Stamping mold is a special process equipment that processes materials into parts (or semi-finished products) during stamping processing.

Classified according to the nature of the process: punches, molds, bending molds, depths, forming molds, etc.

Classified according to the degree of process combination: single-work sequential mold, composite mold, quality entry.

A) Set pattern b) Pull deep pattern C) Border pattern d) Bloat mold

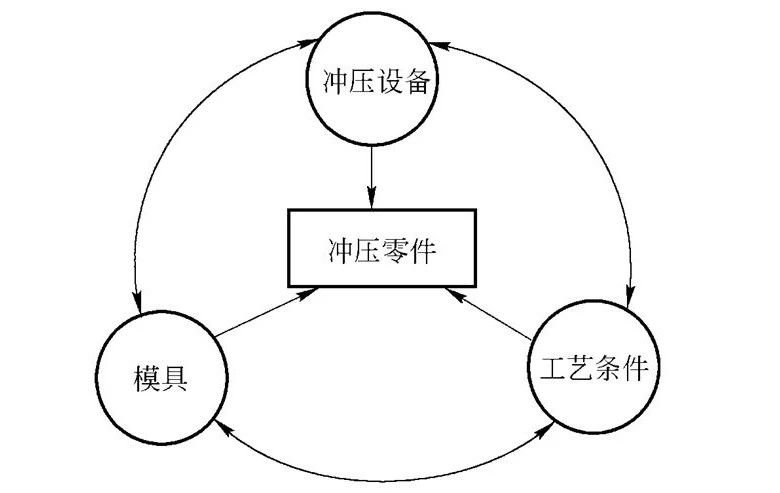

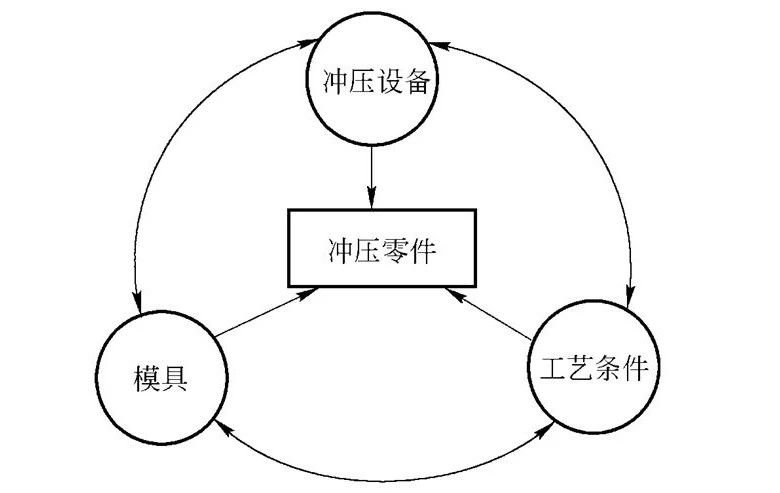

Three elements of stamping production: reasonable stamping process, advanced molds and efficient stamping equipment.

1. Making, punching, edge repair

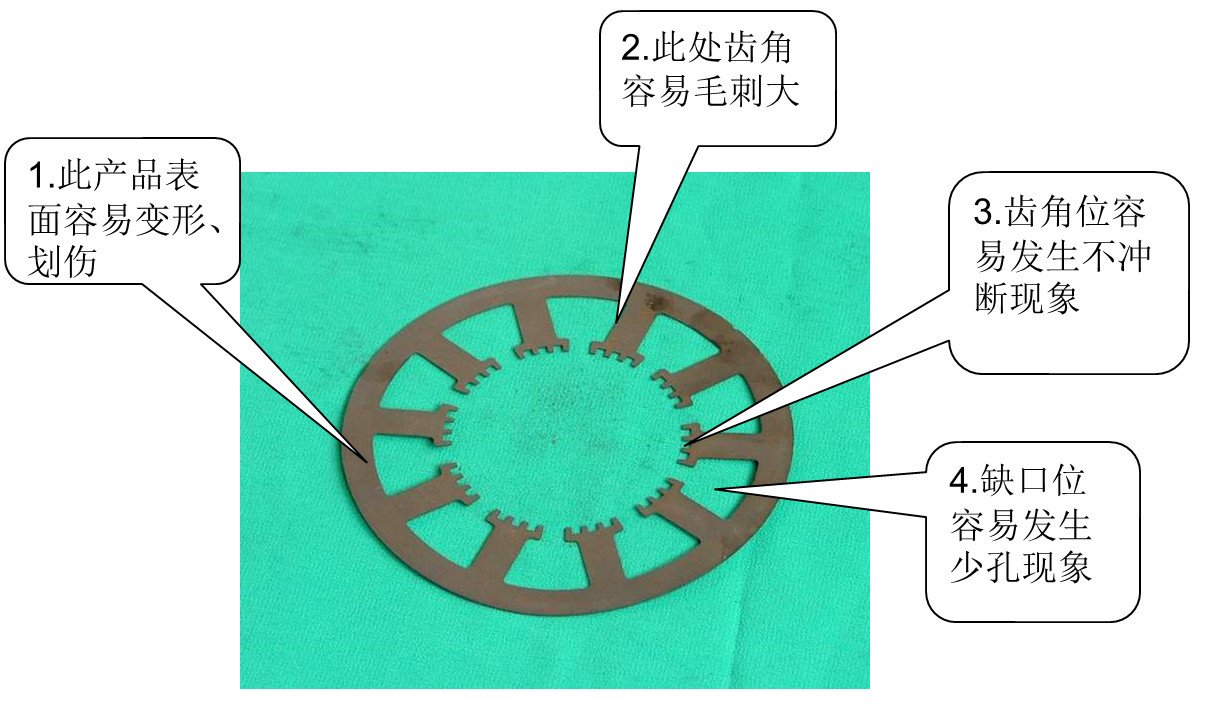

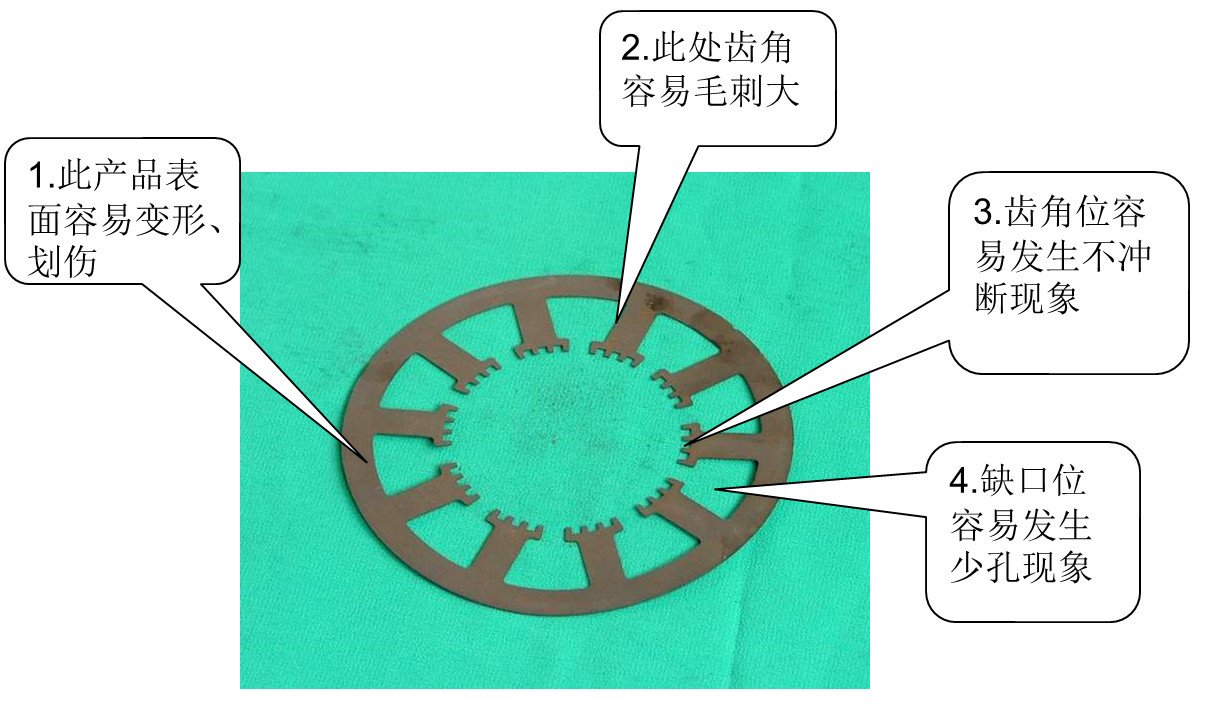

Defect: Excessive burrs, deformation, surface scratching, size inconsistency, small pores, etc.

1) Excessive burrs: too large or too small in the space between the concave mold;

2) Transformation: the height is too small; the compression plate is not good with the concave model surface;

3) Surface stratch: dragging, pulling and other phenomena;

4) The size does not conform to: not in place;

5) Little Pores: Broken by the head; not enough punch length.

Settling, punching and edging products are subject to defect positions

2. Pull extension

La Yan products are subject to fault positions

3. Bring the edge

Defects: The edge is not vertical, the height of the edge is inconsistent, the edge of the edge, the edge cracks, etc.

1) The edge is not vertical: the gap between the convex mold is too large.

2) The edge height is inconsistent: the gap between the convex mold is uneven;

3) Bring hair: the blade mouth has scars;

4) Border crack: terrifyings are great during repair;

Bring products subject to defect positions

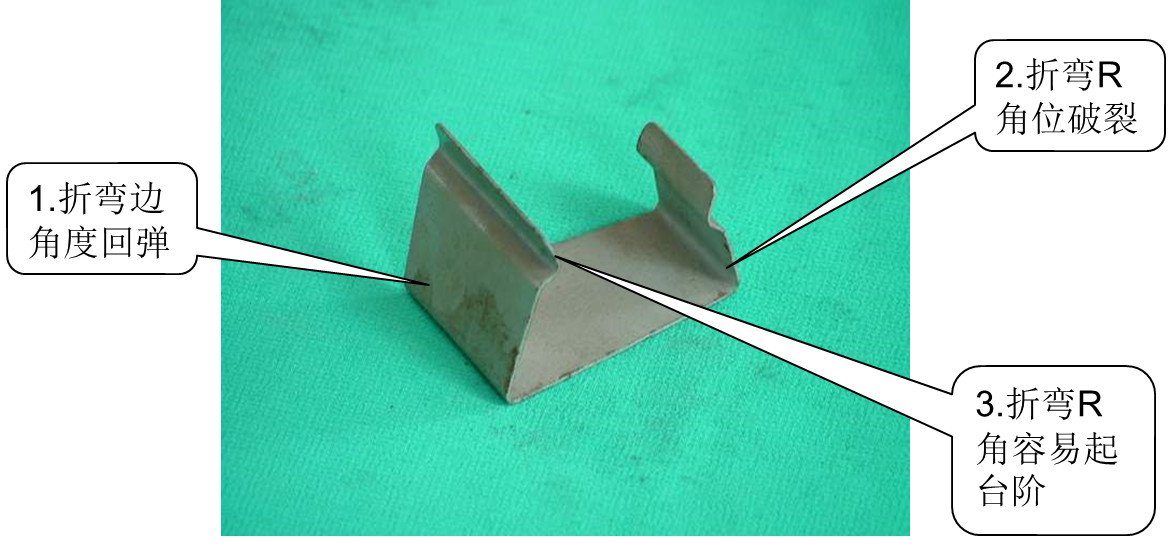

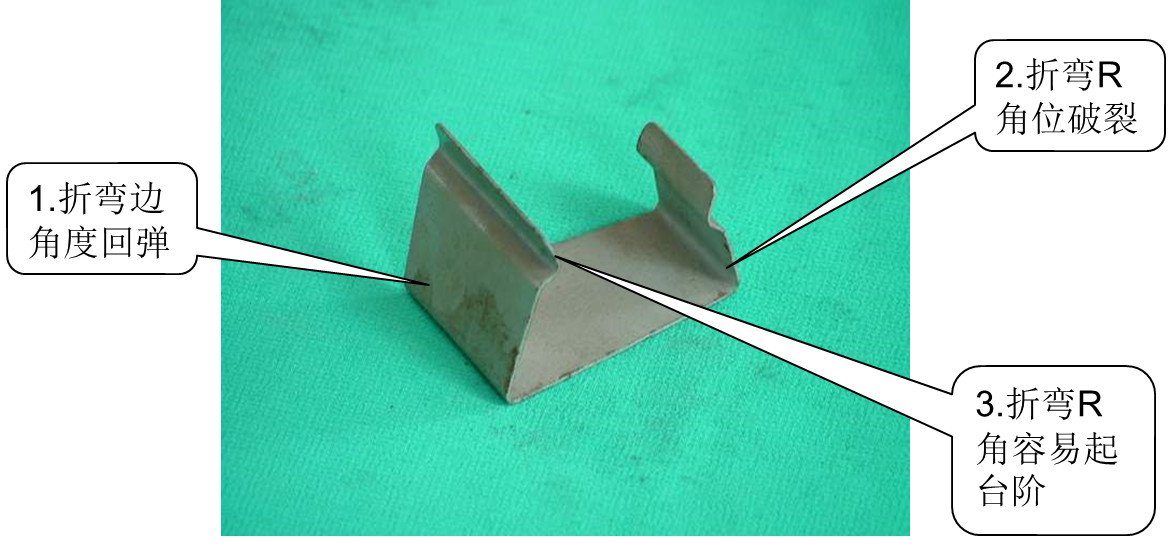

4. Bend

Defects: Unqualified bending angle, bending edge breakage and R pitch corners have steps.

1) Unqualified bending angle: The convex and concave molded gaps are too large, and the convex mold angle is not suitable for the material.

2) Bend the edge break: the space between the convex mold is too small; the bending angle is too small;

3) There are steps in the R horns of bending: the bending angle of the convex mold is too large;

Bending products are subject to fault positions

5. Garbage skipping

1) The length of the punch is insufficient, and the concave mold is cut into a thick and 1mm replacement of the punch by pressing the knife mouth;

2) The gap between the concave mold is too large, cut into the child to narrow the gap or narrow the gap with a cover machine;

3) The glove or model is not removed, and the model or model uses the magnetic device in magnetic.

6. waste -acupoint blogging

1) Small holes or drop holes to increase the landing holes to make the landing material smooth;

2) There is a landing hole drop angle to increase the felling hole to eliminate the chamfer;

3) The knife mouth does not put the cone, thread sleeve or reverse extension to reduce the length of the straight wall;

4) The position of the straight wall of the knife mouth is too long, and the negative drill is crazy to shorten the position of the right wall of the knife mouth;

5) The blade mouth collapses, causing a large forehead, and the ingredients are enriched.

7. Passionate

1) The blade mouth collapses, causing the edge to rise up to the blade mouth;

2) The gap between the tip head and the concave mold is too large, the line is cut into the block, and the gap is reprimanded;

3) Bad and clean concave mold knife, wall polishing knife mouth;

4) There are too small gaps between the punch and the concave mold except the model and the corresponding gap;

5) The upper material is too big.

8. Rating

1) Positioning the positioning of the offset adjustment;

2) There is one-sided molding, the material increases the pressure and the positioning is adjusted;

3) Design errors, causing the uneven knife to move up the embedded cutting edge;

4) Power delivery device is not allowed;

5) Calculate the step distance of the feed rate to re-calculate the step distance and redirect the knife position.

9.

1) The fence height is too low and the jumping head is too long to adjust the fence height;

2) Incorrect material positioning, causing the punching head to cut the single side, adjust the positioning or feeding device due to uneven stress;

3) The bottom cast waste is blocked, causing the jump head to re-drive the large landing holes to make the landing material smooth;

4) The fixed part of the punch (splint) and guide parts are repaired or recoverable into blocks to make the smooth punch (beat board) offset;

5) incorrect orientation of the board, causing the unilateral force of the punch to re-enter and distribute the card gap;

6) The knife mouth is too short and replace it with the interference by the board and increase the length of the knife mouth;

7) The punch is not fixed and the punch is fixed up and down to make it unable to move up and down;

8) Rush the blade of the blade without sharpness;

9) strangling on the surface of the head, unevenly replaced the tap during seasoning;

10) Turning head is too thin, too long, resistance is not enough to change head type;

11) The rigidity is too high, the punch material is not replaced by the punch material, and the heat treatment hardness is adjusted.

10. Tiequ

1) Calculation of pressure tendon position or flexion position;

2) The space between the bend is too small, extract the iron domes to adjust the space or grind it into a block or grind the type formation;

3) Convex bending patterns are too sharp to repair R corners;

4) Too few materials of the knife port;

5) The tendon is too narrow then crushes the pressure tendons.

11. Poor poor

1) The center of the bottom hole of the buds and the center of the buds and the punch will not coincide to determine the correct center position, or move the position of the buds, or move into a pump-edge or even break the position pre-pitch or adjust positioning;

2) The gap between the concave mold is uneven, causing the repair of the height of the pumping edge and the pumping buds to be weak or even broken;

3) The bottom hole of the buds does not meet the requirements, resulting in the height of the buds and re-calculating the diameter of the bottom hole.

12. Bad molding

1) The casting pattern is too sharp, causing the material to crack and shape the R angle into a convex mode, and the R corner is properly repaired at the knife mouth;

2) The length of the molding punch is insufficient, resulting in the formation of failure to calculate the correct length to adjust the actual length of the jump head to achieve the requirements;

3) The molding head is too long, the material of the molding point is deformed, and the correct length of the jumping head is determined, and the actual length of the jumping head is adjusted to meet the requirements of the punch;

4) The material of the molding place is not enough to make the development material cracking calculation, or repair the R angle or reduce the molding height;

5) Improper positioning, resulting in poor positioning or mold feeding device;

6) Gaps that are too small cause cracks or gaps to deform and expand.

13. Folding size

1) The mold error makes the angle error cause the size tone and height to be wrong or wrong;

2) Insufficient elasticity causes wrong angle to cause size deviation to change the spring;

3) The material does not meet the requirements, resulting in the wrong angle causing materials to change size or adjustment gap adjustment;

4) Material thickness deviation causes wrong angle which causes size to be set with thickness, materials change or fit adjustment;

5) Incorrect positioning causes size deviation to adjust the positioning to make the size OK;

6) Design or processing errors cause torrential welding grinding between bending blocks to eliminate the gap between blocks, resulting in a small size of the bending size;

7) There is no angle r of the public formation, and the height of the bending height of the corner of the person of the person of the ring of the public repair is small;

8) The bending size of both sides is large and compressed;

9) Unilateral bending material causes unstable size increase to increase spring force, adjust positioning;

10) unreasonable gaps, causing wrong angle and dimensional deviation to repair the gap;

11) The height of the folding knife is insufficient and the bending head is too short to increase the height of the folding knife, so the bending head is as good as possible to make the troops as much as possible, resulting in poor corner.

12) The speed when bending is too fast, causing the bending root to deform to adjust the speed ratio and choose a reasonable speed;

13) The structure is unreasonable.

14) UNSUBLISHED HARDNESS OF PUBLIC HEAT TREATMENT FORMATION, causing the pressure line or redoing the public pressure line by forming.

14

1) improper positioning or feeding device or feeding device;

2) insufficient forgiving to repair the position;

3) The internal guide columns are tense, causing the internal guide column to malfunction;

4) Chuang head deformation or the surface is not smooth to replace the punch;

5) The main material sales are unreasonable and reinstall the highest material sales position;

6) Insufficient upper force, or not, the removal power is not enough to change the upper spring or cut the spring;

7) The coordination of the punch and the splint plate is not smooth, and the splint plate and the splint can make the combination smooth;

8) The coordination of the training slider is not smooth to repair the slide block and guide slot.

9) Showing the heat treatment of the board, deformation and then grinding the plate after stamping for a period of time, correction and deformation;

10) The punch length or the length of the upper material is not enough to increase the sales length of the upper material or the trades of the appropriate length;

11) change to replace the head;

12) The pattern is not cloud magnetic and the coin brings the pattern to magnetic.

15. Feeding is not smooth

1) The mold is not positive, resulting in the material belt as a feeder and heavy shelf mold or feeder setting on the same straight line;

2) adjust ingredients or replace materials;

3) Do not discharge the flow not referred to the countermeasures to resolve the countermeasures;

4) The positioning is too tight to adjust the positioning;

5) Correct the sales points too tight or the right wall is too long.

6) Poor tip attachment or too long to interfere with the length of the material belt to replace the length of the tip head again;

7) The upper material is too short, and the ingredients and molding formation are interfered with and adjusted the length of the upper material to avoid interference;

8) Improper arrangement of floating block position adjust the position of floating block.

16. Bad riveting

1) Improper expectations of the closed height of the mold and inadequate adjustment to adjust the closed height;

2) The workpiece is not placed and the positioning gap is adjusted;

3) The original preliminary part confirms the pumping holes and refer to the unfavorable solution of the pumping hole to solve the countermeasure treatment to confirm whether the riveting hole is doing works.

4) The length of the riveting tap is not enough to swing to the length of the length;

5) The rivet head does not meet the requirements to confirm and use the rivet head to meet the requirements.

17. Low-out or installation

1) Be careful when you accidentally arrange it;

2) Chongko is marked directionless.

18. Install the wrong screw

1) I don’t know that the model thickness understands that the model thickness is too long or too short;

2) Insufficient screws are not enough and the appropriate screws are selected.

19. Mold Removal

1) If the nail hole is not cleaned, the sales holes are cleaned and the nails are cleaned. Nail hole positioning should be used.

2) Do not touch the nail holes when the mold is not touched when the mold is nailed.

20. Position sales

1) 细心检查销钉孔是否拉毛,否则应将打不出来销孔重新铰孔;

2) Selling bias or there is no additional positioning to sell escape holes.

21. Spring is too long

1) I didn’t pay attention to spring pore depth.

2) Spring dying point with lack of experience and lack of experience.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.