Understanding the Basics of CNC Machining Costs

In today’s manufacturing landscape, CNC (Computer Numerical Control) machining stands as a cornerstone of precision production. Whether you’re a startup looking to prototype or an established company seeking to optimize your manufacturing process, understanding the costs associated with CNC machining is crucial. This guide delves deep into the factors that influence CNC machining costs and provides insights on how to make this technology more affordable for your business.

Before we dive into the specifics, it’s important to grasp the general cost landscape of CNC machining.

Global Cost Variations

The cost of CNC machining can vary significantly depending on your geographical location:

- In Europe, CNC machining costs typically range from $35 to $120 per hour.

- Chinese CNC machining shops, such as AT Machining, offer more competitive rates, ranging from $10 to $30 per hour for services spanning from 3-axis to 5-axis machining.

These price differences highlight the potential cost savings that can be achieved through strategic outsourcing. However, it’s crucial to consider factors beyond just hourly rates when making decisions about your manufacturing process.

Key Factors Affecting CNC Machining Costs

Let’s explore the primary elements that contribute to the overall cost of CNC machining:

1. CNC Machine Type and Associated Costs

The type of CNC machine used significantly impacts the cost of the machining process. Here’s a breakdown of typical costs for various CNC machines in China:

3-Axis CNC Milling

- Cost Range: $10 to $20 per hour

- Applications: Suitable for simpler geometries and 2.5D parts

CNC Turning

- Average Cost: $15 per hour

- Why It’s Less Expensive: CNC turning machines are generally less costly to purchase and easier to operate

4-Axis and 5-Axis CNC Machining

- Cost Range: $25 to $30 per hour (can be higher in some cases)

- Why It’s More Expensive: Increased tooling costs and operational complexity

European CNC Machining Prices (for comparison)

- 3-Axis Machining: $35-40 per hour

- Multi-Axis Machining: $75-120 per hour

The stark difference in pricing between Chinese and European machine shops underscores the potential for cost savings through outsourcing. However, it’s essential to weigh these savings against other factors such as quality control, shipping costs, and lead times.

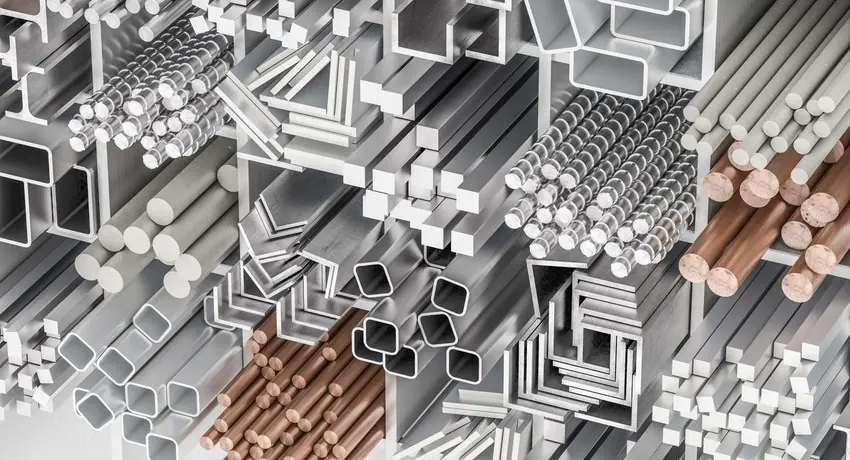

2. Material Machinability

The ease with which a material can be cut, known as machinability, plays a significant role in determining CNC machining costs.

Factors Affecting Machinability

- Physical properties of the material

- Softness and ductility of metal alloys

Cost-Effective Materials

- 6061 Aluminum

- Highly cost-effective for metal prototypes

- Offers a balance of low cost and good machinability

- ABS, Nylon, and POM (Delrin)

- Similar in cost to 6061 aluminum

- More challenging to machine, resulting in higher overall costs

Higher-Cost Materials

- Stainless Steel 303 and C360 Brass

- Higher material costs

- Better suited for high-volume production due to economies of scale

- PEEK (Polyether Ether Ketone)

- Very expensive

- Used only when absolutely necessary due to its specific properties

3. Design Complexity and Geometry

The complexity of your part’s design directly correlates with manufacturing costs. Complex designs often require:

- More advanced CNC machines

- Longer machining times

- Multiple setups

- Additional resources

- More rigorous inspections

Design Features That Increase Costs

- Sharp internal angles

- Deep cavities

- Thin walls

- Non-standard hole geometries

- Intricate lettering or textures

To optimize costs, it’s advisable to avoid these features unless they’re critical to your part’s functionality.

4. Production Volume

The relationship between production volume and unit cost is inverse – as volume increases, the cost per part typically decreases. This is due to several factors:

- One-time setup costs (CAD design, CAM programming, machine setup) are distributed across more parts

- Bulk material purchasing often leads to discounts

- Increased efficiency in production runs

Consider this when planning your production strategy, as larger orders can lead to significant cost savings per unit.

5. Finishing Operations

Post-processing operations can significantly impact the final cost of your CNC machined parts. Common finishing processes include:

- Anodizing

- Plating

- Heat treating

- Shot peening

- Electroplating

While these processes enhance the physical and mechanical properties of the part, they also add to the overall cost. If your application doesn’t strictly require these treatments, opting for as-machined parts can lead to considerable savings.

Strategies to Reduce CNC Machining Costs

Now that we’ve explored the factors influencing CNC machining costs, let’s discuss strategies to make this technology more affordable for your business:

1. Optimize Your Design for Manufacturability

- Simplify geometries where possible

- Avoid unnecessary complex features

- Consult with manufacturing experts early in the design process

2. Choose Materials Wisely

- Select materials with good machinability when possible

- Consider the trade-offs between material cost and machining time

3. Consolidate Parts

- Look for opportunities to combine multiple parts into a single, more complex part

- This can reduce assembly time and overall part count

4. Leverage High-Volume Production

- If feasible, order in larger quantities to benefit from economies of scale

- Consider your storage capabilities and cash flow when making this decision

5. Explore Global Manufacturing Options

- Investigate reputable overseas manufacturers, particularly in regions like China

- Be sure to factor in shipping costs, lead times, and potential quality control measures

6. Invest in Simulation and Analysis

- Use CAD/CAM software to simulate machining processes

- Identify potential issues before they occur on the shop floor

7. Build Long-Term Relationships with Suppliers

- Establishing partnerships can lead to preferential pricing and improved service

- Consistent business often results in better overall value

Conclusion

Understanding the intricacies of CNC machining costs is essential for any business involved in product development or manufacturing. By considering factors such as machine type, material selection, design complexity, production volume, and finishing operations, you can make informed decisions that balance cost with quality and functionality.

Remember, the cheapest option isn’t always the best in the long run. Focus on optimizing your designs, choosing the right materials, and working with reliable partners to achieve the best value for your CNC machining needs. Whether you’re prototyping a new product or scaling up for mass production, a thoughtful approach to CNC machining can lead to significant cost savings without compromising on quality.

By implementing the strategies outlined in this guide, you’ll be well-equipped to navigate the complex landscape of CNC machining costs and make decisions that benefit your business in both the short and long term.

The Ultimate Guide to 5-Axis CNC Machining Costs: Balancing Precision and Budget

In the world of advanced manufacturing, 5-axis CNC machining stands out as a pinnacle of precision and efficiency. However, with great capability comes potentially significant costs. This comprehensive guide will delve into the intricacies of 5-axis CNC machining costs, providing you with the knowledge to make informed decisions for your manufacturing needs.

Understanding 5-Axis CNC Machining

Before we dive into costs, let’s briefly explore what sets 5-axis CNC machining apart.

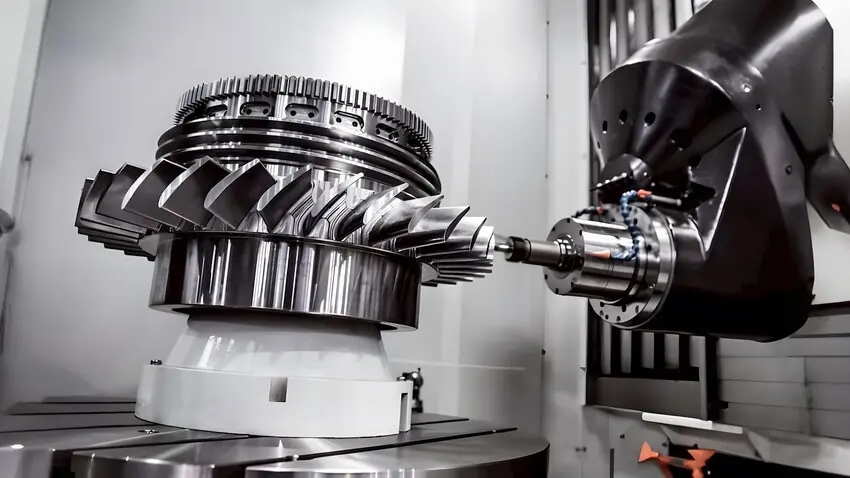

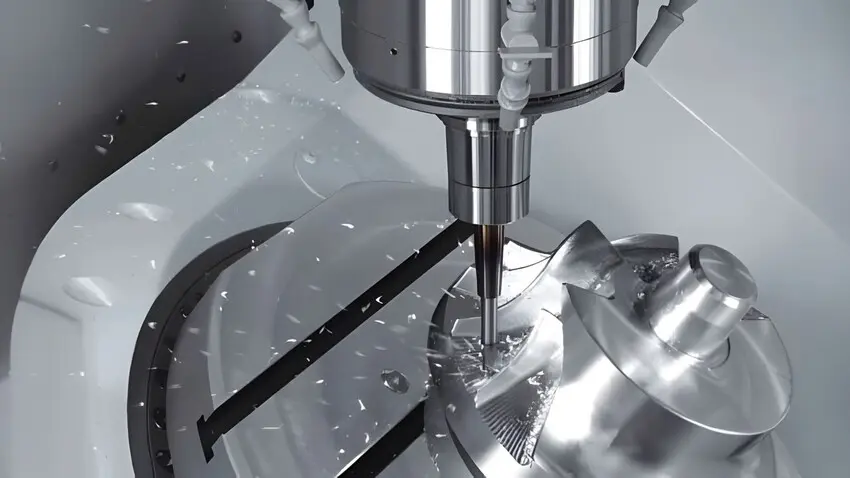

What is 5-Axis CNC Machining?

5-axis CNC machining refers to the ability of a CNC machine to move a cutting tool or part along five different axes simultaneously. This advanced capability allows for:

- Complex geometries and undercuts

- Reduced setup time

- Improved surface finish

- Higher precision

Why Choose 5-Axis CNC Machining?

Despite potentially higher costs, 5-axis machining offers several advantages:

- Single-setup manufacturing

- Ability to create complex parts

- Improved accuracy and surface finish

- Reduced labor costs for complex parts

- Shorter lead times for intricate components

The Cost Landscape of 5-Axis CNC Machining

When it comes to 5-axis CNC machining, costs can vary significantly based on numerous factors. Let’s break down the primary cost components:

1. Machine Costs

5-axis CNC machines are more expensive than their 3-axis counterparts, often costing between $250,000 to over $1 million. This initial investment is reflected in higher hourly rates.

2. Operator Expertise

5-axis machining requires highly skilled operators, commanding higher wages and increasing overall costs.

3. Programming Complexity

Creating toolpaths for 5-axis machining is more complex, requiring advanced CAM software and experienced programmers.

4. Setup Time

While 5-axis machining can reduce overall setup time for complex parts, initial setup can be more time-consuming and costly.

5. Tooling

Specialized cutting tools for 5-axis machining can be more expensive than standard tooling.

Average Cost Ranges

While costs can vary widely, here are some general ranges to consider:

- In Europe and North America: $75 to $120 per hour

- In China and other Asian countries: $30 to $50 per hour

Remember, these are just averages. Actual costs can be higher or lower based on specific project requirements.

10 Strategic Tips to Optimize 5-Axis CNC Machining Costs

Now that we understand the cost factors, let’s explore strategies to optimize your 5-axis CNC machining expenses.

1. Thoughtful Material Selection

Material choice significantly impacts machining costs. Consider these factors:

- Machinability: Easier-to-machine materials like aluminum can reduce costs

- Material cost: Balance between material price and machining time

- Application requirements: Don’t over-engineer if not necessary

CNC Machining Metal Comparison

CNC Machining Plastic Comparison

2. Optimize Design for 5-Axis Machining

Leverage the full potential of 5-axis machining in your design:

- Use organic shapes where appropriate

- Incorporate undercuts to reduce part count

- Design parts that take advantage of single-setup manufacturing

3. Consolidate Parts

5-axis machining excels at creating complex geometries. Use this to your advantage:

- Combine multiple parts into a single, more complex part

- Reduce assembly time and overall part count

- Minimize potential points of failure in the final product

4. Leverage High-Volume Production

While 5-axis machining shines for complex, low-volume parts, it can also be cost-effective for higher volumes:

- Amortize setup and programming costs over larger runs

- Negotiate better rates for long-term, high-volume projects

- Consider hybrid approaches, using 5-axis for complex features and 3-axis for simpler ones

5. Strategic Finishing Choices

Finishing operations can significantly impact costs. Consider these strategies:

- Use as-machined surfaces where possible

- Choose uniform finishes across the part when feasible

- Leverage the superior surface finish of 5-axis machining to reduce post-processing

6. Optimize Wall Thickness

Thin walls can be challenging and time-consuming to machine. For 5-axis machining:

- Aim for wall thicknesses of at least 1mm for metals and 1.5mm for plastics

- Use ribs or gussets for strength instead of uniformly thick walls

- Consider the cutting tool diameter when designing wall thicknesses

7. Design Appropriate Internal Radii

5-axis machining can create complex internal features, but certain design choices can optimize costs:

- Use filleted internal corners with a radius at least 1/3 the depth of the cavity

- Avoid sharp internal corners that require additional operations

- Design with tool accessibility in mind to minimize the need for specialty cutting tools

8. Optimize Pocket Depths

Deep pockets can be challenging even for 5-axis machines:

- Aim for pocket depths no more than 4 times the width

- Use stepped or tapered pocket designs for deeper features

- Consider how the part orientation in the machine can optimize tool reach

9. Smart Thread Design

Threads are often necessary but can be cost drivers. Optimize them by:

- Limiting thread depth to 3 times the hole diameter when possible

- Adding a non-threaded length of about 0.5 times the hole diameter at the end of blind holes

- Using standard thread sizes to avoid the need for custom tooling

10. Judicious Use of Tight Tolerances

While 5-axis machines are capable of high precision, tight tolerances increase costs:

- Specify tight tolerances only where functionally necessary

- Use standard tolerances (typically ±0.1mm) for non-critical features

- Consider using Geometric Dimensioning and Tolerancing (GD&T) to optimize tolerances

Advanced Strategies for Cost Optimization

Beyond these fundamental tips, consider these advanced strategies:

1. Hybrid Manufacturing Approaches

Combine 5-axis machining with other processes:

- Use additive manufacturing for complex preforms, then finish with 5-axis machining

- Combine 3-axis and 5-axis operations on the same part to optimize cost and capability

2. Invest in Simulation and Optimization Software

Advanced software can help optimize 5-axis machining processes:

- Use cutting simulation to identify potential issues before machining

- Leverage AI-powered toolpath optimization to reduce cycle times

- Invest in robust collision detection software to prevent costly errors

3. Explore Emerging Technologies

Stay abreast of new developments in 5-axis machining:

- Consider machines with integrated additive capabilities

- Explore cryogenic cooling for improved tool life and machining speeds

- Investigate high-speed and high-feed cutting strategies

Conclusion: Balancing Precision and Cost in 5-Axis CNC Machining

5-axis CNC machining represents the cutting edge of manufacturing technology, offering unparalleled capabilities for creating complex, high-precision parts. While the costs associated with this advanced process can be significant, strategic design and production choices can help optimize expenses without sacrificing quality.

By carefully considering material selection, design optimization, production volume, and advanced manufacturing strategies, you can leverage the full potential of 5-axis CNC machining while keeping costs in check. Remember, the goal is not always to minimize cost at all expenses, but to maximize value – creating parts that meet or exceed performance requirements while maintaining economic viability.

As you embark on your next 5-axis CNC machining project, keep these strategies in mind. Collaborate closely with your manufacturing partners, leverage their expertise, and don’t be afraid to think creatively. With the right approach, 5-axis CNC machining can be a powerful tool in your manufacturing arsenal, enabling you to create parts that were once thought impossible or impractical.

The world of manufacturing continues to evolve, and 5-axis CNC machining is at the forefront of this revolution. By mastering the balance between cost and capability, you’ll be well-positioned to take full advantage of this transformative technology.