Unlocking precision manufacturing: Hamilton’s CNC machining service

At the heart of Ontario’s industrial landscape, Hamilton is a powerful country in advanced manufacturing. Computer numerical control (CNC) processing is often the cornerstone of success for enterprises seeking to convert raw materials into complex, high-precision components. In this domain, Five-axis CNC machining Represents the pinnacle of versatility and accuracy. This is Great Become a leadership force in Hamilton, providing professional CNC machining solutions to meet the toughest manufacturing challenges.

Beyond the Basics: The Power of Five-Axis Processing

Traditional three-axis machining (moving in X, Y, and Z directions) is effective for many parts. However, complex geometry, complex profiles and tight tolerance features require more agility. Five-axis CNC machining adds two axes of rotation (typically A and B) to the linear motion. This allows the cutting tool to actually go from Any angle In a setting.

Why is this important to you?

- Complexity release: Parts with composite curves, undercuts, deep cavity and features are generated on multiple faces that are impossible or less efficient. Consider aerospace components, complex molds, impellers, medical implants or complex structural components.

- Unparalleled precision: Reducing settings minimizes errors caused by repositioning and manual processing. Maintaining tighter tolerances is always achievable and is critical for demanding applications.

- Enhanced finish: Continuous tool positioning reduces the effect of the stairs at optimal angles and leads to excellent surface quality, often reducing the need for a large number of manual finishes.

- Huge time savings: A complex part that is set up to complete means less machine time, faster throughput and reduced labor. This translates into faster lead times and lower overall production costs.

- Minimized material waste: Fewer setup errors and more efficient tool paths can lead to optimized material use.

Greghime: Hamilton’s Prime Minister’s Five-Axis CNC Machining Partner

Gregtime is not only another machinery workshop. This is a dedicated person Professional five-axis CNC processing manufacturer Equipped with state-of-the-art technology and driven by deep production expertise. They are located in Hamilton and specialize in leveraging this advanced capability Professionally solve complex metal parts manufacturing problems.

What sets the Greatlight in the Hamilton CNC Services Market?

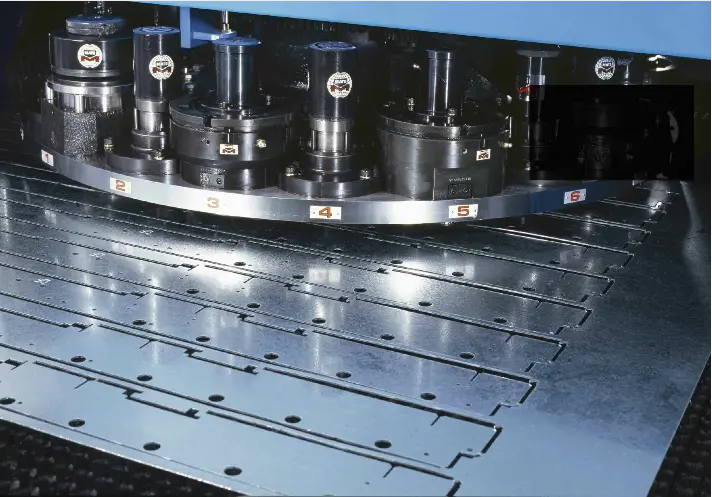

- Advanced Technology: Their facilities feature a cutting-edge five-axis CNC machining center. It’s not just about owning the device; it’s about leveraging the full potential of this technology by mastering complex CAM programming and operational knowledge.

- Material mastery: Whether it is aluminum, steel (carbon, alloy, stainless steel), titanium, brass, copper, plastic or exotic alloys, Greatlight has the expertise of the machine Most materials Effectively. They understand the unique processing characteristics of each material.

- Customized at its core: Is it a large batch or a critical one-time prototype? Great magnificent flourish Custom precision machining. They work closely with their customers to turn unique designs into tangible high-quality parts.

- Speed meets quality: "Quick customization and processing" It is a core commitment. They know that delivery time is crucial and optimized for their advanced features that can effectively deliver high-precision components without sacrificing quality.

- One-stop solution: In addition to the main processing, Grembligh provides Comprehensive post-processing and completion services. This includes the following basic steps:

- Deburring: Clear sharp edges for safety and functionality.

- Surface finish: Options range from basic smoothing to aesthetic polishing, bead blasting, anodizing, electroplating, painting and powder coating.

- Heat treatment and stress relief: Modify material properties for increased strength, durability, or dimensional stability.

- assembly: Simplify the supply chain with basic to complex component services.

- Competitive value: Investing in advanced technology and effective practices can make Greatlame available in Best Priceproviding extraordinary value.

Who can benefit from Greatlight’s Hamilton CNC machining service?

Greatlight solves problems in industries where complexity, accuracy and reliability are unnegotiable:

- Aerospace and Defense: Structural components, engine parts, housings, accessories that require extremely high tolerances and material integrity.

- Medical and Dental: Implants, surgical instruments, diagnostic device components with biocompatible materials and complex geometry.

- Automobile (performance and EV): Engine components, suspension parts, lightweight construction, battery housing, complex prototypes.

- Energy (oil and gas, renewable): Valve body, pump assembly, turbine parts, heat exchangers designed for harsh environments.

- Robots and automation: Precision actuators, joints, sensor housings, housings.

- Industrial Equipment: Custom tools, sophisticated fixtures, drums, gears and gait assembly.

Conclusion: Precision design in Hamilton

Access to advanced, reliable and efficient manufacturing is crucial in a highly competitive global market. For Hamilton businesses and complex metal components that need to be manufactured to the highest standards, working with experts like Greatlight is a strategic advantage.

Their investment The most advanced five-axis CNC machining technologydeep technical expertise across different materials, dedicated to Customization and quick processingand provide Integrated post-processing/complete service Create a compelling one-stop solution. Greatlight’s location itself is not only a supplier, but also a partner that solves complex manufacturing challenges and enables complex designs with precision, speed and cost efficiency. For custom precision machining solutions that require maximum functionality and reliability, Hamilton’s Gregthip CNC machining is undoubtedly the top choice.

Customize your precision parts now at the best prices!

Frequently Asked Questions about Hamilton CNC Processing (FAQ)

Q1: What exactly is five-axis CNC machining and why is it better?

A: Five-axis CNC machining allows cutting tools to move on five different axes simultaneously: three linear (x, y, z) and two rotations (a and b). This allows extremely complex geometry to be machined in a single setup, resulting in higher accuracy, better finishes, shorter production times and the ability to create impossible parts using a 3-axis computer.

Q2: Which material is good?

A: Greglight machines have a variety of materials, usually including a variety of aluminum, steel (carbon steel, alloy steel, stainless steel), titanium, brass, copper and engineering plastics. They can also usually handle more challenging machine-computer alloys. It is best to discuss your specific material requirements directly with them.

Q3: Do you only handle large production runs, or can you create a single prototype?

Answer: Gremplying specializes in research Custom precision machiningwhich includes everything from one-time prototypes and small batches to mass production. Their five-axis capability makes them particularly effective for complex prototypes by reducing the setup time.

Q4: What finishing services does Great Da provide?

A: Greatlight provides a comprehensive range of post-processing and finishing services, eliminating the need for you to coordinate with multiple vendors. This includes surface finishes such as burrs, polishing or bead blasting, anodizing (types II and III), gold plating, painting, powder coating, heat treatment, pressure relief and assembly services.

Q5: How long does it usually take to make parts?

A: The delivery time depends largely on the complexity of the parts, the materials, the required finish and the current workload. But the key advantage of greatness is that they are Quick processing. Their advanced five-axis machines often significantly reduce cycle time compared to the multi-setting method on less functional machines. You will receive a specific schedule based on item details during the quotation period.

Question 6: Why choose a Hamilton-based CNC machining service, such as Greatlime?

A: Choosing a local (Hamilton) provides important advantages:

- communicate: Easier collaboration, clearer technical discussions and faster problem solutions.

- logistics: Reduces shipping time and costs, especially for prototypes or frequent delivery times.

- Support local industries: Invest back into the Hamilton manufacturing community.

- Face-to-face interaction: Possibility of store access to key items (applicable). Greatlight combines these local interests with world-class five-axis precision machining capabilities.