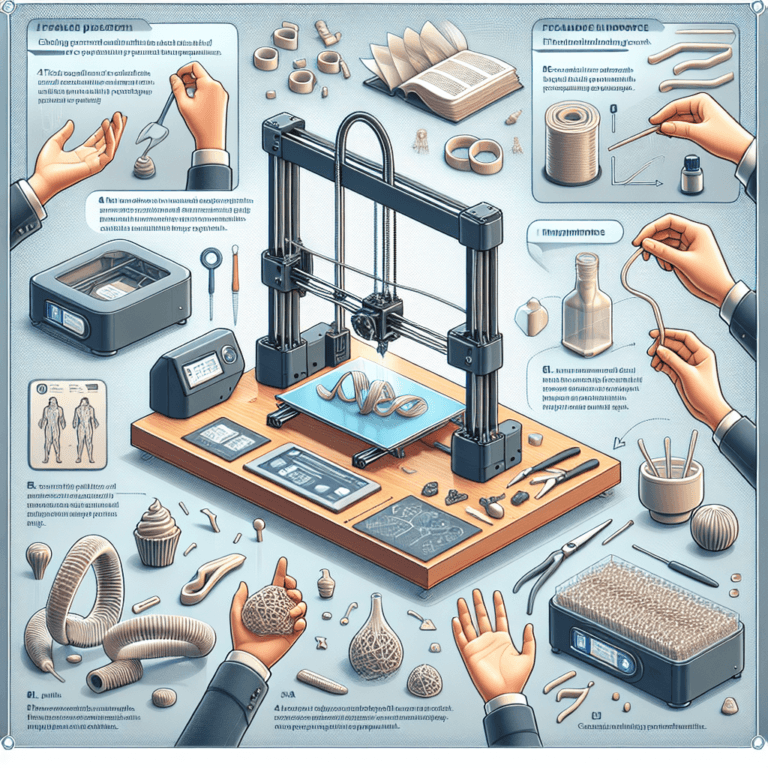

Introduction to Flexible Resin 3D Printing

As the world of additive manufacturing continues to expand, one area that has garnered significant attention is flexible resin 3D printing. This innovative technology has revolutionized various industries, enabling the production of structures that are not only intricate but also functional. In this article, we will explore what flexible resin 3D printing is, its applications, benefits, challenges, and how it differs from traditional printing methods.

What is Flexible Resin 3D Printing?

Flexible resin 3D printing utilizes photopolymer resins that possess elastic properties, allowing for the creation of objects that can bend and stretch without breaking. The process involves using a 3D printer equipped with a UV light source to cure the resin layer by layer. This method offers high-resolution outputs and intricate details that are difficult to achieve with conventional materials.

The resins used in this process are specially formulated to meet the demands of flexibility and durability, making them perfect for a variety of applications where traditional rigid materials fall short.

The Technology Behind Flexible Resin 3D Printing

Flexible resin 3D printing primarily uses two methods: Digital Light Processing (DLP) and Stereolithography (SLA). Both technologies leverage the same fundamental principle of curing resin with light but differ in how they project that light.

Digital Light Processing (DLP): This method utilizes a digital light projector to flash an entire layer of the object at once. It leads to faster printing speeds compared to traditional techniques because it cures one entire layer in a single pass.

- Stereolithography (SLA): SLA technology uses a laser to draw patterns onto the surface of the resin, curing it layer by layer. While this method typically offers more precise detailing, it can take longer than DLP due to the point-by-point curing process.

Both DLP and SLA have paved the way for efficient flow in flexible resin printing, allowing for enhanced speed and precision in producing high-quality 3D models.

Applications of Flexible Resin 3D Printing

The versatility of flexible resin 3D printing lends itself to a wide array of applications across different industries, including:

Prototyping: Engineers and designers utilize flexible resin to create prototypes that mimic the properties of final products. This helps assess design and function before moving to mass production.

Medical Devices: Flexible resins are often used in the production of medical devices, such as prosthetics and orthotics, allowing for comfortable wear and a custom fit.

Consumer Goods: Products like phone cases, watch bands, and wearable tech can all benefit from flexible resin due to its durability and aesthetic options.

Automotive and Aerospace: In these fields, flexible components such as gaskets, seals, and custom fittings can be designed to withstand various environmental pressures.

- Art and Fashion: Artists are leveraging flexible resin for unique designs and innovative fashion pieces, combining functionality with aesthetics.

Benefits of Flexible Resin 3D Printing

The popularity of flexible resin printing can be attributed to several significant benefits:

1. Customization

Flexible resin printing allows for high levels of customization. Designers can create tailored solutions that meet specific functional or aesthetic requirements, whether for biomedical applications or consumer products.

2. Complexity and Detail

One of the most notable advantages of flexible resin technology is its ability to produce highly complex geometries and intricate designs. This capability opens doors for innovation in various fields, from artistic expressions to functional engineering.

3. Strength and Durability

While flexible, the materials used in this process can also be incredibly durable and resistant to wear and tear. This makes flexible resin parts suitable for applications that require resilience, such as automotive components and sports equipment.

4. Speed

Thanks to advancements in printing technology like DLP, flexible resin 3D printing can be faster than traditional printing methods. Quick turnaround times for prototypes or final products are beneficial in fast-paced industries.

Challenges in Flexible Resin 3D Printing

Despite its many advantages, flexible resin 3D printing comes with challenges that must be addressed:

1. Material Cost

Flexible resins can be more expensive than standard rigid materials. This can be a barrier for smaller businesses or individuals looking to adopt this technology.

2. Post-Processing

Parts created through flexible resin printing often require extensive post-processing. This can include removing excess resin, cleaning, and curing, which can be time-consuming and labor-intensive.

3. Limited Build Size

Many flexible resin printers have limitations regarding build size. While technology is improving, large-scale applications may still necessitate multiple print jobs or larger equipment.

4. Learning Curve

Mastering the use of flexible resin printers can be daunting for beginners. Understanding the nuances of different resins, settings, and post-processing steps takes time and experience.

Comparing Flexible Resin Printing with Traditional Methods

When considering flexible resin 3D printing versus traditional methods of manufacturing, it is essential to assess key factors such as speed, cost, and material properties.

1. Speed and Efficiency

Flexible resin printing generally offers faster production times for complex geometries compared to traditional manufacturing methods, such as injection molding. Rapid prototyping capabilities allow for quicker iterations.

2. Cost-effectiveness

Though the material costs for flexible resins can be higher than for traditional plastics, the ability to create low-volume, custom parts can lead to overall savings in the product development lifecycle.

3. Material Properties

Traditional manufacturing often relies on rigid materials, which may not provide the desired flexibility in certain applications. Flexible resin printing allows designers to create products that can flex and withstand impacts, which may not be easily achievable with standard materials.

Conclusion: The Future of Flexible Resin 3D Printing

As the demand for customized, high-performance components continues to rise, flexible resin 3D printing will likely become an increasingly essential part of the additive manufacturing landscape. Along with continual advancements in printing technology, materials will evolve, expanding the scope of applications and enhancing performance.

For businesses and individual creators looking to embrace this innovative technology, understanding both its potential and challenges is critical. As flexible resin 3D printing continues to develop, it presents an exciting opportunity to push boundaries, leading to unique creations that blend practicality with innovation.

The potential of flexible resin 3D printing is vast and still largely untapped. By understanding its benefits and challenges, one can better navigate its complexities, leading to more informed decisions and successful applications within various industries.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.