Revolutionizing Manufacturing with the Next Generation of Machining Centers: Introducing the UBZ-NT Gantry Machining Center

In today’s fast-paced manufacturing landscape, manufacturers are constantly seeking ways to improve efficiency, quality, and flexibility while reducing costs. This is where advanced machining centers come in, and the UBZ-NT gantry machining center is at the forefront of this revolution. In this article, we’ll dive into the cutting-edge features and benefits of this innovative machine tool, designed to take your manufacturing process to the next level.

A New Era in Machining Technology

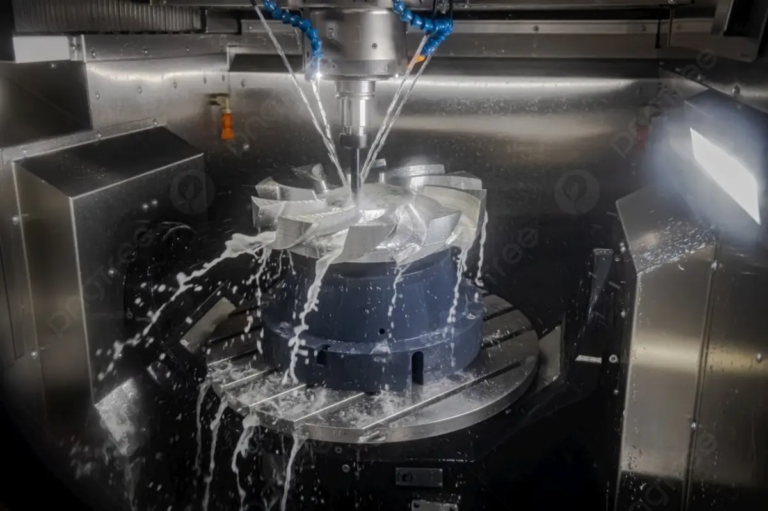

The UBZ-NT gantry machining center is a game-changer in the world of manufacturing. By combining high rigidity and high dynamic performance, this machine offers unparalleled precision and speed. The five-axis configuration makes it an essential tool for complex part production, allowing for precise control and flexibility in even the most demanding manufacturing applications.

Advanced Features for Enhanced Productivity

One of the key features of the UBZ-NT gantry machining center is its modular design. This allows for a wide range of configurations, including a bridge with two blades, two bridges with one blade, and two bridges with two blades. The machine’s flexibility is further enhanced by its tool box options, with up to 20 tools supported by the HSK-63-A tool support and up to 8 tools supported by the HSK-100A tool support.

Superior Performance and Inherent Flexibility

The UBZ-NT gantry machining center is equipped with a pin replacement device, allowing for automatic replacement of high-frequency motor pins with different characteristic curves. This enables the machine to tackle a wide range of materials, including steel, flowing materials, titanium, aluminum, non-ferrous metals, and plastics. The pin replacement device can be easily adjusted to accommodate various tools, ensuring maximum flexibility and versatility.

Advanced Spindle Technology

The machine’s spindle technology is also worth highlighting. With a power range of 19 to 100 kW and a torque of 1200 nm, the spindle is designed to handle demanding tasks with ease. The fork head, with its rigid design and hydraulic tightening device, ensures accurate and precise positioning of the spindle.

Initialize and Optimize

To ensure optimal performance, the UBZ-NT gantry machining center is equipped with advanced control systems. The Fidia C20 machine tool control device allows for precise control and monitoring of the entire process, enabling real-time adjustments and improvements. The machine’s direct measurement system ensures accurate tracking and monitoring of part dimensions, ensuring compliance with industry standards.

Conclusion

The UBZ-NT gantry machining center represents a significant step forward in manufacturing technology. By combining advanced features, superior performance, and inherent flexibility, this machine is poised to revolutionize the way we produce complex parts. With its modular design, advanced spindle technology, and user-friendly control systems, the UBZ-NT gantry machining center is an essential tool for any manufacturer seeking to stay ahead of the curve in today’s fast-paced manufacturing landscape.

Let’s explore the vast possibilities of this cutting-edge machine and see how it can help your business thrive in the world of manufacturing.