zealand.

Q3: Which materials can be used as a Greatlight Machine?

A: We have processed a wide range of things, including:

- Metal: Aluminum (various grades), stainless steel (304, 316, 17-4ph), titanium (Ti6al4v), mild steel, brass, copper alloy (C101, C110), tool steel.

- Engineering Plastics: PEEK, PTFE (Teflon), Delrin/acetal, Nylon, UHMWPE, Polycarbonate, ABS, POM, PPSU.

- (Please consult composite materials or less common alloys).

Q4: My design is very complicated/habitual. Can you handle it?

one: Absolutely. Complex and custom parts are our expertise. We encourage sharing your CAD files as early as possible. Our expert engineers provide Manufacturing Design (DFM) Feedback, suggesting subtle adjustments (optimized undercut, wall thickness, functional access) can significantly increase production capacity, reduce costs and maintain quality No Destroy the functionality of the design. We see complex challenges as opportunities.

Question 5: Do you provide verification services instead of processing?

one: Yes, as part of our one-stop solution. We offer a comprehensive suite of Internal organization serviceincluding anodizing (various types/colors), painting, powder coating, bead blasting, polishing, passivation (for stainless steel) and heat treatment. We also offer grinding, engraving, assembly and careful packaging. This simplifies your supply chain.

Q6: How fast can you produce my parts?

Answer: Speed is a core component of our value proposition. Delivery times vary widely depending on the complexity of the parts, the required completions and the current workload. However, Being a local New Zealand manufacturer inherently offers significant speed advantages Go beyond overseas choices by eliminating shipping delays. We prioritize tight deadlines and provide realistic quotes within the scheduled lead time limit. Request a quote with timeline requirements.

Question 7: Can you consistently encounter stressful tolerances?

one: Our foundation is consistent with high precision. Maintaining micron level tolerances (usually +/- 0.01mm or more tight) is standard practice for advanced equipment that we operate by skilled technicians. We employ strict quality control procedures, including precise measurement equipment (CMM, micron), and often Real-time verification in-camera detectionmake sure each section meets your exact specifications, batch after batching. Ask about our project’s specific QC features.

Question 8: Why choose an NZ-based CNC machining partner, such as Greatlime, instead of an international choice?

A: Choosing Greatlight offers unique advantages:

- Faster communication and collaboration: No time zone delay, contact directly.

- Significantly reduce delivery time: No import/transport holding; faster quotes and delivery.

- Enhanced IP security and control: Keep your design and production in New Zealand.

- Easier quality supervision and face-to-face meetings: Promote accountability and partnerships.

- Support local economy: Invest in New Zealand manufacturing and innovation.

Customize precision parts in New Zealand with engineering expertise and speed. Get a free quote now.